Sylmasta Pipe Refurbishment System ends a Mexican standoff between a wastewater treatment plant and a failing 300mm diameter steel pipeline

A wastewater treatment plant in Mexico uses a range of products from the Sylmasta Pipe Refurbishment System in a major repair and strengthening programme for a critical 300mm steel pipeline with multiple leaks.

Case Study Data

Site

Wastewater treatment plant

Location

Nuevo León, Mexico

Repair Type

Leak repair and pipe reinforcement

Defect

300mm steel pipeline failing in multiple points along its length

Products Used

Wrap & Seal Pipe Burst Tape

Self-amalgamating tape repairs live leaks by forming a solid rubber band containing pipe content

Superfast Aqua PW Epoxy Putty

Epoxy putty with specialist formulation for bonding to wet surfaces used for sealing leaking pipes

SylWrap HD Pipe Repair Bandage

Composite repair bandage sets rock hard when wrapped around pipes to form a protective outer sleeve

Liquid Metal Epoxy Coating

Brushable epoxy painted onto pipework to create a new, metallic layer protecting and strengthening the original substrate

Case Study PDF

Case Study Details

Ageing infrastructure, a lack of investment and rapid population growth has caused a severe wastewater crisis in Mexico stretching back decades – particularly in the north-west of the country along the border with the United States.

Most notorious is the Tijuana River Sewage Crisis, a pollution incident ongoing over many years which has allowed billions of litres of sewage to flow from Mexico through California and into the Pacific Ocean.

The maintenance and upkeep of wastewater facilities in Mexico has therefore understandably come in for heavy scrutiny and criticism both domestically and internationally.

Which is why the plant in the north-eastern state of Nuevo León wanted to put into place a leak repair and pipe strengthening programme focussed on a critical 300mm steel pipeline showing signs of failure.

There were multiple areas of concern, all requiring different solutions. The plant therefore selected a range of products from the Sylmasta Pipe Refurbishment System for the programme.

The Sylmasta Pipe Refurbishment System is a four-stage process designed to repair, refurbish, strengthen and protect pipelines in any given scenario. It goes beyond just leak sealing, providing complex solutions to extend the lifespan of critical infrastructure.

One area of the pipe which could not be isolated was weeping around an elbow. Wrap & Seal Pipe Burst Tape was selected for use on this section because of its live leak repair capabilities.

Wrap & Seal is a self-amalgamating repair tape which stretches by three times its length. As it was wrapped around the elbow, it fused to form a solid rubber band exerting pressure over the leak to contain pipe content.

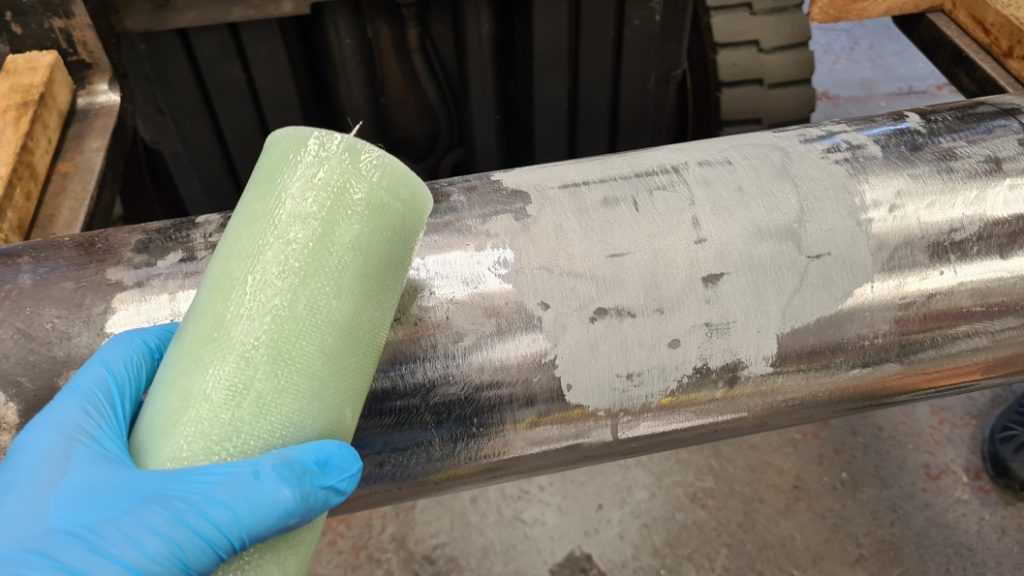

The tape was then overwrapped with SylWrap HD Pipe Repair Bandage. SylWrap HD is a water-activated composite wrap with a fast acting resin which sets rock hard in minutes.

SylWrap HD was wrapped and smoothed around the pipe, creating an impact resistant outer sleeve protecting both the elbow and the Wrap & Seal repair.

A more challenging leak area was located on a tee joint, where Wrap & Seal could not be applied as effective wrapping was impossible. The plant instead used Superfast Aqua PW Epoxy Putty Stick.

Superfast Aqua PW is a fast-working putty with a specialist formulation for high underwater adhesion. The putty was mixed by hand and forced firmly onto pipe.

It easily bonded despite the wet surface, curing within 20 minutes to form a hardened, steel-like material encompassing and sealing all around the joint.

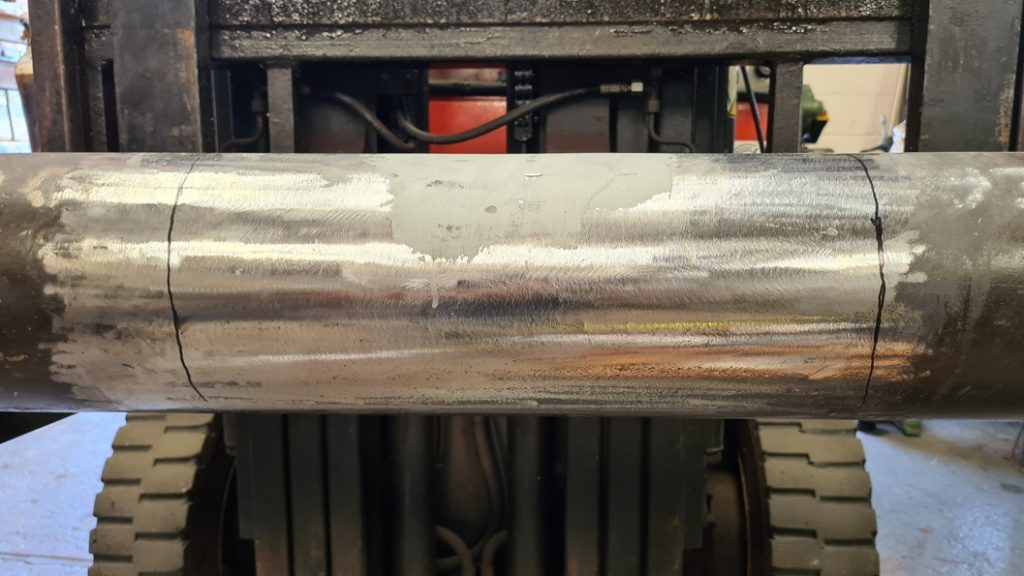

One all leaks had been attended to, the final stage of the wastewater treatment plant pipe repair involved painting all weakened sections with Liquid Metal Epoxy Coating.

Liquid Metal was brush applied across areas of the pipe which had been corroded and degraded over time, including the tee-joint sealed earlier in the programme.

The epoxy coating cured to form a smooth, metallic, hard-wearing outer shield protecting the original substrate against corrosion or chemical attack.

In the event of the pipeline being breached from inside, the impermeable membrane formed around the pipe by Liquid Metal would also contain pipe content to prevent future leaks.

By the end of the programme, the wastewater treatment plant had a fully refurbished pipeline with all existing leaks sealed and capable of withstanding future problems.

The Sylmasta Pipe Refurbishment System has since been used by other facilities in Mexico as a cost-effective and straightforward way to strengthen pipelines as the country makes positive strides to improving its wastewater situation.

If you have an application you would like to enquire about, then please get in touch

Call: +44 (0)1444 831 459

Email: sales@sylmasta.com