Sharing a window on how to seamlessly repair and restore a rotted bay sash frame

A bay sash window frame which had rotted after only eight years due to severe weathering and poor preparation by the installer undergoes repair and restoration by the homeowner using Sylmasta AB Original Epoxy Putty.

Case Study Data

Site

Domestic property

Location

England

Repair Type

Wood repair

Defect

Heavily rotted bay sash window

Products Used

CA3 Penetrating Superglue

Very low viscosity cyanoacrylate superglue stabilises wood by wicking deep into soft damaged fibres and turning them rock hard

Sylmasta AB Original Epoxy Putty

Epoxy putty which is easy to shape and mould when used as a filler to rebuild missing sections of damaged wood

Case Study PDF

Case Study Details

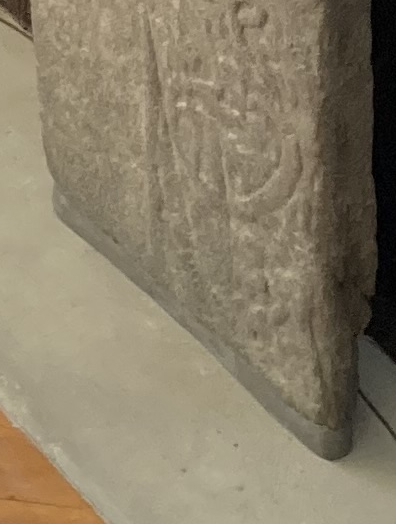

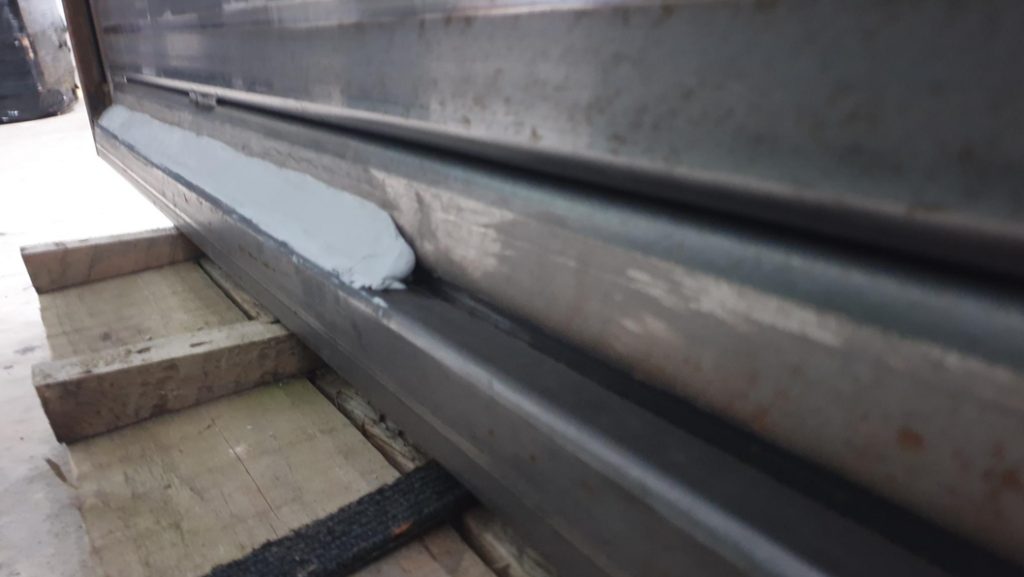

When installed eight years earlier, the bay sash window was brand new. Thanks to severe weathering and poor preparation by the installer, one sharp corner had become heavily rotted in just eight years.

The rot first softened the wood, then caused cracks to appear before chunks of timber eventually fell away. It left very obvious and unsightly damage visible to all visitors and passers-by.

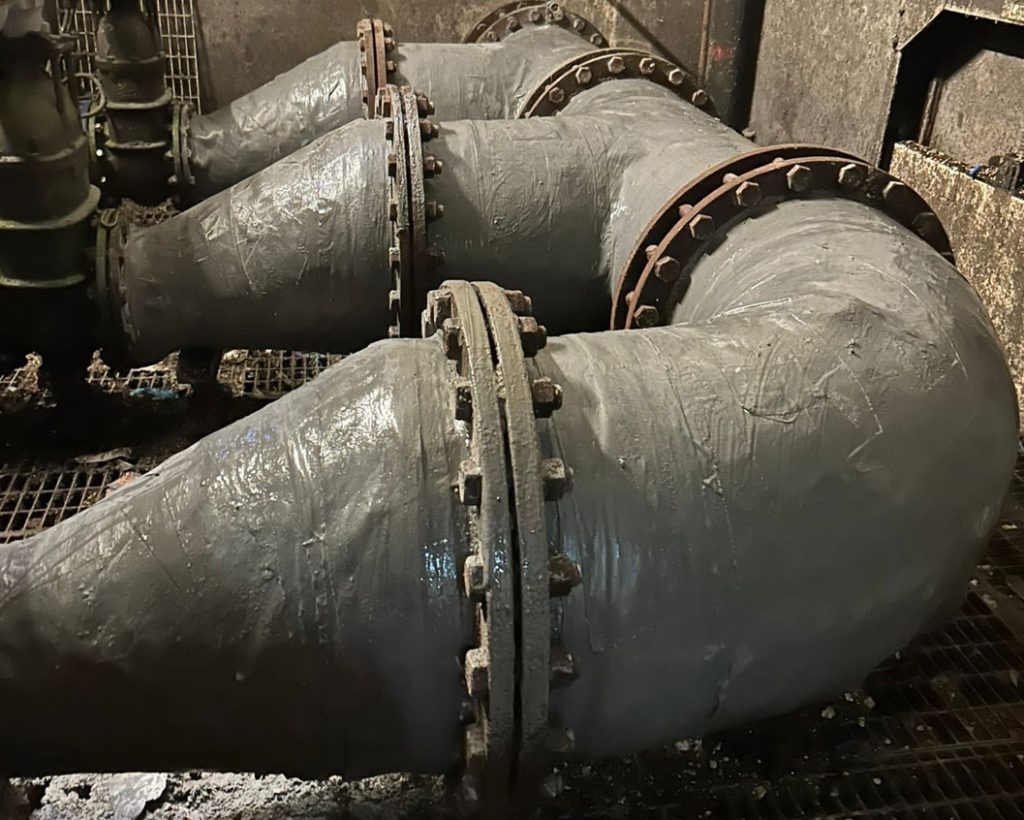

Wanting to repair the bay sash window, the homeowner contacted Sylmasta for advice. A restoration plan was formulated involving cleaning, stabilising and then rebuilding the damaged corner.

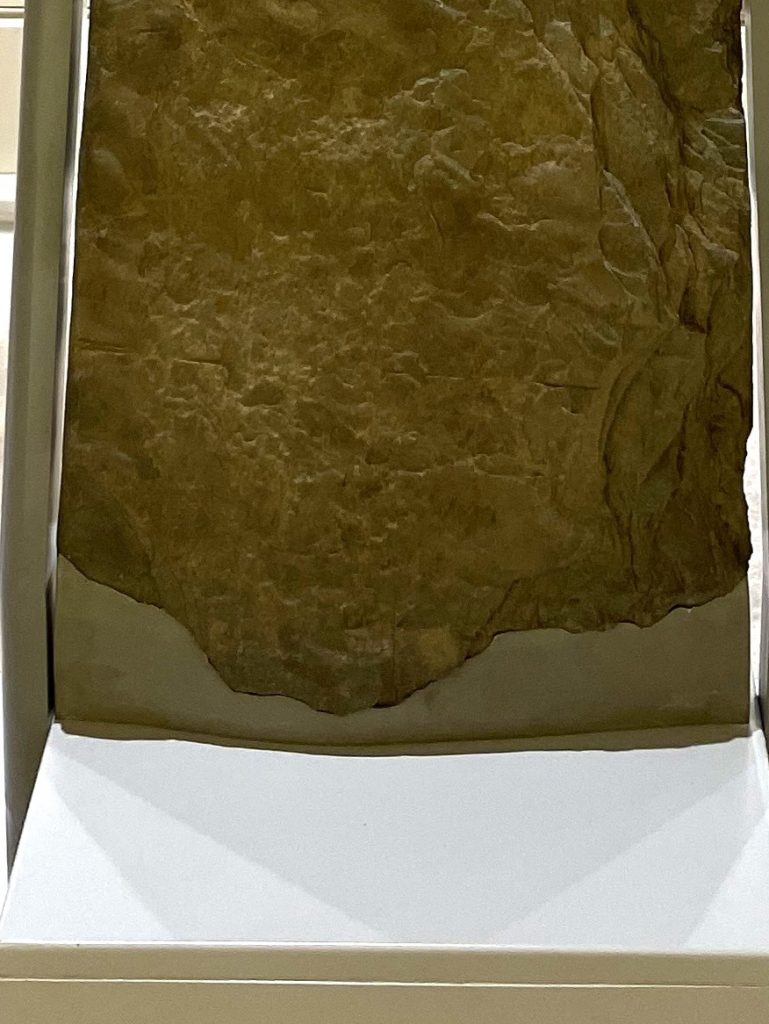

All loose rotted timber was removed from the bay sash window frame as the first stage of repair. Any remaining fragile wood was then stabilised using CAE3 Penetrating Cyanoacrylate Superglue.

The extreme low viscosity of CAE3 makes it as thin as water. This allows CAE3 to penetrate porous surfaces, wick into cracks and flow easily into small and hard-to-access areas.

When CAE3 was applied to the bay sash window corner, it permeated deep into the damaged fibres of the frame. It cured rapidly to turn all wood which had been left soft and fragile by rot into a rock-hard material ready to be rebuilt with epoxy putty.

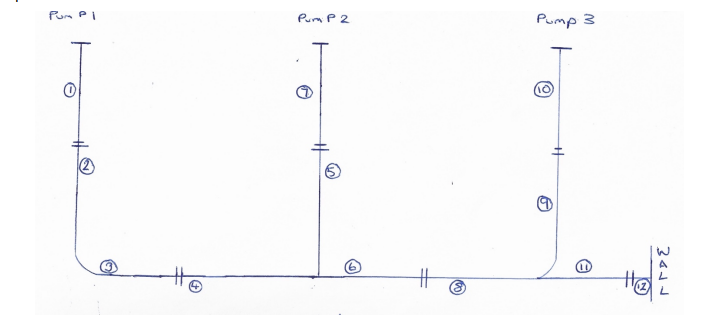

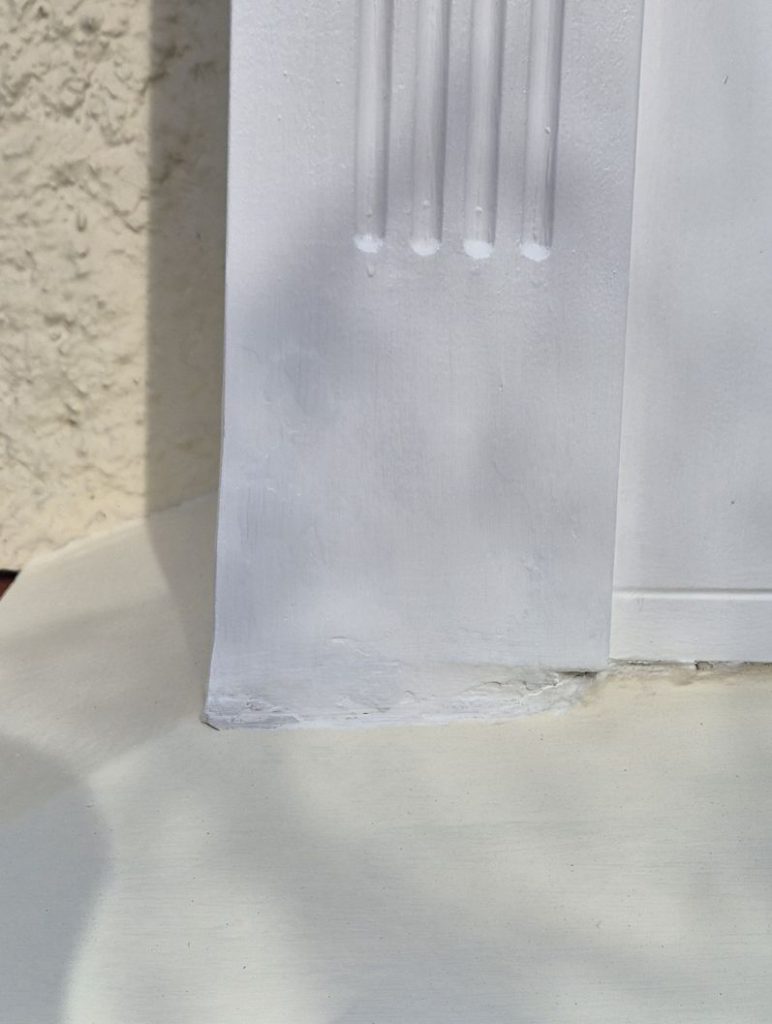

It was decided to use Sylmasta AB Original Epoxy Putty. AB Original was chosen for its two-hour work time, allowing the homeowner to mix, shape and apply the putty carefully without the worry of it curing off quickly.

AB Original was kneaded by hand and applied direct to the frame. It easily adhered to the stabilised wood. Enough putty was added until all the missing wood was filled and replaced, leaving the damaged corner rebuilt.

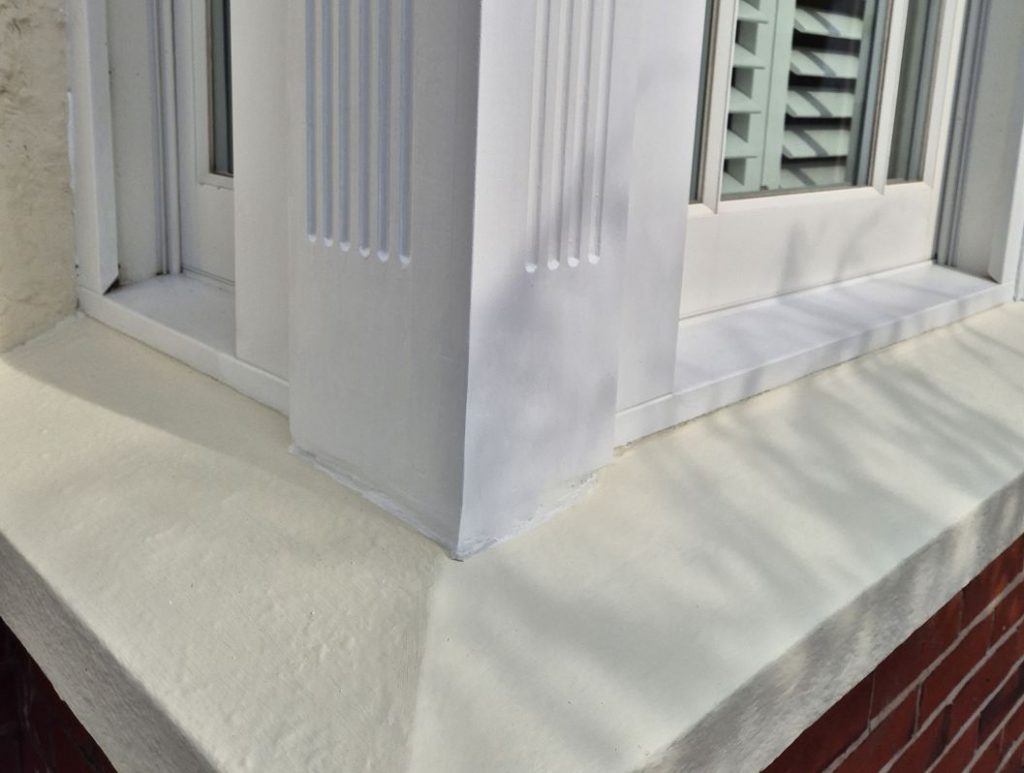

Before curing, the putty was smoothed off using a metal spreader and a little water. Once it had fully hardened, it was lightly sanded down and then painted the same white colour as the sash window for a seamless restoration.

The homeowner had never handled epoxy putty before making the repair. They said afterwards they liked how straightforward an AB Original Stick was to use, simply by cutting off the amount of putty required and mixing by hand.

They also appreciated not having to rush the putty application because of the longer work time, and that AB Original did not sag or lose shape as it was applied to the bay sash window corner.

If you have an application you would like to enquire about, then please get in touch

Call: +44 (0)1444 831 459

Email: sales@sylmasta.com