Contractor Case calling – the cement coated steel pipe repair carried out by engineers in Mexico equipped for every leak

An underground cement coated steel pipe on a water network in Mexico undergoes a live leak repair after excavation followed by the removal of the outer coating revealed a 80mm long split in the line.

Case Study Data

Site

Underground water network

Location

Mexico

Repair Type

Live leak pipe repair

Defect

80mm split in a cement coated steel pipe carrying potable water

Products Used

Wrap & Seal Pipe Burst Tape

Self-amalgamating repair tape which seals high pressure live leaks by fusing together to form a solid rubber band

SylWrap HD Pipe Repair Bandage

Water-activated composite wrap which sets rock hard, providing an effective replacement for the removed cement coating

SylWrap Pipe Repair Contractor Case

Products were supplied as part of a Contractor Case, capable of making up to six live leak repairs

Case Study PDF

Case Study Details

A potential leak was identified on a section of the water supply network running beneath a street. Excavation took place and revealed a cement coated steel pipe suffering from a crack around 15mm wide across the diameter of its outer coating.

There was no sign that any water had escaped through this crack. To inspect the condition of the pipe inside, engineers removed the cement using a hammer and chisel. As the coating was chipped away, water began spraying out from a 80mm long split in the steel pipe.

By the time the cement coating had been fully removed from around the leak area, enough water had escaped into the excavation hole to half-submerge the pipe. There was no means of isolating this section of the network and so the only option was to make a live leak repair.

The specialist company involved in the identification of the leak and excavation of the pipe equip all their engineering teams with SylWrap Pipe Repair Contractor Cases, meaning everything needed to seal the pipe was already on-site.

Contractor Cases contain enough WRAS approved products to make up to six permanent live leak repairs to pipes of all diameters and materials. WRAS approval was necessary for this application because the pipe carried potable water.

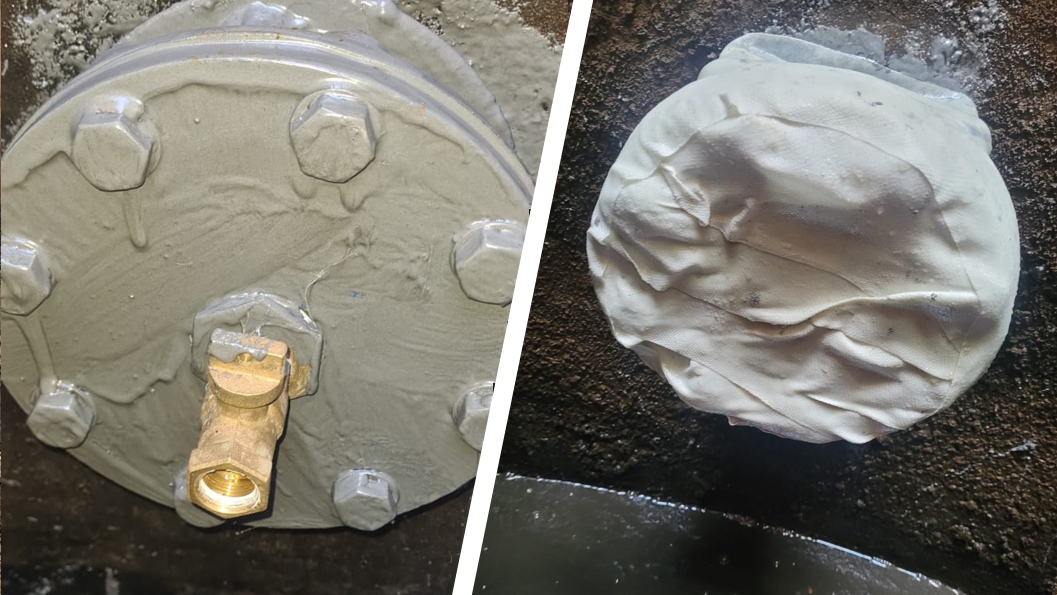

A bucket was used to remove enough water from the hole to enable the repair to take place. Wrap & Seal Pipe Burst Tape was used to seal the leak in the line, with several Tapes applied to cover the entire length of the split in the steel.

When stretched and wrapped around a pipe, Wrap & Seal fuses to itself to form a solid rubber band. Multiple Tapes can be applied over each other to build pressure resistance up to 30bar. For this repair, the requirement was around 3bar.

Enough Wrap & Seal Tapes were applied until the leak had been fully arrested. A SylWrap HD Pipe Repair Bandage was then wrapped over the top for the purpose of reinforcing and protecting the initial repair.

SylWrap HD is a composite wrap with a water-activated resin. After being wrapped and smoothed around the pipe, the bandage set rock hard in minutes. The impact resistant sleeve formed by SylWrap provided an effective replacement for the removed cement coating.

The application was completed in under an hour. Having all the products required to repair the cement coated pipe ready and available via the Contractor Case made a significant difference to response time and how quickly the leak could be sealed, reducing the amount of water lost and disruption to supplies.

If you have an application you would like to enquire about, then please get in touch

Call: +44 (0)1444 831 459

Email: sales@sylmasta.com