Customised coloured putty restoration puts Clan MacGregor Dalmally Burial Stones back on display for first time in 400 years

Sylmasta manufacture a specialist version of AB Original Epoxy Putty colour-matched to RAL 7037, helping the Clan MacGregor Dalmally Burial Stones go on display inside Glenorchy Parish Church following restoration for the first time in 400 years.

Case Study Data

Site

Church

Location

Scotland

Repair Type

Burial stones restoration

Defect

Pieces missing from base of burial stones

Products Used

Sylmasta AB Original Epoxy Putty

Super-strength epoxy putty which bonds to all materials, filling in and rebuilding large areas of damage

Case Study PDF

Case Study Details

In 1996, the Clan Gregor Society discovered that seven burial stones sunk into the ground in the churchyard of the Glenorchy Parish Church at Dalmally, near Loch Awe, Scotland, belonged to the ancient chiefs of Clan MacGregor.

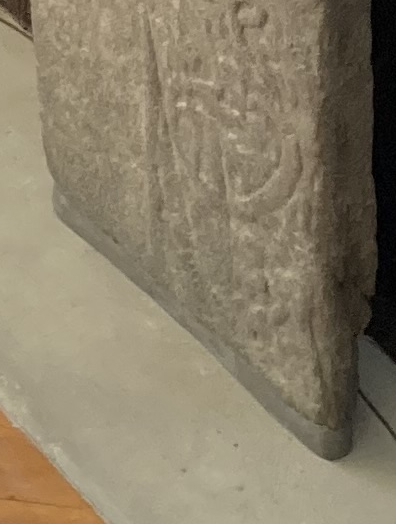

The stones were originally placed around the high altar of the church to mark the burial spots of clan chiefs. The oldest belonged to John Macgregor of Glenurquay, who was buried on the north side of the High Altar of the original church in 1390. The most modern came from 1528.

Clan MacGregor fell from favour in the early 1600s. The name was banned by King James VI of Scotland following a particularly bloody bout of violence. It was one of his last acts before travelling to London to take up the British crown following the death of Elizabeth I.

The attempted erasure of Clan MacGregor by King James left them with no castle to call their own and the destruction of almost all their historical objects. The Dalmally Stones are therefore one of the few surviving examples of medieval heritage relating to the ancient Clan, whose proscription lasted 170 years.

It is believed the burial stones were removed from the high altar in 1615 when the church was rebuilt as part of The Reformation. They were taken outside and used to cover other grave plots in the churchyard.

By the time the Clan Gregor Society realised their importance, the burial stones had been on the ground for more than 350 years. Erosion, dirt ingress and other forms of damage as the stones sunk over the course of three centuries had left them in desperate need of conservation.

And so the Clan Gregor Society put together an ambitions plan to raise, restore and then return the Dalmally Stones to display inside the church.

It would take another 26 years until 2022 for the society to secure permissions from religious bodies, heritage societies, local and national government, as well as raising enough funds to make the project a reality.

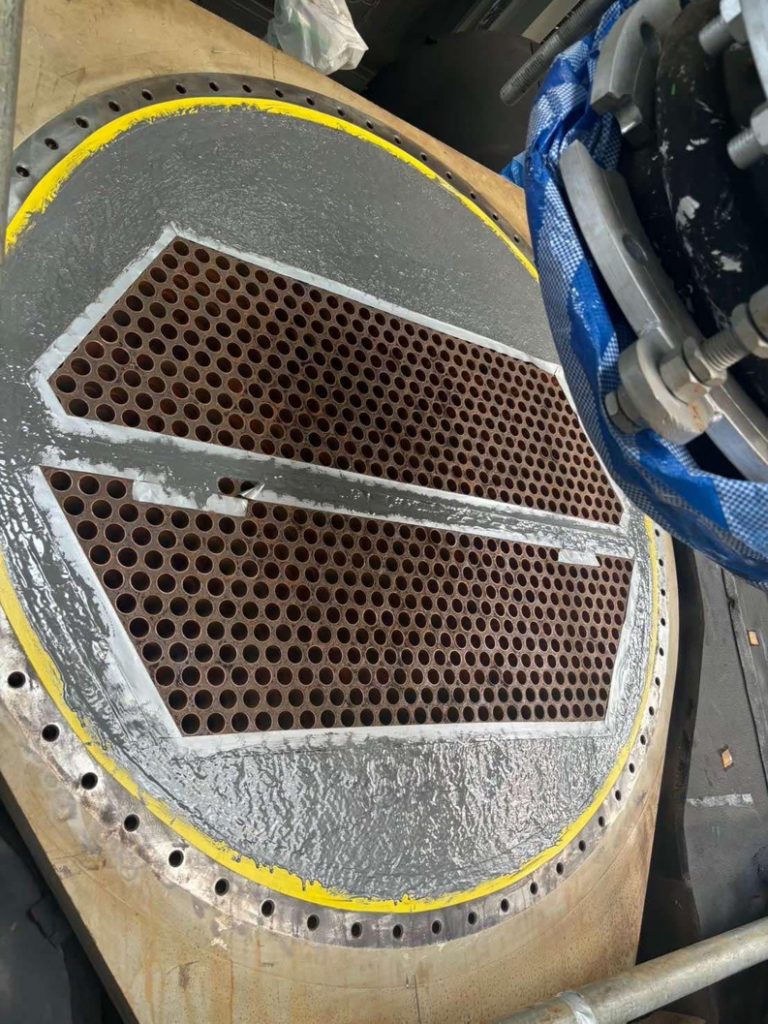

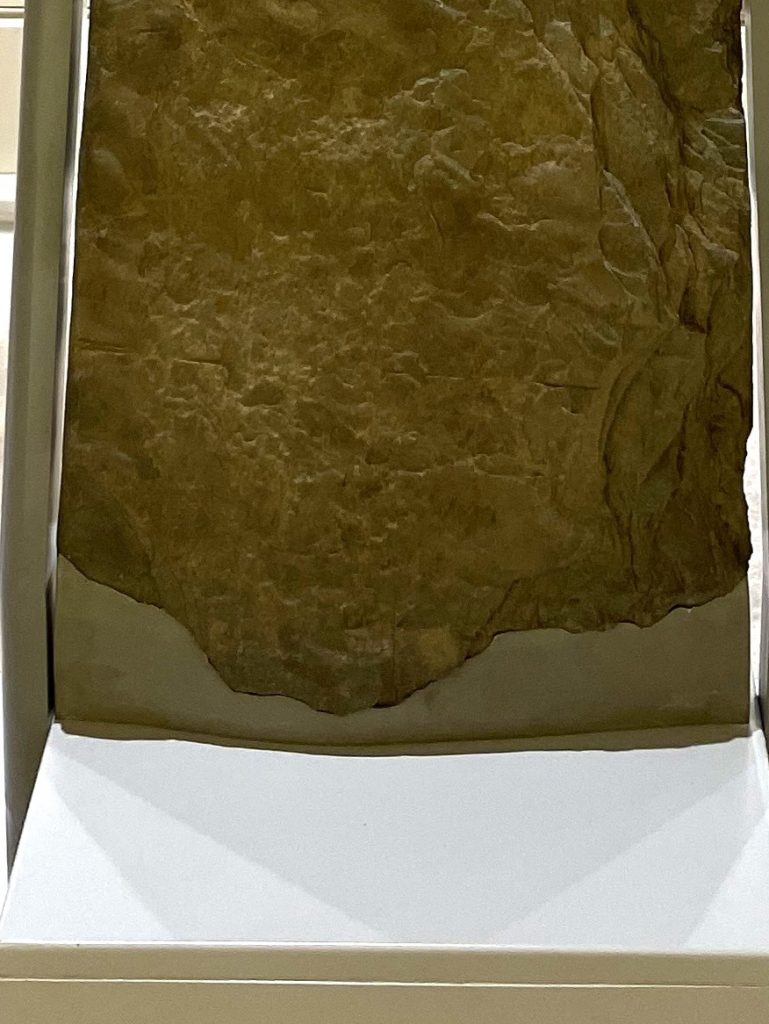

After that time-consuming process was completed, Graciella Ainsworth Sculpture Conservation were commissioned to restore the stones. One challenge came from huge chunks missing from the base of the stones, leaving them unable to stand on display.

Sylmasta formulated a specialist version of AB Original Epoxy Putty colour-matched to RAL 7307, which the team at Graciela Ainsworth believed to be the closest match to the stones after they underwent thorough cleaning during the restoration process.

AB Original was then used to create a flat, bottom edge on each stone, so that they could be placed standing inside the church. 30kg of AB Original was sent to Scotland. The putty was kneaded by hand and then applied to rebuild the bottom of each stone.

The two-hour work time of AB Original allowed for careful, precise application without the threat of premature curing. Once set, AB Original formed a ceramic-like material similar to the original stonework in both texture and colour.

After Graciella Ainsworth had completed their restoration of the Dalmally Stones, they were fixed in place inside the church for the first time in 400 years. A dedication ceremony was held as part of a weeklong Clan Gregor celebration, attended by society members who travelled to Scotland from around the world.

The beautiful carvings of knights and delicate patterns decorating the stones – which are considered fine examples of the Loch Awe School – can now be fully appreciated and are preserved for future generations to admire.

AB Original has since been used by Graciella Ainsworth in similar applications, including creating supporting shoes for a series of display pieces at the New Perth Museum.

Sylmasta’s investment in the latest epoxy putty stick manufacturing technology at their site in the United Kingdom means other colour-customised putties can be quickly and easily made for future conservation and restoration projects depending on client requirements.

If you have an application you would like to enquire about, then please get in touch

Call: +44 (0)1444 831 459

Email: sales@sylmasta.com