The alcohol line repair which had a sugar mill in Costa Rica raising a glass of guaro to the SylWrap Pipe Repair Contractor Case

Having a SylWrap Pipe Repair Contractor Case on site enabled a sugar mill in Costa Rica to make an instant live leak pipe repair when a pinhole was discovered in an alcohol line running vertically up a tower.

Case Study Data

Site

Sugar mill

Location

Costa Rica

Repair Type

Live leak pipe repair

Defect

Pinhole leak in 70mm alcohol line

Products Used

Wrap & Seal Pipe Burst Tape

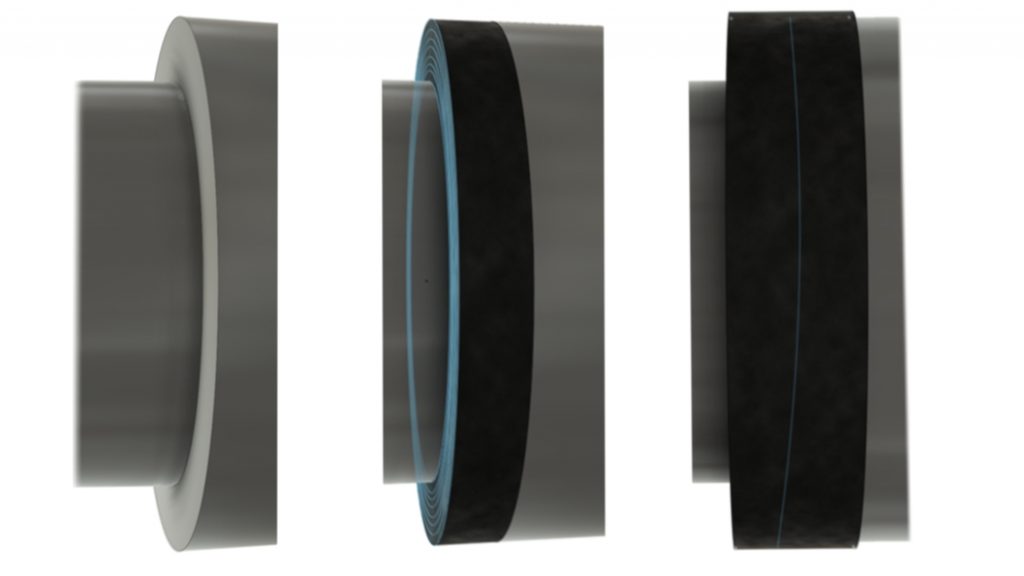

Self-amalgamating silicone repair tape seals live leaks by fusing together to form a solid rubber band

SylWrap HD Pipe Repair Bandage

Water-activated composite wrap which sets rock hard to reinforce and protect repairs

SylWrap Pipe Repair Contractor Case

Products were part of a Contractor Case kept on-site, capable of making up to six live leak repairs

Case Study PDF

Case Study Details

A SylWrap Pipe Repair Contractor Case contains enough products to seal up to six live leaks, making it the ideal kit to keep on-site for rapid response to emergences. The sugar mill had approved its use several years earlier, since when repairs had been made to multiple sections of pipework.

These included 90 degree elbow bends in elevated pipelines and a particularly challenging Y-joint leaking from the exact point where three separate pipes connected. Most of these pipes carried hot water.

The leaking alcohol line was 70mm in diameter and transported alcohol juice extracted from sugar cane during fermentation, which would eventually be used in the production of spirits including rum and guaro, the official liquor of Costa Rica.

It ran vertically up the tower, with the leak developing in a weakened section as the line passed through a circular hole in one of the upper floors. Alcohol juice was left spraying through the pinhole at around two bar pressure.

As the pipe could not be isolated, Wrap & Seal Pipe Burst Tape was used as the leak sealant. Wrap & Seal is made from self-amalgamating silicone. When stretched by up to three times its length as it is wrapped around a pipe, the Tape fuses to form a solid rubber band capable of sealing live leaks .

Despite the space constraints around the pipe where it passed through the hole in the floor, the engineer making the repair managed to stretch the Tape to a suitable length so that it amalgamated successfully.

Once the engineer was satisfied the leak had been fully arrested and alcohol was no longer escaping, a SylWrap HD Pipe Repair Bandage was applied over the top to reinforce the Wrap & Seal.

SylWrap HD is a composite repair wrap containing a water activated resin. As it was wrapped and smoothed around the Wrap & Seal, it cured to form a rock-hard protective sleeve over the pipe.

Both Wrap & Seal and SylWrap HD have WRAS approval, meaning they are safe to use with drinking water. The sugar mill were therefore reassured that neither product would affect the alcohol juice inside the pipe.

Because the plant already had all the products required to repair the pipe on-site in their Contractor Case, it took less than 20 minutes to seal the alcohol line from the moment the pinhole was discovered.

Only a minimal amount of alcohol juice escaped thanks to the speed and ease of the repair. All systems remained fully operational, meaning there was no disruption whilst the application took place.

Had a Contractor Case not been available, a much greater quantity of juice would have been lost. The mill may have even been forced to shut down the leaking section until such time as it could be repaired at significant cost both financially and to production.

If you have an application you would like to enquire about, then please get in touch

Call: +44 (0)1444 831 459

Email: sales@sylmasta.com