The seventy pound bilge pipe repair which kept a multimillion dollar superyacht sailing safely

A leaking bilge pipe on board a multimillion dollar superyacht undergoes repair after corrosion at a welded joint caused a hole to appear in an area of the steel line where it was impossible to fit a clamp.

Case Study Data

Site

Superyacht

Location

United Kingdom

Repair Type

No pressure pipe repair

Defect

Hole in a steel bilge pipe

Products Used

Wrap & Seal Pipe Burst Tape

Self-amalgamating silicone repair tape fuses to form a solid rubber band, sealing high pressure leaks

SylWrap HD Pipe Repair Bandage

Composite repair wrap with water activated resin sets rock hard to reinforce and protect repairs

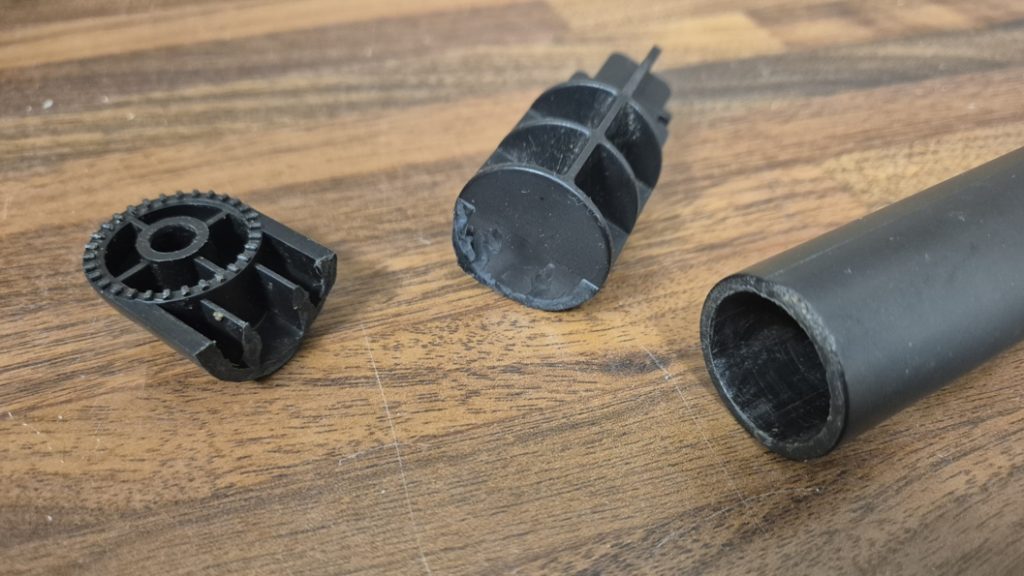

SylWrap Pipe Repair Contractor Case

Products supplied in a Contractor Case, enabling up to six live leak repairs to be made to pipes of different diameters

Case Study PDF

Case Study Details

Bilge pumps are one of the most important systems on any boat for keeping the vessel dry and safe. Water naturally collects at the lowest point on board a boat from everyday sources like rainwater, waves when sailing rough seas and spray.

The bilge pump removes this excess water and other fluids which may have found their way to the bottom of the vessel – such as engine oil – by pumping it through a series of pipes and out via an exit hole in the hull.

This prevents flooding impacting the balance of the boat and causing overflow into other areas. Oily water coming into contact with machinery or electrics in the engine room for example can cause serious problems, potentially destroying a boat’s system.

In the event of a hull breach, a bilge pump removing water as it is being taken onboard buys time to slow or repair the leak. If major damage is obtained, the bilge pump allows for safe evacuation by helping keep the vessel afloat for longer than would otherwise be possible.

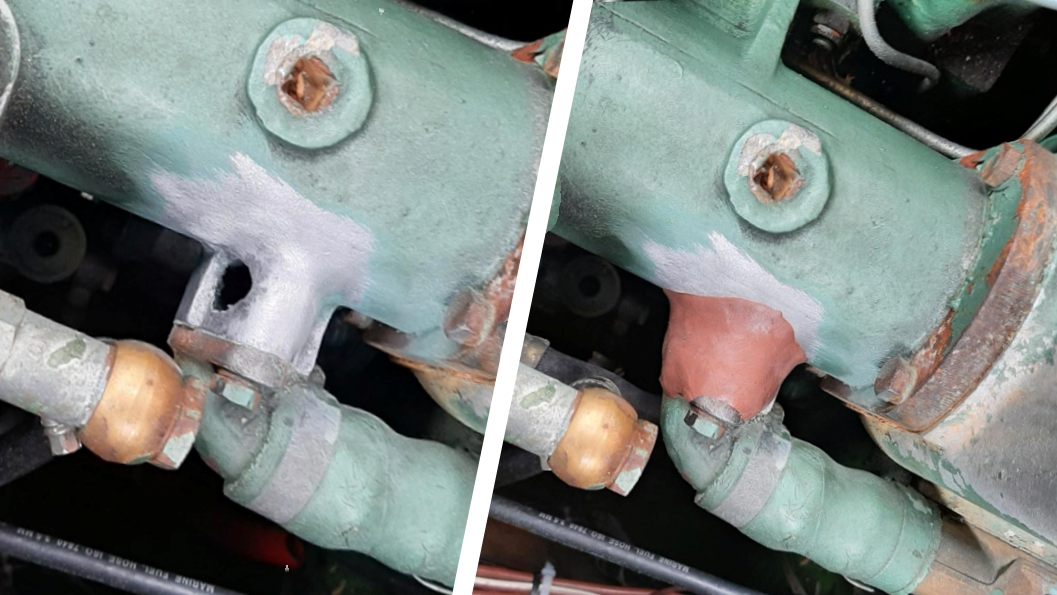

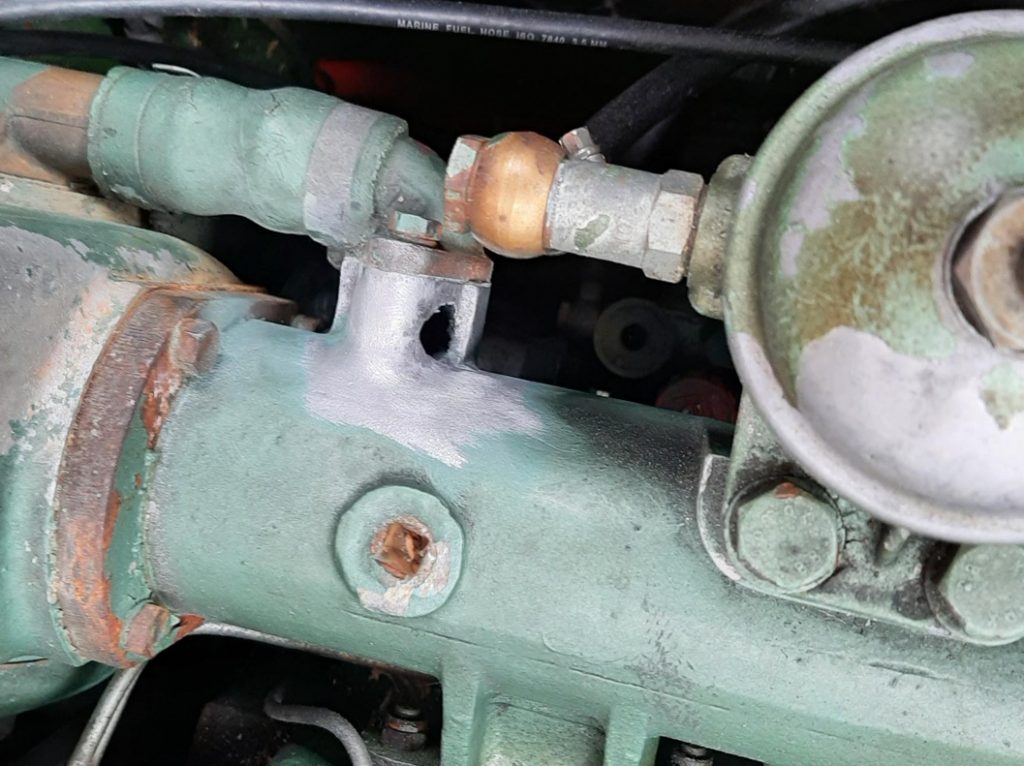

Corrosion had caused the leak in the superyacht bilge pipe by attacking the steel at a welded joint. The subsequent hole was close to a 90-degree elbow and the hull of the boat.

It was also surrounded by other pipes and equipment, making it impossible to repair with a clamp. With water jetting out the pipe whenever the bilge pump went into operation, the hole needed to be urgently sealed until a new pipe could be fabricated and installed.

The superyacht were sent a SylWrap Pipe Repair Contractor Case, from which Wrap & Seal Pipe Burst Tape was used to seal the leak. Wrap & Seal is a self-amalgamating repair tape with a unique tapered profile which stretches by three times its length.

As it was wrapped around the pipe, it fused to form a solid rubber band capable of containing the water sent through the line by the bilge pump at around 2 bar pressure.

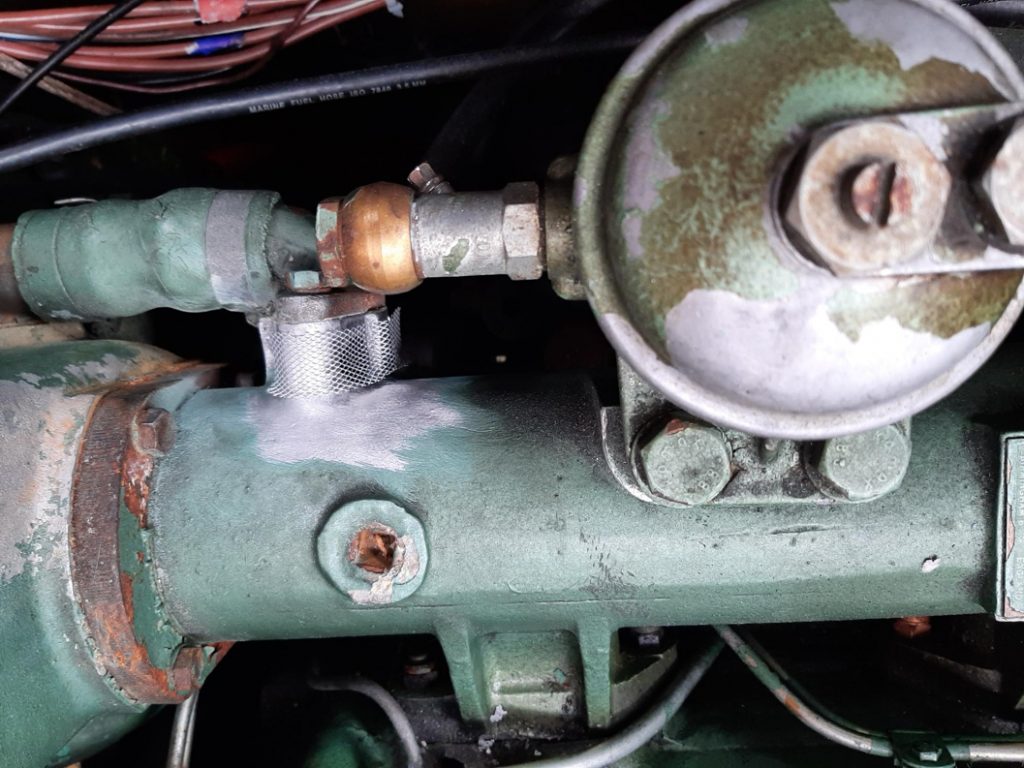

The repair was then reinforced using a SylWrap HD Pipe Repair Bandage. SylWrap HD is a composite wrap with a water activated resin. It was wrapped and smoothed around the pipe, curing in minutes to form a rock hard, impact resistant sleeve.

Completing the bilge pipe repair took under 30 minutes at a material cost of a little less than £70. And having discovered how quick and easy a SylWrap repair is, the superyacht now permanently carries a Pipe Repair Contractor Case on board.

The Case contains enough products to make up to six live leak repairs to pipes of different diameters. It is easily stored onboard and means repairs can be made to any boat pipes on the superyacht as soon as leaks develop – even when sailing the high seas.

If you have an application you would like to enquire about, then please get in touch

+44 (0)1444 831 459

Email: sales@sylmasta.com