Leak repair made using Sylmasta products withstands 30 bar pressure in qualification tests for ASME PCC-2 402-III

Superfast Aqua PW Epoxy Putty and SylWrap HD Pipe Repair Bandage make a leak repair qualified to ASME PCC-2 Appendix 402-III – Validation for Repair of Leaking Component by withstanding 30 bar pressure in multiple tests.

Case Study Data

Site

Sylmasta HQ

Location

United Kingdom

Repair Type

Leak repair

Defect

25mm hole in 110mm diameter carbon steel pipe

Products Used

Superfast Aqua PW Epoxy Putty

Fast working epoxy putty which bonds to wet surfaces with WRAS approval for sealing holes and cracks in pipes

SylWrap HD Pipe Repair Bandage

Composite repair wrap with water activated resin sets rock hard to reinforce pipework with a thickened, impact resistant sleeve

Case Study PDF

Case Study Details

ASME PCC-2 Appendix 402-III – Validation for Repair of Leaking Component is a test which assesses the ability of a composite pipe repair system for sealing leaking pipes, tanks and vessels containing non-hazardous fluids operating below 10 bar.

To qualify for ASME PCC-2 402-III, a repair must successfully seal a leaking pipe which has been fully breached, restore pressure-retaining capability to the line and show it will not degrade or be compromised over time under service conditions.

It is a standard widely used across many industries – such as water utilities – to give confidence that repairs on the public supply network will be strong and long-lasting.

ASME PCC-2 402-III is also applicable to other industries where high-pressure water pipes are used – such as desalination plants and cooling systems at oil refineries, power stations and food and beverage production.

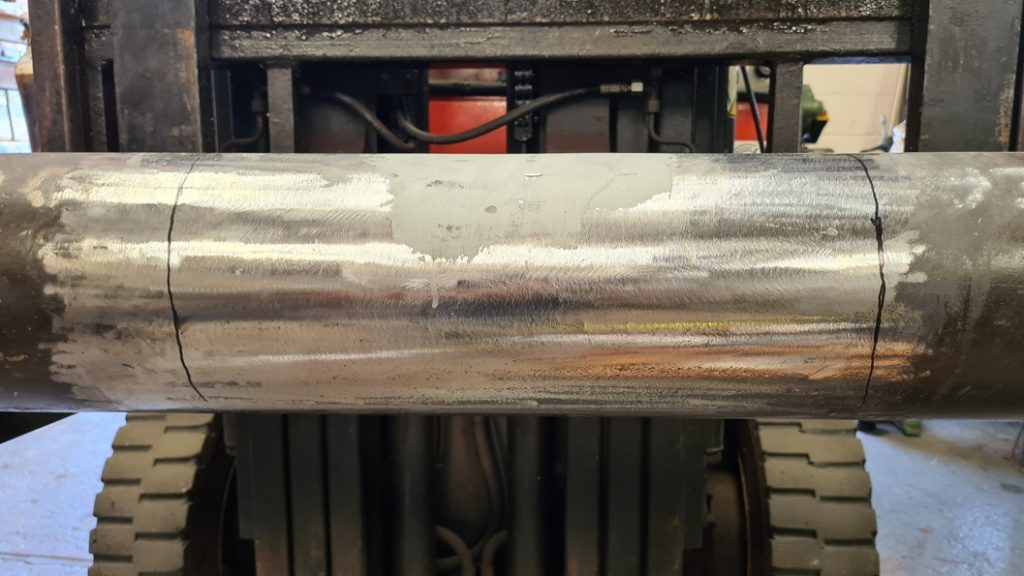

Testing took place at Sylmasta HQ in the United Kingdom. A 25mm hole was cut into a 110mm diameter carbon steel pipe. The leak needed to be sealed before being subjected to three separate pressure tests up to 30 bar.

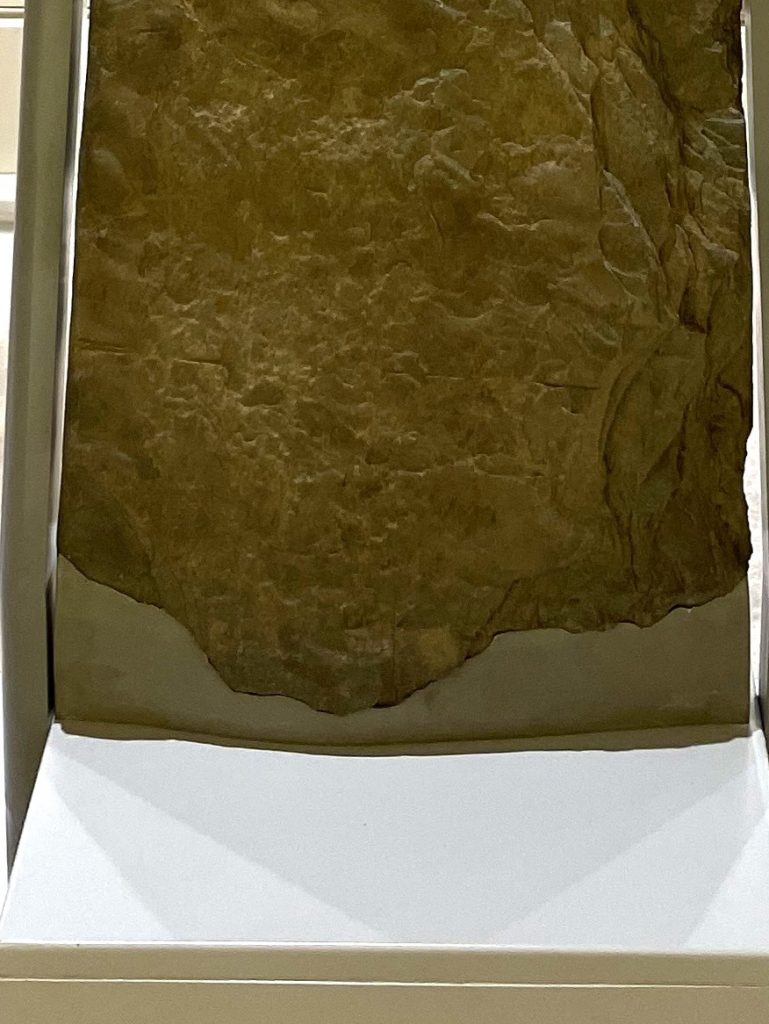

Superfast Aqua PW Epoxy Putty was used to plug the hole in the pipe. To improve adhesion, the pipe was abraded first. This removed any traces of rust, dirt or grime. It also created a textured surface for the repair to grip onto.

The putty was mixed by hand and formed into a disc around 75mm in diameter, ensuring total coverage of the leak. It was placed over the hole and pushed firmly down onto the pipe for maximum contact.

At the edges, the putty was smoothed off using a little water to remove any step from the surface. It was allowed to cure for around 10 minutes until gelled but not hardened.

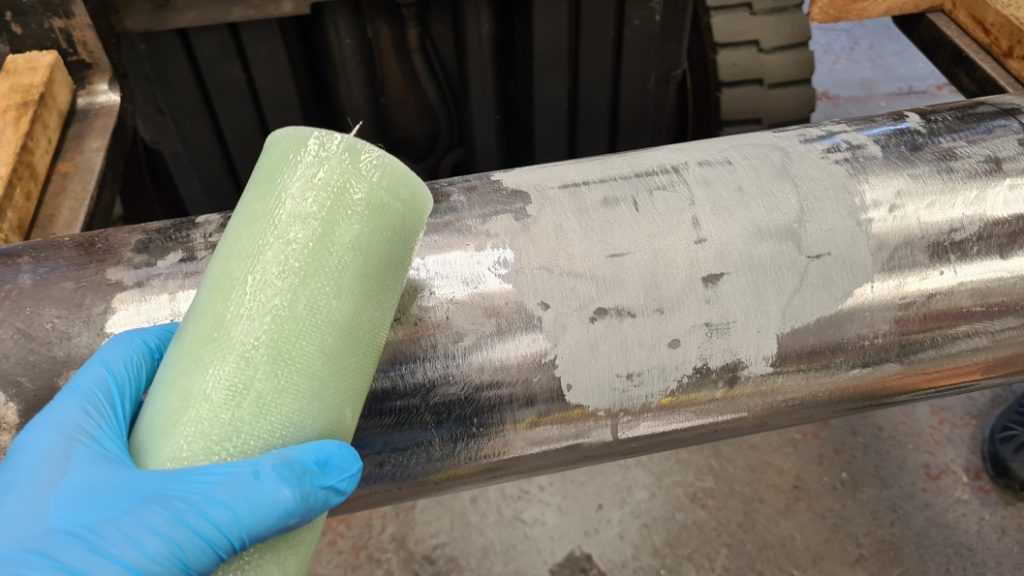

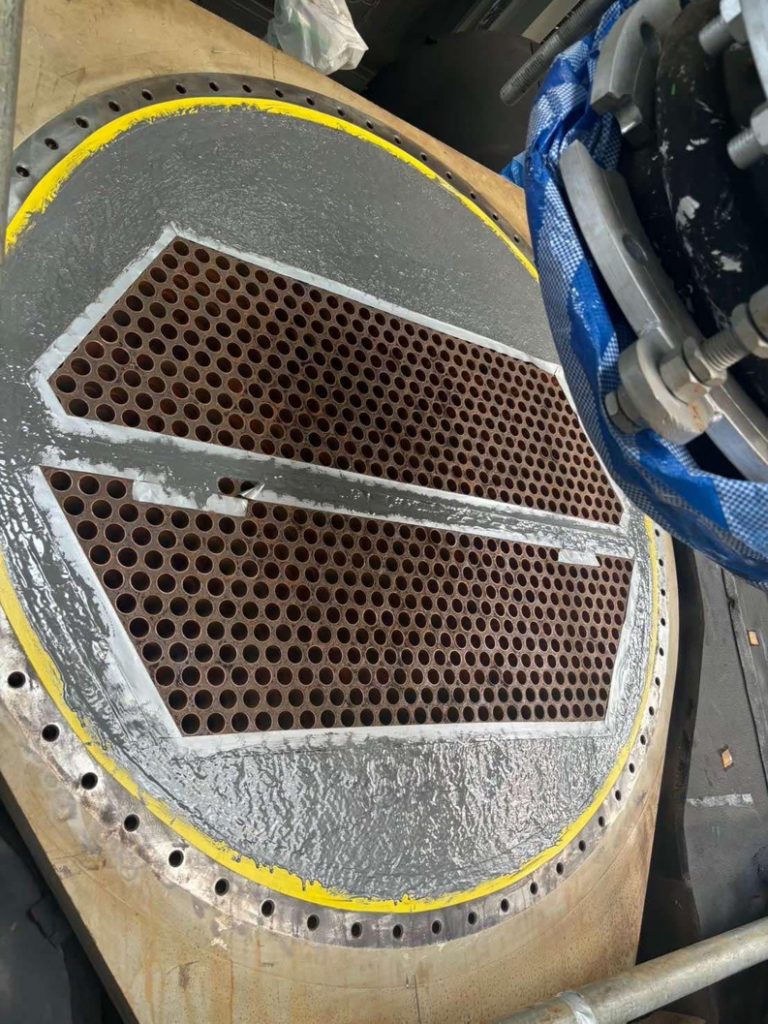

SylWrap HD Pipe Repair Bandage was then used to reinforce Superfast Aqua PW. The composite repair wrap was activated with water and applied over an area approximately 225mm, with the leak at its centre.

As SylWrap HD was wrapped and smoothed over the putty, it helped force Superfast Aqua PW further into the hole for a more effective seal. SylWrap HD set rock hard within minutes, curing to form a thick, rock hard, impact-resistant sleeve around the pipe.

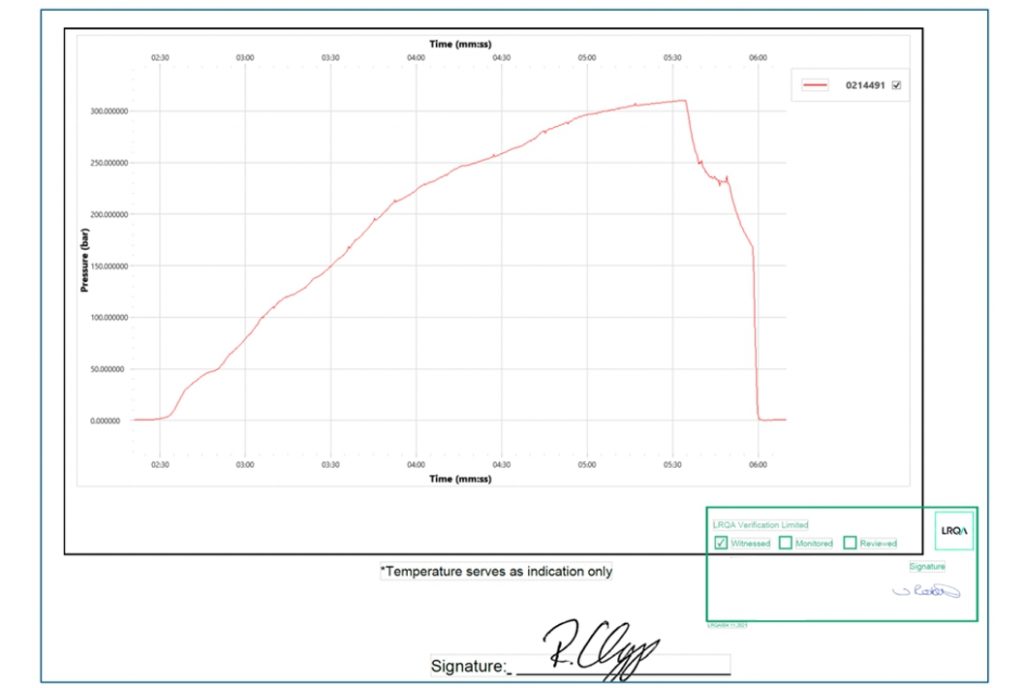

The repair was left for 24 hours to achieve maximum properties before pressure testing. This involved increasing pressure through the pipe at a steady rate for more than 30 seconds until 30 bar was reached.

After 60 seconds of the pipe being pressurised at 30 bar, the repair was inspected for any visible leakage. This test was carried out on three separate occasions.

With no leak or defect detected during any of the three pressure tests, repairs made using Superfast Epoxy Putty and SylWrap HD are qualified to meet ASME PCC-2 402-III standard.

In addition to qualifying for ASME PCC-2-402-III, Superfast Aqua PW and SylWrap HD both have WRAS approval – meaning they are certified as safe for use on pipes and fittings carrying drinking water.

For repairs to be fully ASME PCC-2 402-III compliant, installers must undergo training and certification on using Sylmasta products for leaking pipe repair. To find out more, please email sales@sylmasta.com

If you have an application you would like to enquire about, then please get in touch

Call: +44 (0)1444 831 459

Email: sales@sylmasta.com