No need to grin and bear wear and tear – the worn shaft repair to avoid a whole new mill wheel being installed at ceramic factory

After being told that disassembling a mill wheel to replace a damaged shaft was too complex and that the only solution was therefore a new wheel, a ceramic company in Mexico instead sought to repair the worn part without taking the system apart.

Case Study Data

Site

Ceramic factory

Location

Mexico

Repair Type

Damaged part rebuild

Defect

Mill wheel shaft badly weakened by abrasion

Products Used

Titanium Supergrade Epoxy Paste

Epoxy paste with high compressive strength and extreme temperature resistance for repairing and rebuilding worn parts

Case Study Details

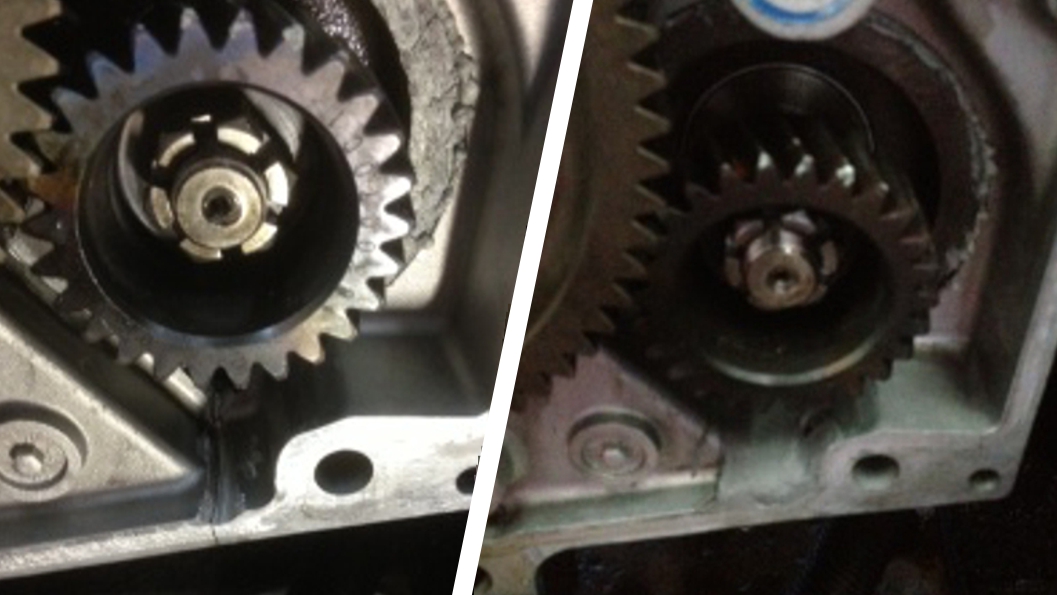

The 150mm shaft was part of a mill wheel at a production plant operated by a company specialising in ceramic, glass and concrete manufacturing. Such abrasive work had left the shaft suffering from extreme wear after years of service.

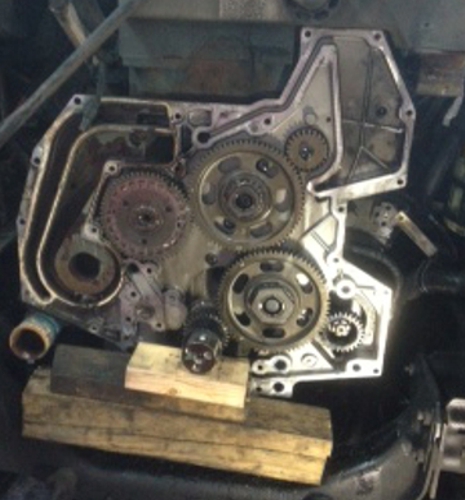

When the company consulted experts about replacing the shaft, they were told it was too complex. To remove the damaged part and fit a replacement, the entire wheel would have to be disassembled. The size and weight of the wheel meant that this was impossible.

Even if the wheel could be taken apart, there was a danger that once dismantled it may be reassembled incorrectly and fail to work. There was nobody with the technical knowledge to carry out such an application because it had never been tried before.

The company were therefore told that the only solution was to remove the existing wheel and fit an entirely new system. Given that the only fault was with the shaft and the rest of the wheel was in good working order, this seemed like an unnecessary waste of time and resources to the company.

Instead, they sought a method of repairing the worn shaft without taking the system apart. Sylmasta recommended the use of Titanium Supergrade Epoxy Paste to rebuild the outside of the shaft, which had been worn away and damaged by abrasion.

Titanium Supergrade was chosen because of its high compressive strength. It also offers extreme temperature resistance up to 250°C. It is reinforced with corrosion-resistant metal platelets which give it a smooth finish.

An extreme mechanical clean was carried out to the shaft prior to the repair. This removed rust, dirt, grime and other materials which had coated the part over its life.

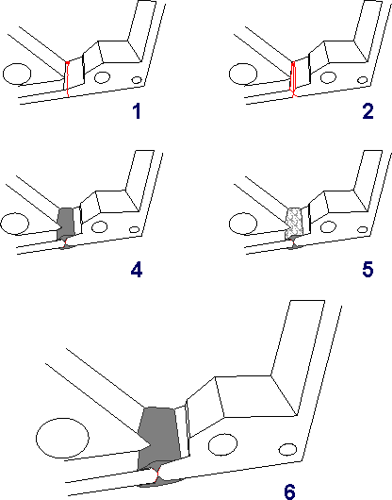

As soon as the preparation was completed, Part A and Part B of the epoxy paste were mixed together. Titanium Supergrade has a work time of three hours, allowing for careful application without the threat of premature curing.

Once successfully mixed, the paste was applied around the entire shaft. A putty knife was used to first push it into imperfections on the shaft, filling all areas of damage.

After the damage had been repaired, further paste was applied to rebuild the shaft by several millimetres. When abrasion now occurred, it would be the new material formed by Titanium Supergrade wearing away, rather than the metalwork of the original shaft.

In this way, Titanium Supergrade offers a long-term solution. Further epoxy paste can be applied to rebuild the worn shaft again when the existing repair wears through, keeping the part operational for as long as the wheel remains in service.

A full cure was achieved in 24 hours, after which the system went back into operation. The repair helped the company save a huge amount of money compared to the suggested solution of replacing the entire mill wheel.

The company are now planning to use Titanium Supergrade to rebuild other worn machine parts across their production facilities instead of replacement wherever possible.

If you have an application you would like to enquire about, then please get in touch

Call: +44 (0)1444 831 459

Email: sales@sylmasta.com