All aboard for the SylWrap HD conduit pipe repair which helped keep a train on the tracks

Aluminium conduit pipe carrying cables underneath a train undergoes repair and reinforcement using SylWrap HD Pipe Repair Bandage after stones, ballast and other debris flying up from the railway track bed caused impact damage.

Case Study Data

Site

Railway network

Location

United Kingdom

Repair Type

Conduit pipe repair

Defect

Damaged aluminium conduit pipe carrying electrical cables underneath train

Products Used

SylWrap HD Pipe Repair Bandage

Composite repair wrap with water activated resin encompasses pipes with a rock-hard, impact resistant outer sleeve

Case Study PDF

Case Study Details

The railway network in some areas of the United Kingdom operates a third rail system. Rather than electricity coming from overhead cables, it is supplied to the train from a powered conductor rail on the track bed.

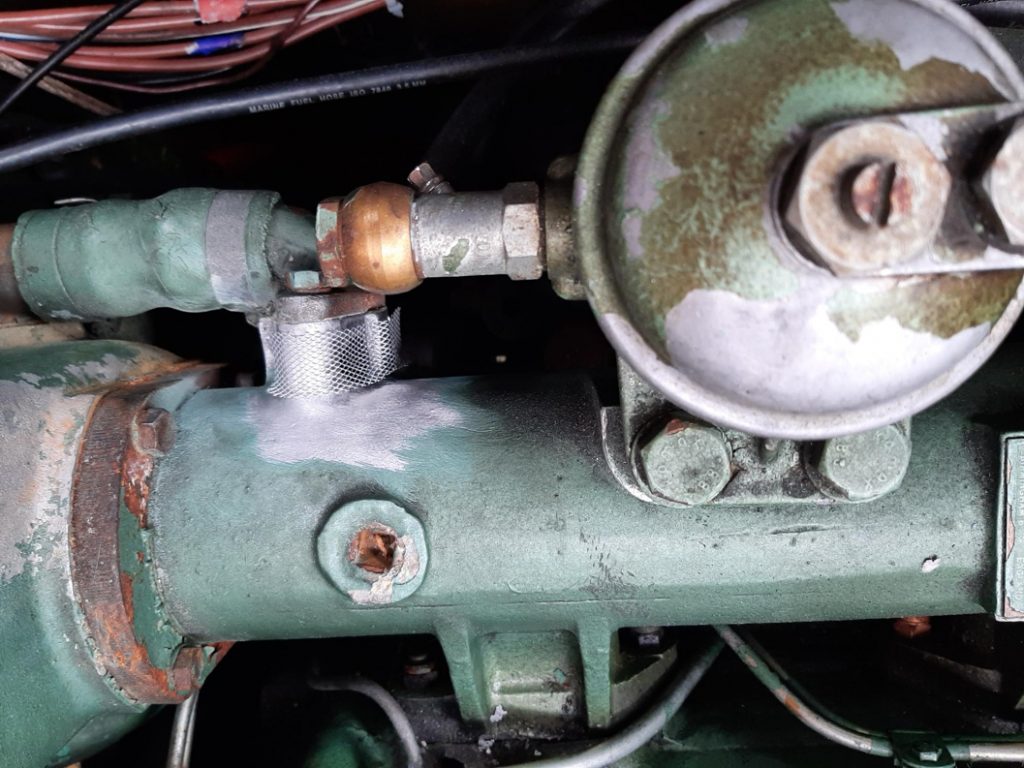

Metal blocks – known as shoegears – underneath the train make contact with the third rail. They take electricity from it, which then flows into the power system of the train through a series of cables also attached underneath.

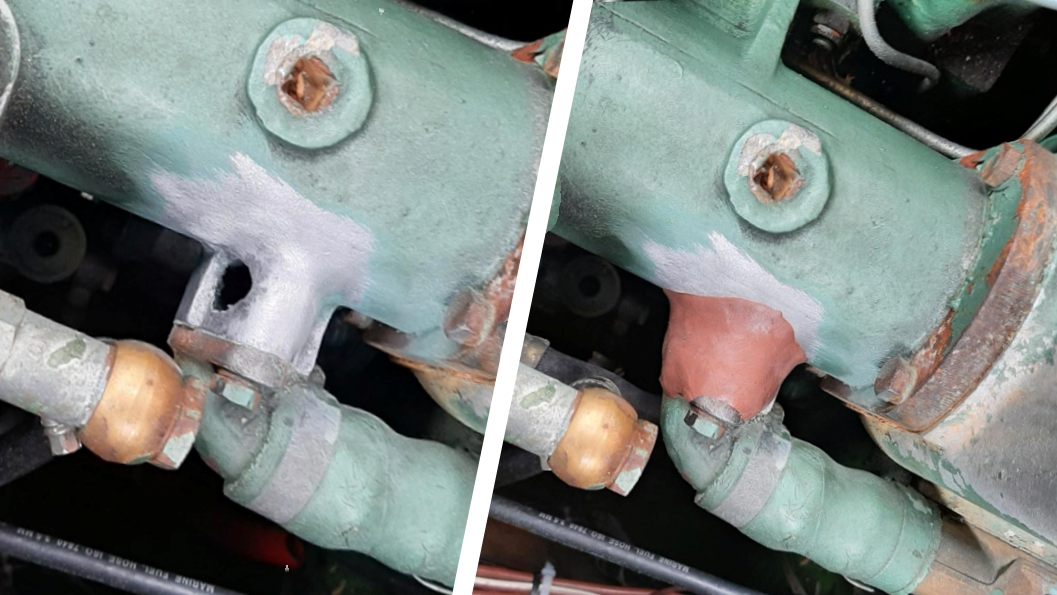

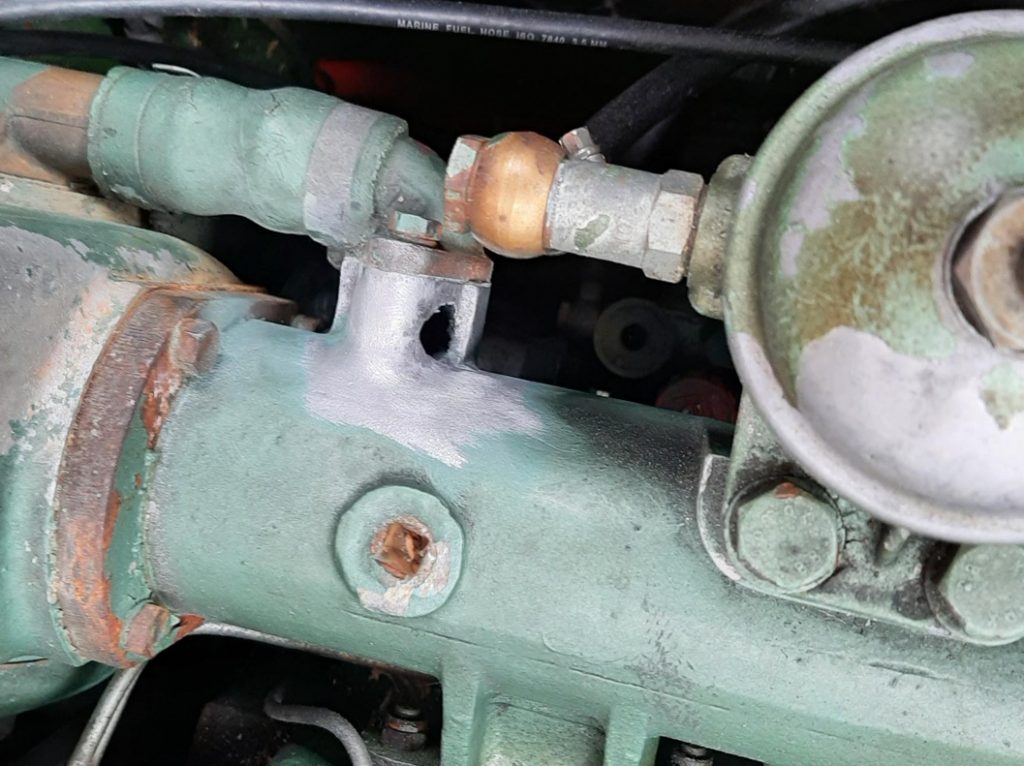

Sylmasta were approached by a rail operator whose under-train cables were housed in aluminium conduit pipe. When the train hit high speeds on sections of the railway where the ballast track bed was loose, stones were becoming airborne and damaging the pipe.

Over time, this repeated impact caused tears to appear in the aluminium conduit. The cables inside were subsequently left dangerously exposed and at risk of being damaged themselves.

The rail operator was looking to repair the holes in the aluminium and provide better protection from future damage, without having to take the train out of service for a long period of time to replace the entire conduit pipe.

Sylmasta recommended wrapping SylWrap HD Pipe Repair Bandage along the conduit pipe to seal the tears and provide the aluminium with a robust outer casing.

Unlike other suppliers of moisture cured composite wraps who import from Asia or North America, Sylmasta manufacture the SylWrap range of pipe repair bandages at their site in the UK.

It was therefore possible to produce a customised SylWrap HD based on the rail operator’s requirements. Black dye was used, colouring the bandages black instead of the standard white to better disguise the repair.

Additional inhibitors were also added to make the bandages more fire retardant, enabling them to comply with stringent regulations governing materials used on the railway.

Rail workers accessed the bottom of the train and applied eight layers of SylWrap HD to all areas of the conduit pipe requiring repair and protection. The fast-working resin set within minutes, curing to form a rock-hard shell offering total resistance to impact damage.

When stones, ballast and other materials now flew up from the track bed, they would be repelled by SylWrap HD rather than coming into contact with the aluminium conduit pipe.

The repair was completed inside a day and with a huge cost saving compared to replacing the conduit pipe. The train returned to service with the rail operator confident there would be no further damage.

If you have an application you would like to enquire about, then please get in touch

Call: +44 (0)1444 831 459

Email: sales@sylmasta.com