This repair demonstration video shows how WearShield Epoxy Paste forms a toughened protective layer reinforced with alumina beads over surfaces which is highly resistant to wear, impact and abrasion.

About this Epoxy Paste Video

WearShield is applied to machinery and equipment subjected to intense processes in highly abrasive environments.

Its dense alumina bead structure and high resin content enable WearShield to offer ultimate resistance against impact, wear, corrosion and chemical attack by forming an alumina-reinforced outer shell up to 6mm thick over parts and surfaces.

Originally formulated for the tough requirements of the South American mining industry, WearShield is now used worldwide in power plants, quarries and mills.

It protects a wide range of processing and plant equipment including ash handling systems, scrubbers, silos, chutes, mineral nozzles, agglomerator drums, trunions and metal castings.

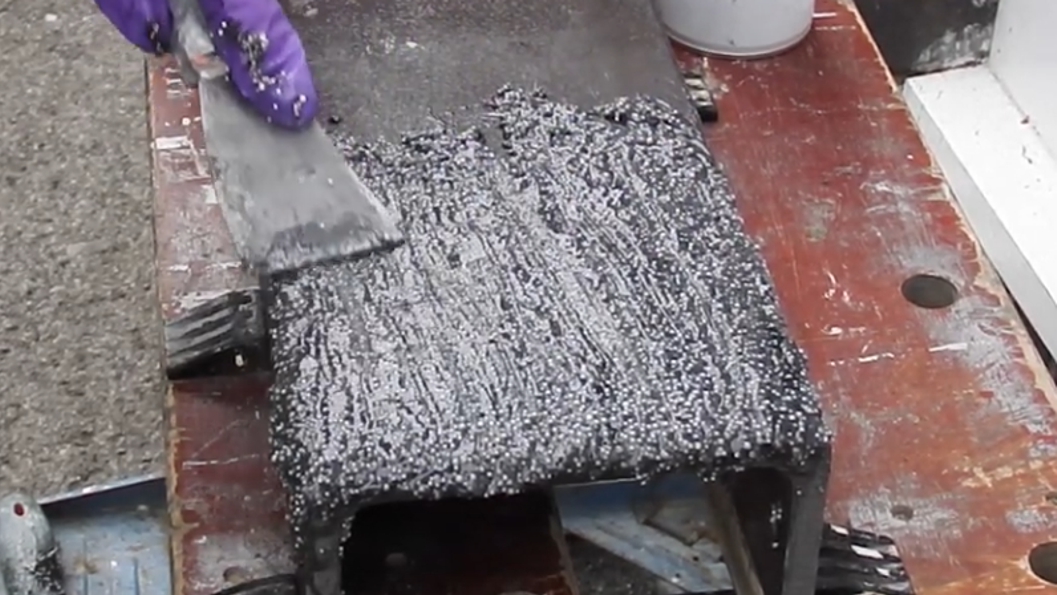

This video was filmed as part of a WearShield demonstration at Sylmasta HQ. A metal test piece underwent surface preparation, being roughened up to improve adhesion with WearShield and then cleaned.

WearShield was mixed and applied using a metal spatula. Solvent was sprayed onto the spatula to smooth off the epoxy paste after it had been coated onto the test piece. WearShield was left to cure.

Once a full cure had been achieved, the test piece was attacked with an angle grinder and hammer for abrasion and impact testing. There was no chipping or fracturing of the cured WearShield.

Lastly, the demonstration showed the benefits of top coating WearShield with Ceramic Brushable Blue Epoxy Coating to create a low-friction surface over the initial repair.

Ceramic Brushable is silicone-carbide filled, giving it an ultra-smooth finish. When used in conjunction with WearShield, it further reduces abrasion damage by limiting friction between parts. It also makes clean up more effective.

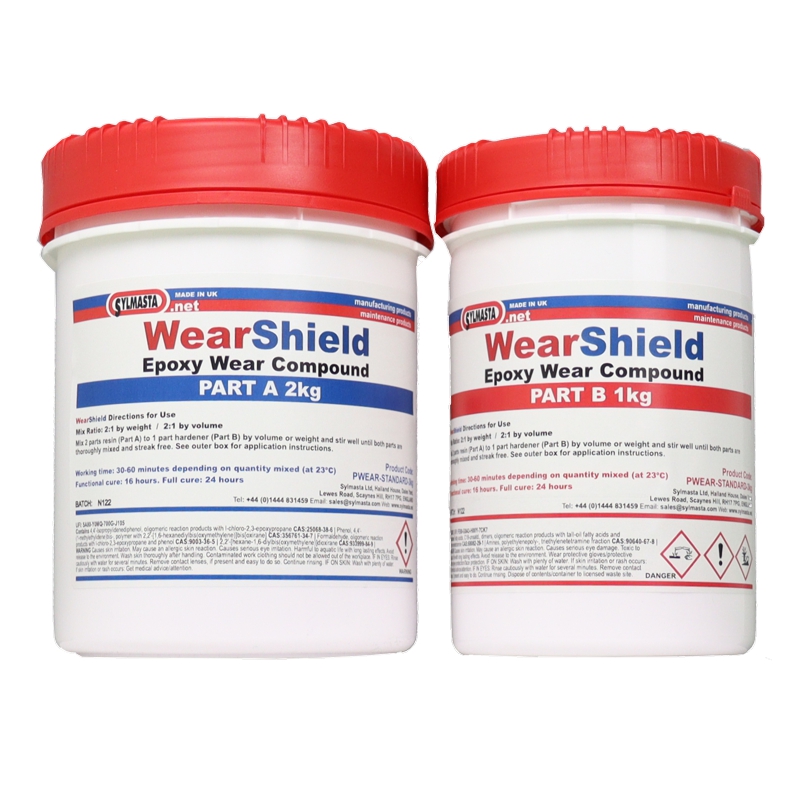

Two grades of WearShield are available. Standard comes with a work time of between 30 and 60 minutes, a functional cure of 8–12 hours. and a 24-hour full cure.

It is used at higher ambient temperatures or where large amounts of WearShield are being mixed at once, removing the threat of premature curing from the application process.

WearShield Rapid has a five-minute work time, a functional cure of 45 minutes and a full cure of three hours. It allows an abrasion resistant repair to be made quickly, minimising downtime and disruption.

WearShield Epoxy Paste

WearShield Impact Resistant Epoxy Paste

Alumina bead-filled epoxy paste which forms a toughened layer of protection against impact damage and wear

WearShield Rapid 5 Minute Epoxy Paste

Fast working version of WearShield with a three hour full cure, reducing equipment downtime

If you have an application you would like to enquire about, then please get in touch

Call: +44 (0)1444 831 459

Email: sales@sylmasta.com