Ending a potentially explosive situation – Sylmasta provide reinforcement for pipe elbows following a blowout in a valve chamber

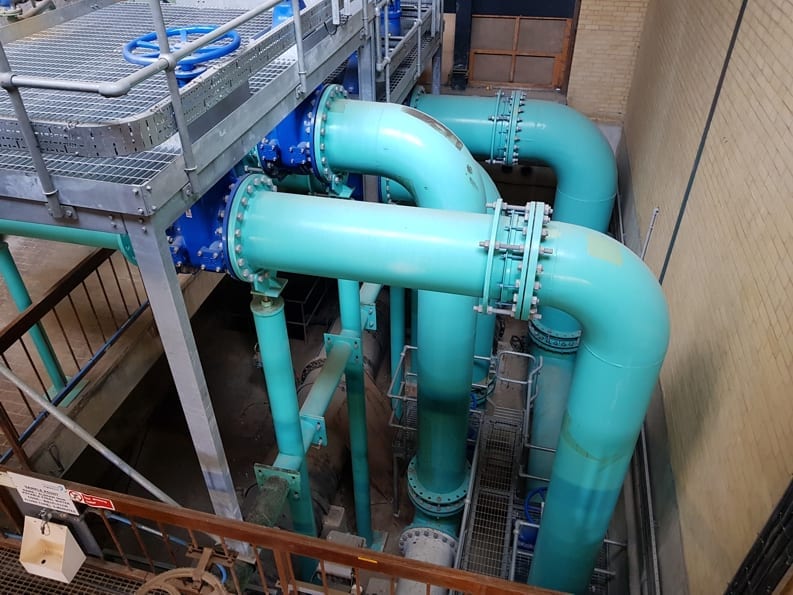

A blowout in a valve chamber in Grimsby, United Kingdom, alerted a water company to the fact that numerous 22 degree 450mm cast iron pipe elbows were below specification and required urgent reinforcement to prevent further incidents occurring.

Case Study Data

Site

Valve Chamber

Location

Grimsby, United Kingdom

Repair Type

Elbow joint reinforcement

Defect

Below specification 22 degree elbow joints on 450mm cast iron water mains

Products Used

Liquid Metal Epoxy Coating

Offered protection to the pipework from factors such as corrosion and created a PCC-2 compliant load transfer layer with SylWrap HD.

SylWrap HD Pipe Repair Bandage

10 layer application reinforced each elbow joint by providing an impact-resistant protective sleeve.

Case Study PDF

Case Study Details

Numerous large diameter water mains made from cast iron were operated by the water company with most of these approximately 50 years old.

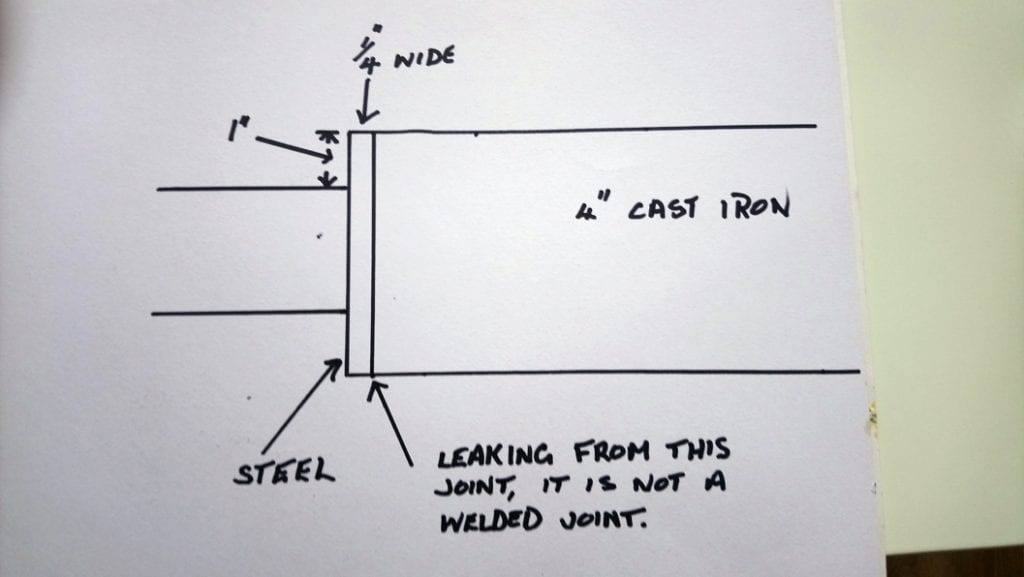

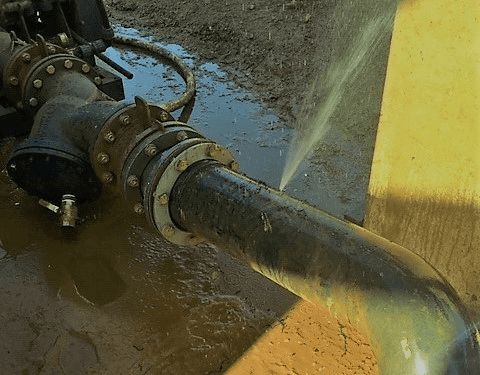

After an incident in a valve chamber in Grimsby where a 22 degree bend on a 450mm main blew apart, analysis of the cast iron showed that the original castings were below specification.

The incident was believed to have occurred when the water main pump from the reservoir to the treatment works stopped and the non-return valve closed, causing a pressure surge which peaked at 10 bar from zero.

Analysis of the cast iron pieces showed no corrosion along the crack lines. The blowout was therefore most likely caused by the low strength of the original casting which had a hardness of only 107.

To prevent similar incidents occurring again, the water company needed to carry out reinforcement of all remaining pipe elbows of the same specification.

The length of the repair area was 350mm between flanges and the application needed to withstand 8 bar operating pressure with fluctuations up to the 10 bar which had caused the original blowout.

Sylmasta advised using Liquid Metal Epoxy Coating and SylWrap HD Pipe Repair Bandage to strengthen the elbow joints against future pressure surges and other factors including corrosion.

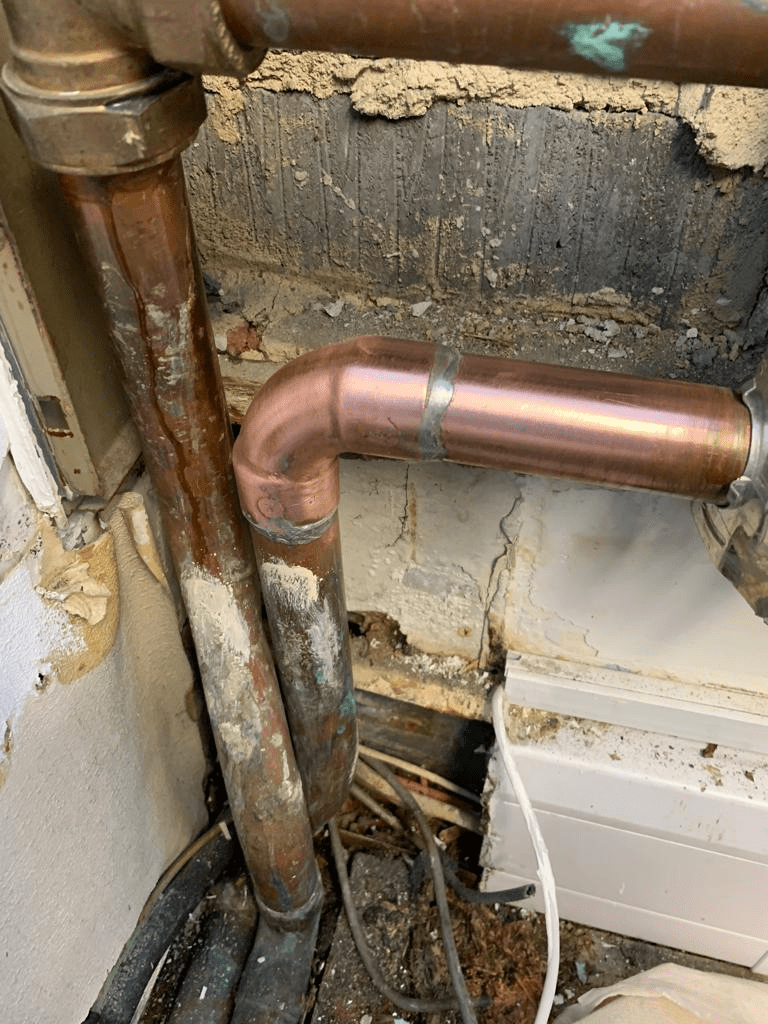

Each pipe was cleaned prior to being coated with Liquid Metal, a metal-filled brushable epoxy which sets to a smooth, metallic, hard-wearing surface over pipework.

Coating the elbow joints with Liquid Metal provided corrosion protection and improved adhesion between the pipework and the SylWrap HD Bandage, creating a PCC-2 compliant load-transfer layer.

10 layers of SylWrap HD were then applied over the Liquid Metal. SylWrap HD is a composite repair wrap with a water-activated resin which sets rock hard in minutes, providing reinforcement to pipework pressure resistant to 30bar.

Each elbow joint could be reinforced in two to three hours and there was no need to turn off the water supply to complete an application. Sylmasta’s repair saved the water company considerable money compared to replacing the below specification pipework and the necessary shutdown of equipment.

After the repair, the strategic water operations manager told Sylmasta: “The wrapping materials have proved central to our project in securing the structural condition of some 22 degree bends found to be in weak condition.”

“The early success of the project in Grimsby has seen it already adopted by other sites in our network, with Hartlepool also happy with it as a preventative measure and more to follow.”

If you have an application you would like to enquire about, then please get in touch

Call: +44 (0)1444 831 459

Email: sales@sylmasta.com