Getting a grip in Chile – Liquid Metal combined with silicon carbide grit lay new anti slip flooring at PepsiCo Plant

The PepsiCo production plant in Chile use Liquid Metal Epoxy Coating and silicon carbide grit as a cost effective method for installing new and replacement anti slip flooring in 12 different areas across the site.

Case Study Data

Site

PepsiCo production plant

Location

Chile

Repair Type

Creation of anti slip surfaces on plant flooring

Products Used

Liquid Metal Epoxy Coating

Epoxy coating brush applied across floors to bond silicon carbide grit for the creation of anti slip surfaces

Case Study PDF

Case Study Details

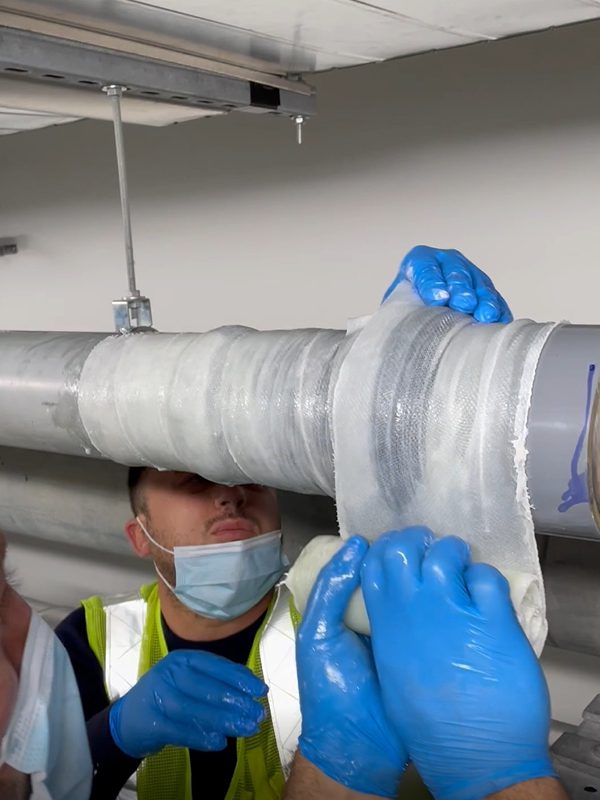

PepsiCo needed to lay anti slip flooring in 12 different sections across their production plant in Chile, both to replace existing surfaces which had lost their effectiveness and create new safe areas.

The floor surfaces requiring treatment included the tiled floor of a warehouse, concrete corridors, a metal ramp, stainless steel ladders and staircases, and an open lift used to transport goods between floors.

Because of the large scale of the application, the maintenance team wanted to find the most cost-effective and convenient method for laying anti slip surfaces possible.

The way they decided to do this was by using an epoxy coating capable of bonding silicon carbide grit to each of the different surface materials requiring anti slip treatment.

Sylmasta recommended the use of Liquid Metal Epoxy Coating. Liquid Metal would adhere to all the surfaces throughout the plant, offering high bond strength between the floor and the silicon carbide grit.

A long gel time allows for more Liquid Metal to be mixed at once and carefully painted onto a substrate without worry of the coating curing off before application is completed.

Masking tape was used to mark out where the anti slip strips were required and the exposed surface painted with Liquid Metal. Whist the epoxy coating remained tacky, silicon carbide grit was sprinkled over the top. The masking tape was then removed.

Once the Liquid Metal had fully cured, it permanently bonded the grit with the floor to leave behind a new anti slip surface.

This method was used across all 12 areas of the plant and was successful no matter whether the surface was metal, concrete or tile. The application was completed within 24 hours of the final area being coated with Liquid Metal.

The ease and speed of the installation has since led PepsiCo to use Liquid Metal and silicon carbide grit for laying anti slip surfaces at other plants and even inside their delivery vans.

If you have an application you would like to enquire about, then please get in touch

Call: +44 (0)1444 831 459

Email: sales@sylmasta.com