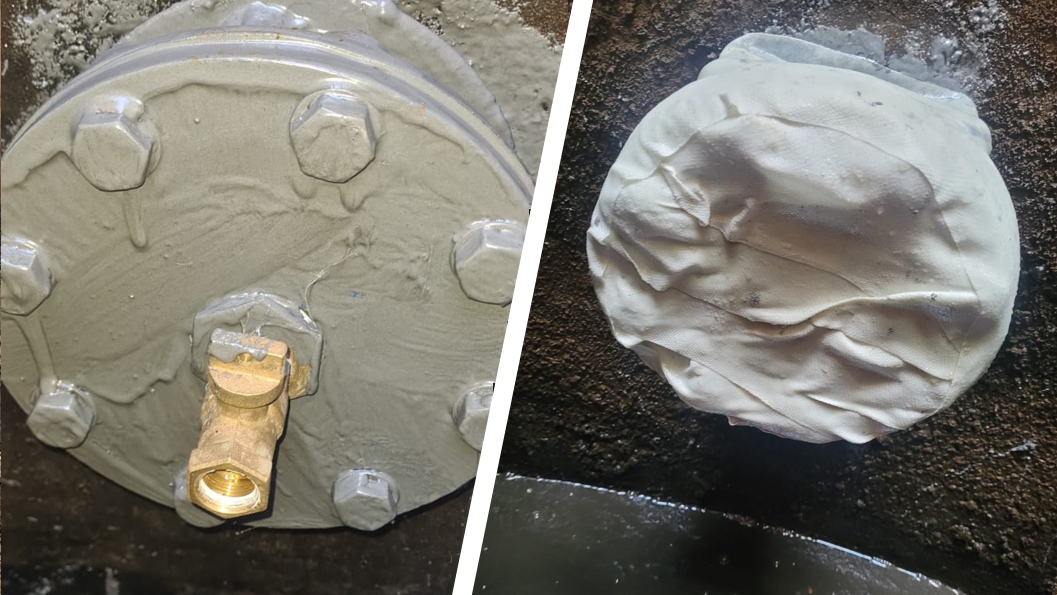

Limiting leachate from landfill – a pipe stub undergoes encapsulation to further reinforce it after capping

A landfill site in Wales encapsulates a pipe stub and flange plate after capping to protect it against corrosion and a potential future failure, ensuring a decommissioned drainage system could not release toxic leachate into the environment.

Case Study Data

Site

Landfill site

Location

South Wales

Repair Type

Encapsulation of pipe stub

Defect

Reinforcement of stub and flange plate after pipe capping

Products Used

Liquid Metal Epoxy Coating

Brushable epoxy coated onto pipes and structures to create a metallic surface which protects the original metalwork from corrosion

SylWrap HD Pipe Repair Bandage

Composite repair wrap with a water activated resin which sets in minutes to form a rock hard protective shell

Case Study PDF

Case Study Details

A series of underground drainage pumps were found to not be working at the landfill site in South Wales. Drainage is vital on landfill as it is important that rainwater does not flood, gather or pool on the site unchecked to mix with other fluids, which will often be toxic.

Rainwater that does mix with landfill to dissolve environmentally harmful substances is known as leachate. Leachate must be collected and managed properly. If it is allowed to escape into soil, groundwater or surface water, it can have an acute and chronic impact on the environment, causing serious pollution.

Rather than carrying out a complicated and expensive repair of the pumps, it was decided to decommission and replace them with an entirely new drainage system. The old system needed all pipes to be capped off at the start of the network as part of the decommissioning process.

To further reinforce after capping, the landfill site wanted to protect and encapsulate the main pipe stub and its flange plate. This would save it from corrosion and a possible failure in the future, which could lead to the release of leachate.

The stub was protruding around 300mm from a concrete wall, located towards the bottom of a chamber. There was very little space to manoeuvre within the chamber and various metal structures above the stub made access more difficult still. The flange plate itself had seven bolts and a tap which needed to be tightly sealed around.

Arch Services were appointed by the site to find a solution. Arch are a Sylmasta approved contractor for major projects and after consultation with Sylmasta technicians, a method for reinforcing the pipe stub after capping was formulated.

Liquid Metal Epoxy Coating was first used to protect the pipe stub and flange plate. Liquid Metal is a brushable epoxy which cures to form a new metallic surface when painted over pipework and other structures. It offers excellent protection against corrosion and chemicals by acting as an external shield.

Several coatings of Liquid Metal were painted all over the pipe stub and flange plate. Whilst the final coating had gelled but remained a little tacky, the stub was then encapsulated with SylWrap HD Pipe Repair Bandage.

A SYL633HD bandage was used. The resin was activated with water and the bandage wrapped around the stub and smothered over the plate. More water was applied to smooth the wrap, which cured to form a rock-hard, impact resistant covering of the stub.

Arch said after the successful completion of the application: “Given the protruding bolts and cramped application position, this was not a ‘pretty’ repair. But it absolutely did the job!” The site now had full confidence that the capped pipe would not fail in future.

If you have an application you would like to enquire about, then please get in touch

Call: +44 (0)1444 831 459

Email: sales@sylmasta.com