River repair runs smooth – a crack in an underwater wall between a river and a trout farm is permanently sealed

The Environment Agency repair an underwater wall discovered to be cracked when a system monitoring how much water was being taken from a Yorkshire river by a local trout farm began returning inaccurate readings.

Case Study Data

Site

Sluice between river and trout farm

Location

Yorkshire, United Kingdom

Repair Type

Crack repair

Defect

700mm long crack in underwater wall

Products Used

Sylmasta AB Original Epoxy Putty

Super-strength epoxy putty effective underwater used to permanently seal holes and cracks

Case Study PDF

Case Study Details

Trout farms in North Yorkshire are allowed to draw a limited amount of water from local rivers and streams. Extraction is normally controlled by a sluice connecting a farm to a river, which also enables the Environment Agency to monitor water levels to ensure no more than the permitted amount is taken.

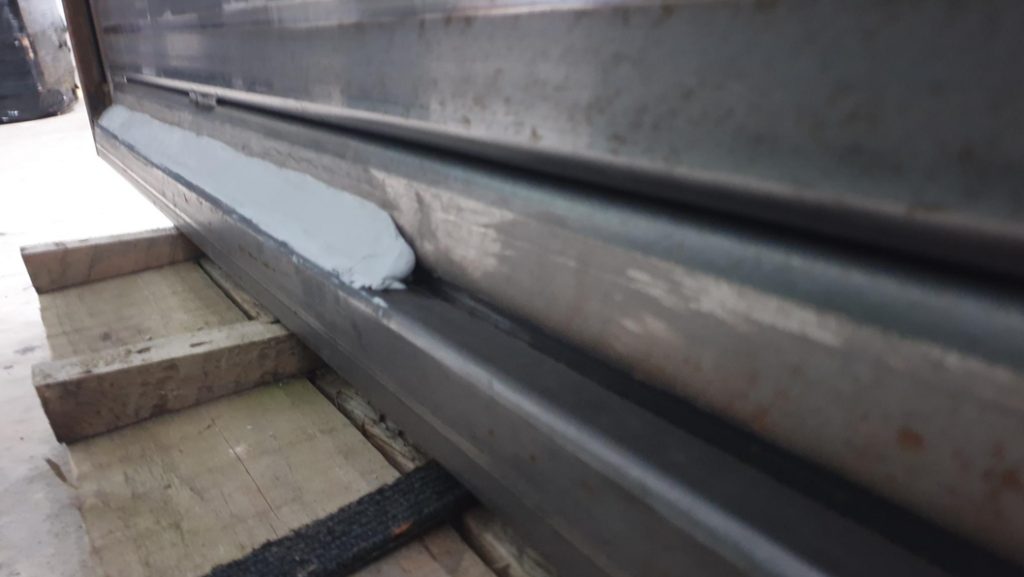

Anomalies with data from one farm alerted the Environment Agency to a potential issue, initially believed to be with the sluice or the monitoring equipment. An inspection revealed that the problem was actually a 700mm long crack in a wall next to the sluice. The crack widened into a sizable hole as it reached the riverbed.

Water from the river was now escaping through the crack and into the trout farm, making readings of the flow through the sluice completely inaccurate. The wall needed to be sealed to prevent water loss and ensure that the true level of water being taken by the farm could be recorded.

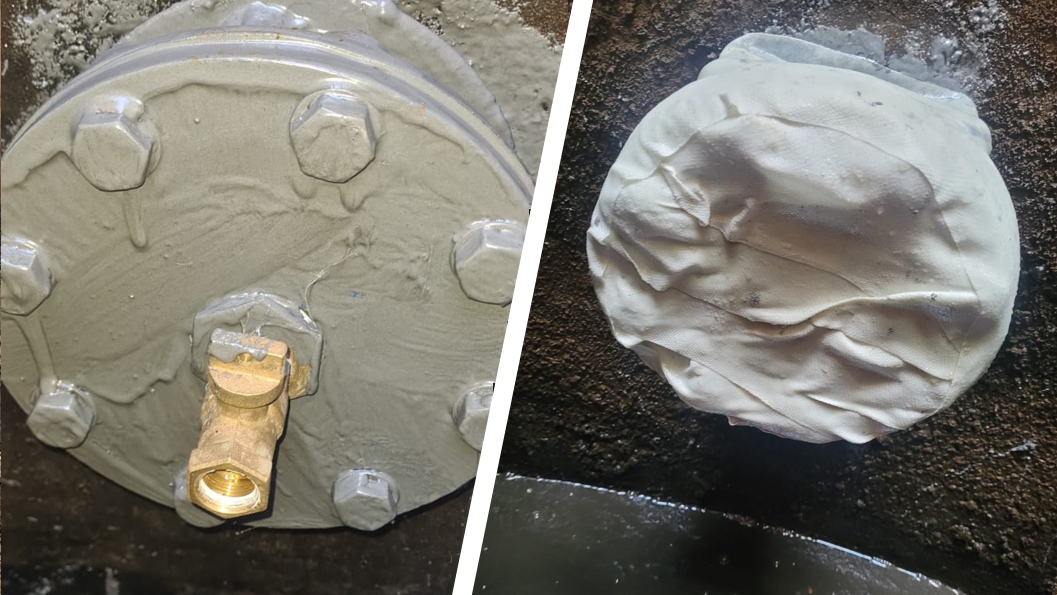

Sylmasta AB Original Epoxy Putty provided the ideal solution. AB Original is a ceramic-filled, high strength epoxy putty which cures underwater. It comes with a two hour work time, meaning that significant amounts of putty could be mixed to fill the crack without the threat of premature curing.

An engineer from the Environment Agency attended the site with a large quantity of AB Original. Part A and Part B were kneaded in dry conditions. Once the putty had turned a uniform white colour and whilst it still remained soft, it was pushed into the crack.

The application began above the waterline, proceeding below it and then right the way down to where the crack met the waterbed. High-strength adhesion was achieved between the putty and the wall. Once cured, AB Original formed a rock-hard material to permanently fill the crack.

After the repair was completed, water levels were carefully monitored. A very small leak remained, identified as being at the crack’s widest point near the riverbed. During the initial repair, it had been impossible to tell if all underwater areas in the wall had been sealed.

Further AB Original was applied at the base of the wall on a return visit. This brought the amount of water being drawn by the farm from the river back to expected levels, indicating that the crack had been successfully repaired.

Given the challenging nature of underwater repairs, the Environment Agency were delighted to have discovered such a versatile material capable of being effective underwater. They have since begun using AB Original for other applications and projects.

If you have an application you would like to enquire about, then please get in touch

Call: +44 (0)1444 831 459

Email: sales@sylmasta.com