Protection at the pumping station – corrosion prevention measures for a complex ductile pipe system

A water company take corrosion protection measures to avoid the future weakening of a 600mm diameter ductile pipe system with three outlets to isolation valves in an underground pumping station.

Case Study Data

Site

Underground pumping station

Location

UK

Repair Type

Corrosion protection

Defect

600mm ductile pipe showing early signs of surface damage

Products Used

Liquid Metal Epoxy Coating

Brush applied coating which cures to a hard wearing, metallic surface for strengthening pipes and protecting against corrosion

SylWrap Pipe Repair Bandage

Composite repair wrap with water activated resin which sets rock hard to encompass pipes with an impact resistant outer sleeve

Case Study PDF

Case Study Details

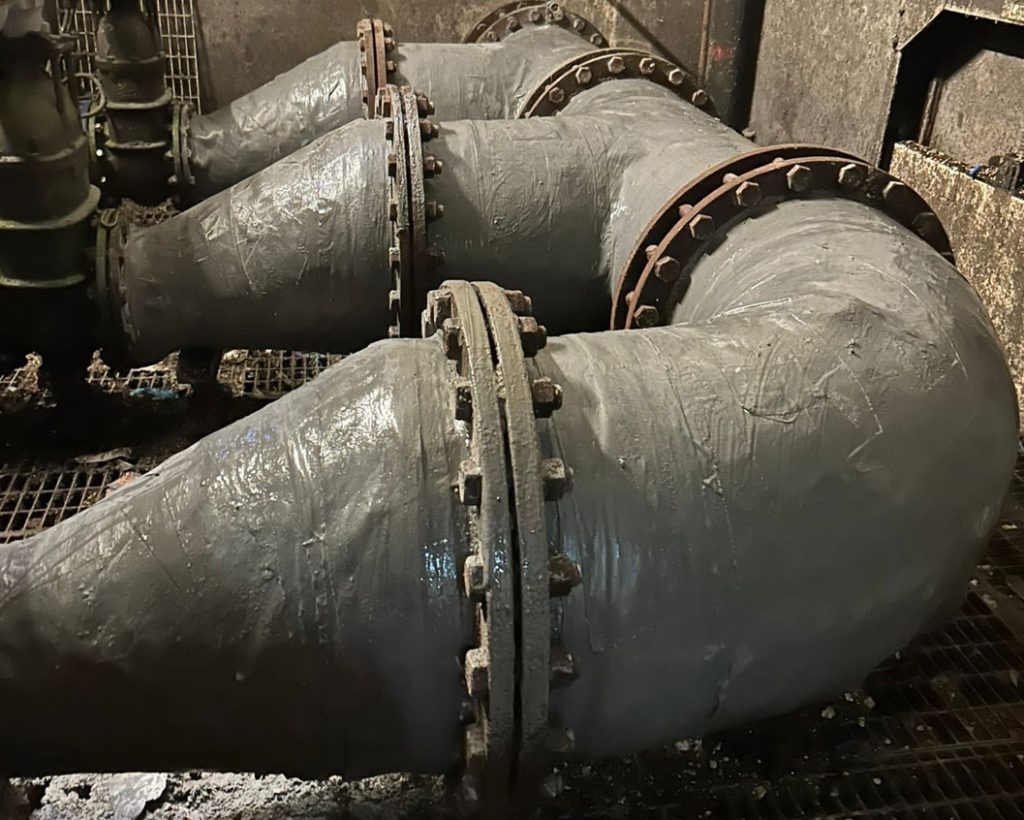

Conditions inside the underground pumping station housing the pipework were damp, grimy and ripe for corrosion. Rainwater, dirt, sand and other contaminates were able to enter the chamber and settle on the pipework.

As a result, the ductile pipe system was beginning to show very early signs of exterior surface damage. This was of particular concern to the water company operating the pumping house because of the complexity of the pipework and the issues that would come in the event of heavy corrosion developing.

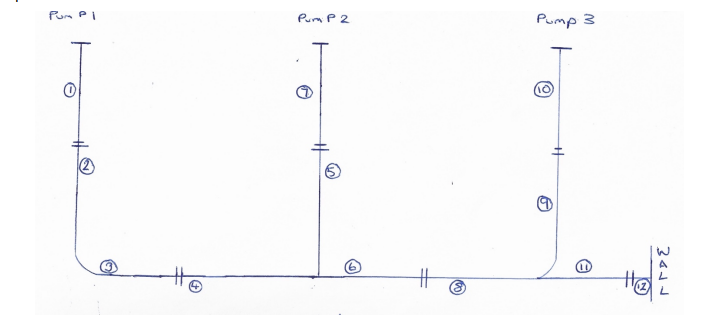

The main section of pipe entered the chamber through a wall. It was five metres long with three flanges at equal intervals. The three outlets branching off were two metres in length, had one flange each and a reducing spool to 200mm diameter at the isolation valves.

Carrying out any sort of leak repair or replacing sections of the system would present a serious challenge. Instead, the water company sought enhanced corrosion protection measures for the ductile pipe to lessen the chances of the line becoming breached.

Rust and dirt were cleaned from the pipe before it was coated with Liquid Metal Epoxy Coating. Liquid Metal is brush applied and cures to form a smooth, metallic, hard-wearing outer surface which acts as a shield against external corrosion.

The entire main section of pipe, the three outlets, reducing spools and all six flanges were painted in Liquid Metal. The protective layer provided by the epoxy coating was then further reinforced using SylWrap Pipe Repair Bandage.

SylWrap Bandage is a composite wrap with a water-activated resin. It is wrapped and smoothed around pipework, curing in minutes to provide a rock-hard, impact resistant layer of protection.

The engineers carrying out the repair wrapped all sections of the pipe system in four layers of SylWrap, running the Bandage as close to the flange plates as possible to ensure maximum coverage.

Despite the space constraints where the pipe ran close to the floor, the engineers were still able to successfully apply SylWrap around the bottom of the line. Once SylWrap had been applied, another coating of Liquid Metal was added over the top as an additional corrosion prevention measure.

With the repair completed, the water company could now be satisfied that the two coatings of Liquid Metal and several layers of SylWrap Bandage would offer robust protection for the ductile pipe against corrosion.

If you have an application you would like to enquire about, then please get in touch

Call: +44 (0)1444 831 459

Email: sales@sylmasta.com