This video was filmed at Sylmasta HQ to demonstrate how the wet surface adhesion properties of Superfast Aqua PW Epoxy Putty can be used in conjunction with a valve fitting to repair a leaking flange when pipe pressure remains on.

About this Pipe Repair Video

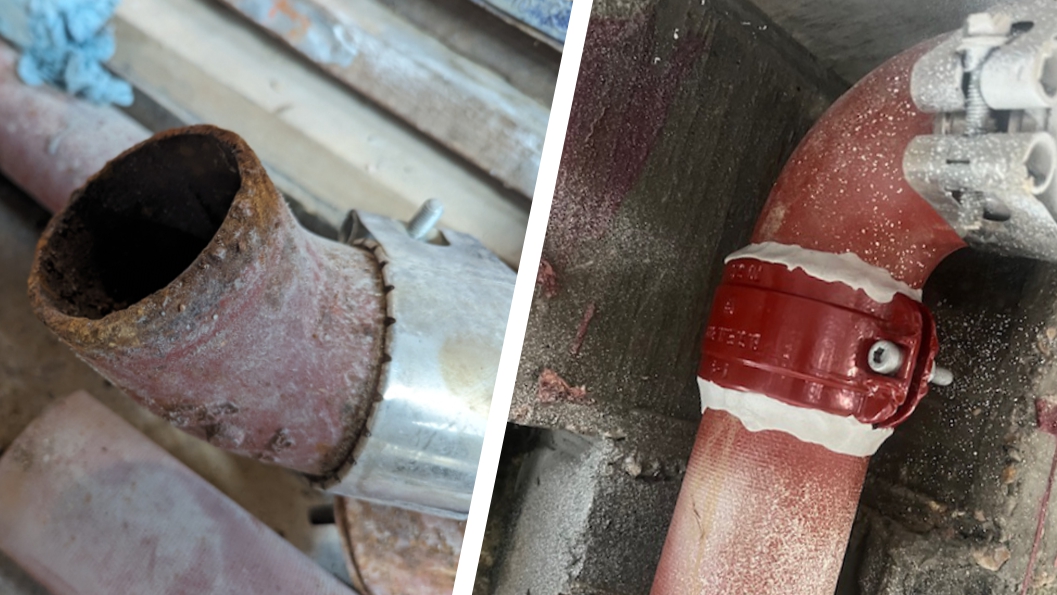

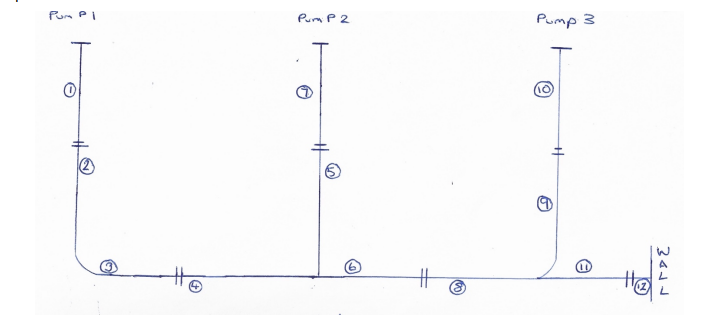

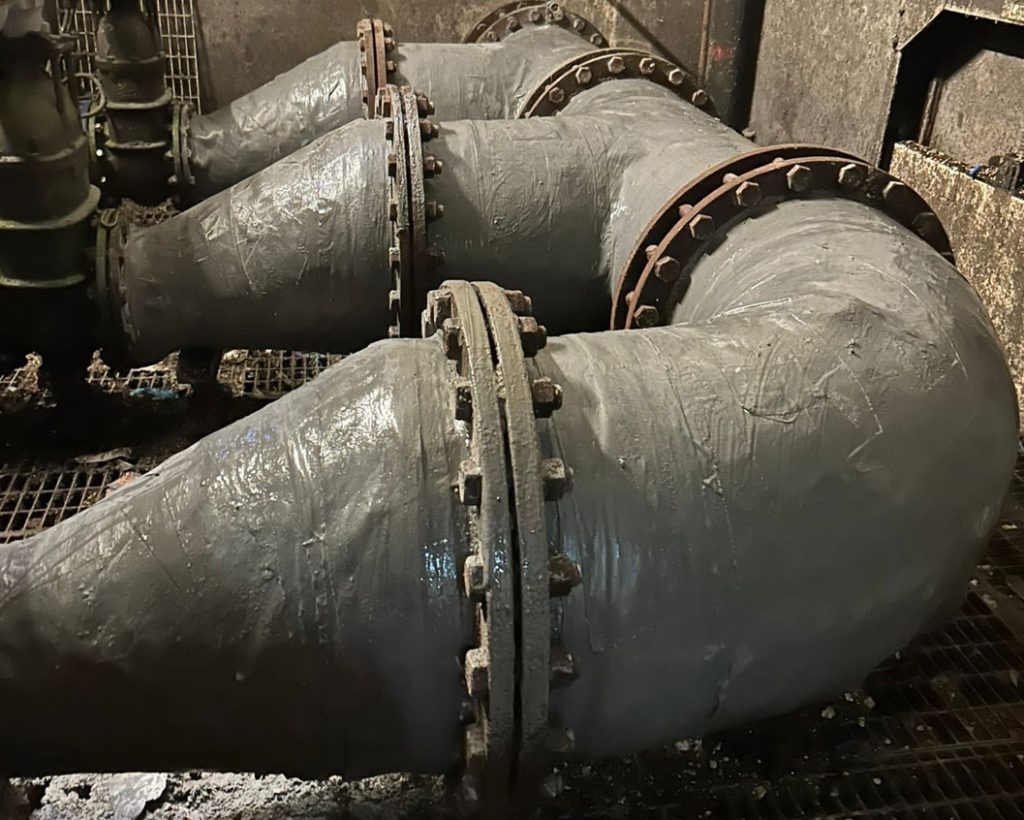

The 150mm steel pipe was leaking through a flange. Sylmasta sealed the leak whilst the pipe remained live and operating pressure was set via the test rig at 2 bar, meaning a stream of water was escaping the flange throughout.

Superfast Aqua PW Epoxy Putty was used to permanently bond a valve fitting over the leak area. This fitting channelled the leak path directly through the valve, which was then tapped off to contain pipe content.

The specialist formulation of Superfast Aqua PW offers very high wet surface and underwater adhesion. It bonds to metal, most plastics, ceramic, GRP and fibreglass in damp, wet, saltwater and freshwater conditions.

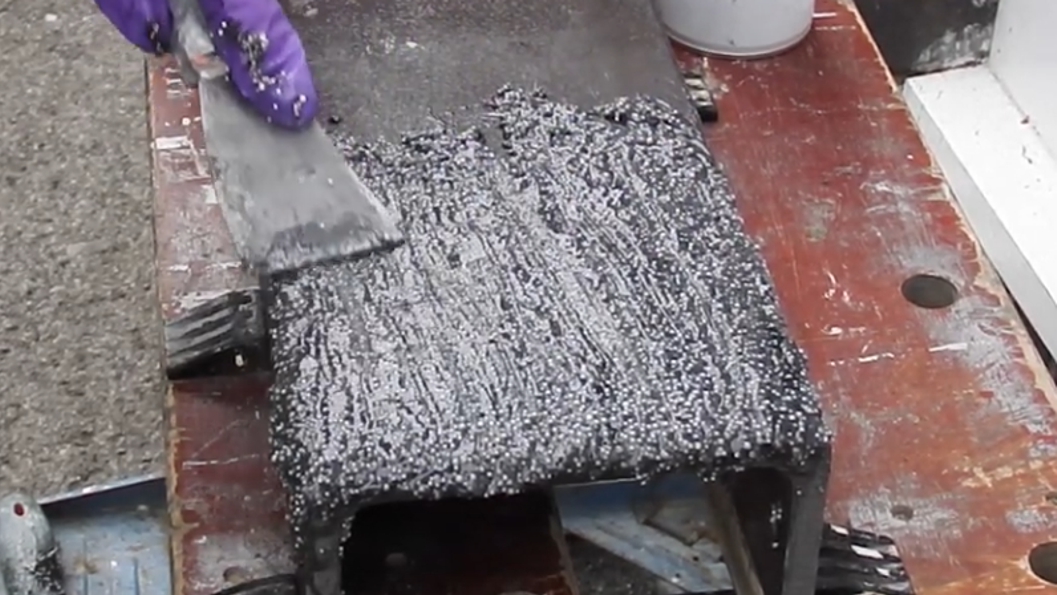

Superfast Aqua PW was kneaded by hand for three minutes until it turned a uniform white colour, indicating successful mixing. It was then attached to the bottom of the valve, before being fitted to the leak area.

The epoxy putty was pushed firmly against the pipe and flange before it hardened. Despite water continuing to saturate the pipe, Superfast Aqua PW formed a permanent bond and a watertight seal once it cured around 10 minutes after mixing began.

Once the valve had been fitted, all water leaving the pipe was directed through it. Tapping the valve ensured no more water could escape the pipe through the flange, completing the repair.

To showcase the effectiveness of a leaking pipe flange repair made with Superfast Aqua PW, Sylmasta increased pressure through the test rig from 2 bar up to 18 bar. The repair continued to hold.

The fast five minute work time of Superfast Aqua PW makes this a quick and easy repair method to seal a leaking flange when water pressure cannot be turned off.

Superfast Aqua PW has WRAS approval, meaning it is certified to British standards as safe to use on pipes and fittings carrying drinking water.

A similar repair could be made using Sylmasta AB Original Epoxy Putty. AB Original comes with a two-hour work time, making it more suitable for larger, complex repairs where longer is needed to apply the putty before curing begins.

Whilst AB Original offers the same excellent wet surface and underwater adhesion as Superfast Aqua PW, it does not have WRAS approval and so should not be used on pipes or fittings carrying drinking water.

Wet Surface Epoxy Putty

Superfast Aqua PW Epoxy Putty Stick

WRAS approved epoxy putty in a 114g stick with a fast five minute work time for making quick wet surface and underwater repairs.

Sylmasta AB Original Epoxy Putty Stick

Super-strength epoxy putty in a 200g stick with a longer two-hour work time for use in complex wet surface and underwater repairs.

If you have an application you would like to enquire about, then please get in touch

Call: +44 (0)1444 831 459

Email: sales@sylmasta.com