BC pipe break repair – reducing water loss from an indefinable leak for a city in western Canada

A city authority in Canada repair an underground 600mm diameter concrete pipe with a difficult break at the point it passed through a wall, reducing a 2 bar leak losing significant amounts of water down to a slow and steady drip.

Case Study Data

Site

Public Water Network

Location

British Columbia, Canada

Repair Type

Leak Repair

Defect

Crack in a 600mm diameter concrete water supply pipe

Products Used

Sylmasta AB Original Epoxy Putty Stick

Epoxy putty offering excellent wet surface adhesion for sealing pipework which cannot be made dry before repair

SylWrap HD Pipe Repair Bandage

Composite wrap with water activated resin which sets rock hard to reinforce repairs by forming an impact resistant outer sleeve

Case Study PDF

Case Study Details

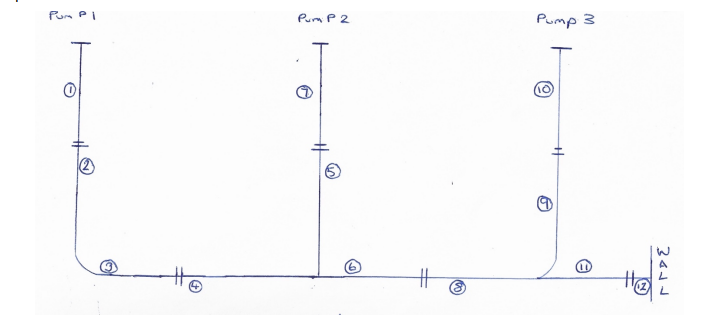

The 600mm diameter pipe ran beneath a road in a city in British Columbia. A break was detected and with other concrete pipe bursts making headline news across Canada, the city authority carried out an immediate excavation to assess the problem and repair the leak.

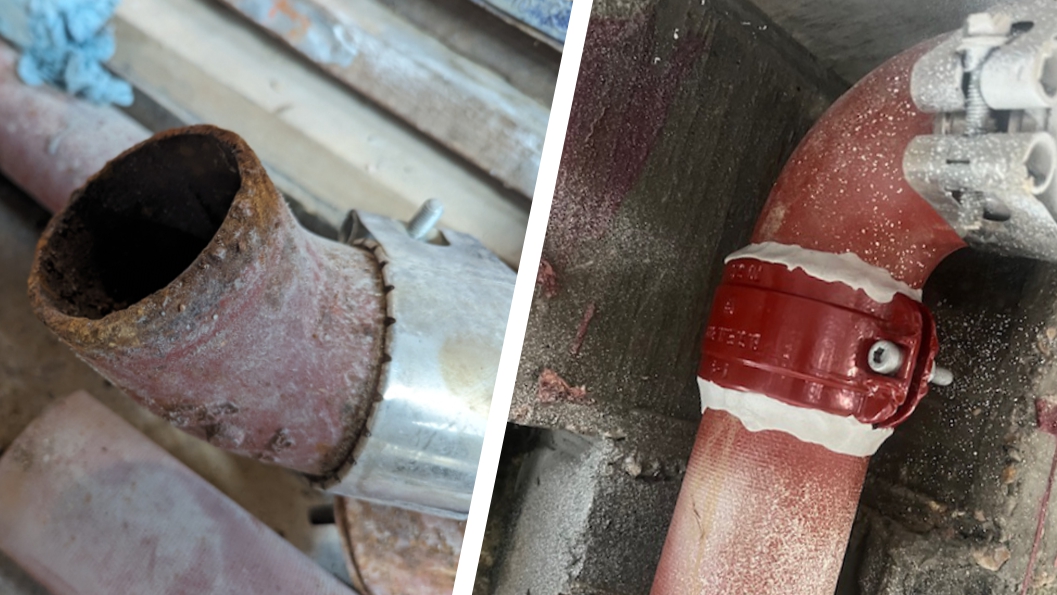

A steady, hard spray of water was discovered jetting out of the pipe through a joint at the exact point the line passed into a solid concrete wall. This made identifying the exact source of the leak impossible.

The city authority contacted Sylmasta for help with what was a very challenging application. Not only was the precise leak point unknown, but the pipe was unable to be fully shutdown.

A further complication came with the break being so close to the wall, meaning the normal live leak repair method of applying Wrap & Seal Pipe Burst Tape would be ineffective.

There was insufficient space to stretch the tape by the required 300 percent to ensure it successfully amalgamated to form a solid rubber band.

Sylmasta suggested reducing the pressure as much as possible from the 2 bar the pipe operated at, followed by using AB Original Epoxy Putty to seal around the entire joint.

AB Original was recommended because it has excellent underwater adhesion, meaning it could bond to the pipe even if wet from the ongoing leak. Its two-hour work time also offers longer to work the putty without worrying about premature curing during application.

The importance of the pipe to the city network meant pressure could only be reduced between midnight and 5am, giving the two maintenance workers making the repair a five-hour window in which to work.

Just under 8kg of AB Original was used in the repair, supplied in 200g sticks. Each stick was mixed by hand until it turned a uniform colour. It was then packed around the leaking joint, building a repair which encompassed the entire break area.

Despite water pouring out the top of the pipe during the repair, AB Original bonded successfully. After two hours, the putty had set to form a watertight material which reduced the amount of water being lost down to a slow drip.

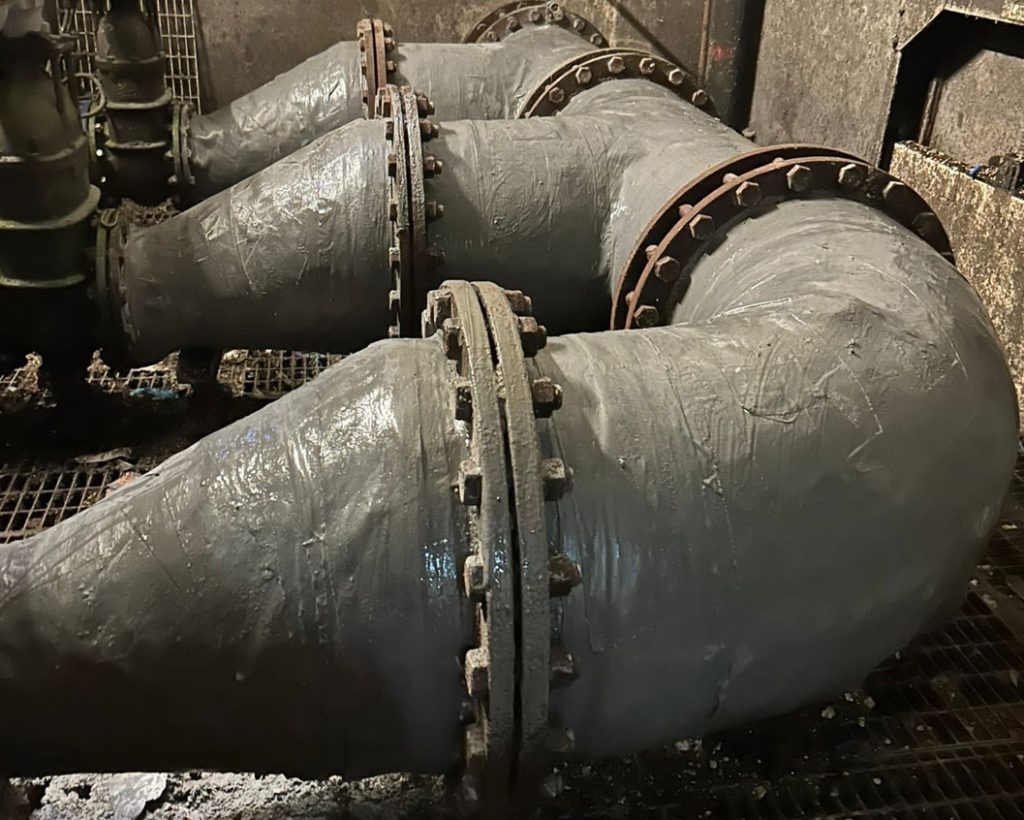

The pipe was then wrapped with SylWrap HD Pipe Repair Bandage for added reinforcement. Two SYL866HD were used, creating a rock-hard outer shell to further protect the pipe and help increase the effectiveness of the repair.

Completing the application took around three hours. The city authority were particularly impressed with Symasta’s efficiency. It took under five days from initial contact for a repair method to be devised, the goods shipped from the UK to British Columbia and the leak reduced to an acceptable level until the section of pipe can be replaced.

The need for speed in addressing the leak before it could escalate into a major problem was particularly important at a time when Canada’s pipe network is under scrutiny following high-profile bursts in Calgary and Montreal which led to flooding and the rationing of public water supplies.

If you have an application you would like to enquire about, then please get in touch

Call: +44 (0)1444 831 459

Email: sales@sylmasta.com