Water fountain repair cracked – putting the pieces of a favourite garden ornament back together

A tiered composite stone water fountain in a Welsh garden undergoes a DIY repair after winter temperatures caused water left inside the upper bowl of the ornament to freeze, cracking it into multiple pieces.

Case Study Data

Site

Garden

Location

Wales

Repair Type

High-strength bonding and stone repair

Defect

Composite stone water fountain cracked into multiple pieces

Products Used

Sylmasta Rapid 5 Minute Epoxy Adhesive

Epoxy adhesive with a 5 minute work time which creates high-strength, permanent bonds between all materials

Sylmasta AB Original Epoxy Putty

Hard-wearing epoxy putty used to fill gaps and replace missing sections of damaged stonework

Case Study PDF

Case Study Details

The water fountain consisted of two tiers and was made from composite stone. When winter temperatures in Wales plummeted below -10°C, the upper bowl cracked into several pieces due to water inside it freezing.

When Spring arrived, the owner of the water fountain decided to try and repair and restore their favourite ornament. Not only did the upper bowl need to be bonded back together, but there were numerous other cracks and missing sections requiring attention.

Sylmasta advised that Rapid 5 Minute Epoxy Adhesive be used first to reassemble the fountain. Rapid 5 Minute creates high-strength, permanent bonds between many materials, including composite stone.

The five-minute cure meanwhile is long enough for parts to be carefully assembled and rearranged if necessary before the adhesive sets, at the same time as requiring minimal holding or clamping.

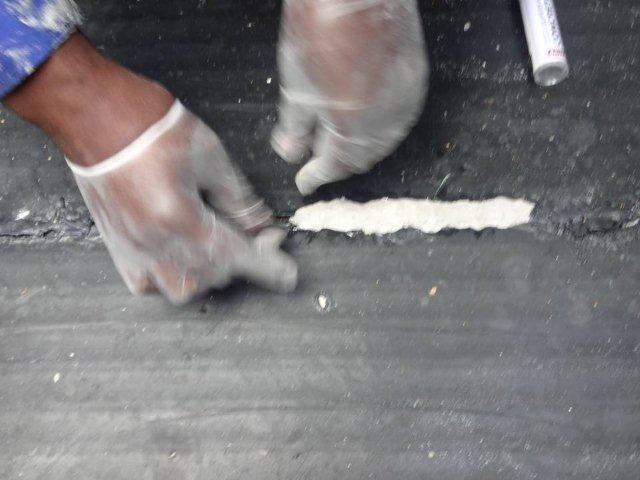

Rapid 5 Minute comes with the two components that make up an epoxy adhesive – resin and hardener – kept separate. The 25ml cartridge extrudes the parts in equal measures, after which they are mixed together for around 30 seconds with a spatula.

The fountain owner extruded the epoxy onto a piece of cardboard for mixing. The mixed adhesive was then applied using the spatula to one of the surfaces to be bonded, and the pieces pushed together and held in place.

Any overspill of epoxy was thoroughly cleaned off the stonework. Rapid 5 Minute exposed to sunlight can yellow with age, which would have looked unsightly against the pale coloured fountain.

After five minutes, the stonework no longer needed to be held together as Rapid 5 Minute had begun to set. The fountain was left undisturbed for a further 30 minutes, allowing the epoxy adhesive to reach maximum properties.

Once the upper bowl had been reassembled, any remaining cracks and missing sections were filled in using Sylmasta AB Original Epoxy Putty. AB Original is a hard wearing, waterproof, ceramic-filled putty which bonds to all materials.

It offers a two-hour work time, enabling the putty to be mixed, moulded into shape and applied without any worry about premature curing. It is suitable for use in interior or exterior settings and achieves a full cure in 24 hours.

The putty was kneaded by hand until a uniform colour. It was then shaped and formed to replace missing areas of stonework and pushed into cracks. For shallow cracks, the surface of the curing putty was wetted whilst still pliable to create a type of slurry which could be worked further in.

To help disguise larger sections of AB Original, powdered dust from the stonework was pressed into the putty. This took it from its standard off-white towards and towards the colour of the fountain, helping the repaired areas blend in.

The fountain owner even discovered that painting yoghurt onto the fountain helped further disguise the repair by encouraging lichen and moss to grow. The distressed touch this added was in keeping with the original stone.

Once the repair and restoration had been completed, the end result was a robust and fully watertight upper bowl. The fountain could go back into use for the summer with any visitors to the garden none the wiser that just a few months earlier, it had been cracked into multiple pieces.

If you have an application you would like to enquire about, then please get in touch

Call: +44 (0)1444 831 459

Email: sales@sylmasta.com