Description

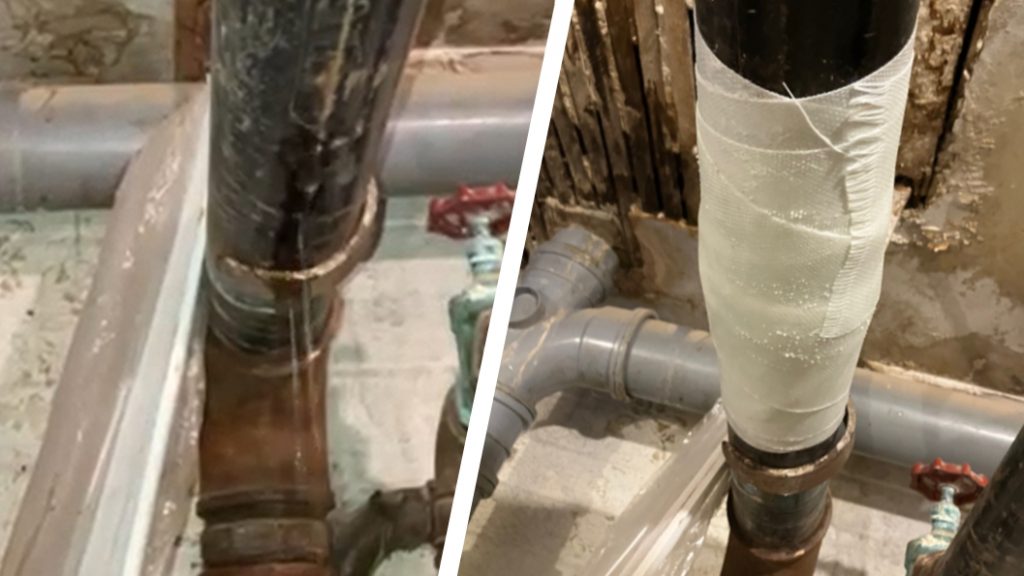

Wrap & Seal Pipe Burst Tape is a self-amalgamating waterproof pipe repair tape which seals live leaks on pipes made from copper, PVC plastic, steel, malleable iron and many other materials.

The tape stretches by three times its length. As it is wrapped around a pipe, it fuses to form a solid rubber band which exerts maximum pressure over the hole or crack to contain pipe content.

Multiple Wrap & Seals applied on top of each other will fuse together in the same way and can build a repair capable of holding up to 30 bar pressure.

Wrap & Seal is temperature resistant to 200°C and effective on pipes carrying hot water and chemicals. It is used in applications ranging from small domestic plumbing problems through to large scale industrial pipe repairs.

Because Wrap & Seal is effective on live leaks, it avoids costly and disruptive shutdowns of systems. Wrap & Seal is WRAS approved, meaning that it can be used safely with drinking water.

Wrap & Seal Pipe Burst Tape details – how to repair a leaking pipe with waterproof tape

Wrap & Seal is easy to use. Depending on the size and pressure of the pipe, repairs can be carried out in under 15 minutes by following the simple instructions provided.

The repair begins by anchoring the waterproof tape next to the leak area. Using the centre line as a guide, you stretch the tape to its maximum and wrap around the pipe until it runs out.

The unique tapered profile of Wrap & Seal prevents water from tracking underneath, enabling it to seal leaks quicker than other repair tapes.

If the leak is not sealed after application of one Wrap & Seal, further tapes should be added on top to increase pressure resistance.

If you are undertaking a high pressure repair or are unsure of how many tapes are required, please use the Repair Calculator tab to determine the quantity and size of Wrap & Seal required.

When repairing holes up to 20mm on pipes in excess of 150mm, a SylPad Pressure Resistance Multiplier can be used in conjunction with Wrap & Seal.

SylPad better concentrates the elastic force of the tape directly over the leak on larger diameter pipework, multiplying pressure resistance by up to three times.

Repairs made with Wrap & Seal should be reinforced by applying a SylWrap Pipe Repair Bandage over the tape. The Bandage offers a rock hard, impact resistant layer of protection which turns the repair permanent.

Wrap & Seal and SylWrap Bandage can be purchased together in the Universal Pipe Repair Kit which contains all the equipment needed for fixing live leaks in an emergency. For a kit that allows for multiple pipe repairs to be carried out, please see the Contractor Case.

Benefits of Wrap & Seal Pipe Burst Tape

- Tape is extra thick and stretches by 300% for a high pressure seal

- Easy to use – just follow the instructions provided to tape the leaking pipe

- Repairs can be carried out to pipes without the need to turn off flow

- Tape can be easily removed if necessary and leaves no residue

Applications

- Copper pipe repair, PVC plastic pipe repair, steel pipe repair, iron pipe repair, GRP pipe repair, ceramic pipe repair, concrete pipe repair, lead pipe repair, rubber pipe repair

- Domestic plumbing repairs and large scale industrial applications

- WRAS approved for repairs to pipes carrying drinking water

- Repairs to non-plumbing pipes, such as car exhausts and hoses

Repair Calculator

The below Wrap & Seal Calculator can determine the recommended number of Wrap & Seal Pipe Burst Tapes required to seal a live leak based on pipe diameter and pressure.

Enter the diameter of the pipe in millimetres, water pressure and the size of the hole requiring sealing in millimetres. The safety factor is a multiple to include a margin of safety. For example, if pipe pressure is 2 bar and you selected a safety factor of two, the calculator will formulate a repair capable of withstanding 4 bar.

After entering your data, selecting the size of Wrap & Seal will determine how many of that specific tape are required for your repair. Repairs being made to pipes in excess of 150mm diameter with Wrap & Seal PB-50x4m or PB-50x11m should be made in conjunction with SylPad.

Calculations serve as a guide to potential maximum pressure resistance only. Actual pressure resistance depends upon pipe material, condition, hole size, leak type and tension maintained during wrapping. If you are unsure, more than one Wrap & Seal can be used to stop the leak.

Videos

Emergency live leak repair using Wrap & Seal

This demonstration video filmed at Sylmasta HQ shows Wrap & Seal repairing a 3 bar live leak through a 3mm pinhole in a stainless steel pipe.

The application was completed in under 10 minutes and the repair tested afterwards by increasing pressure up to 5 bar. The solid rubber band formed by Wrap & Seal easily withstood the sudden fluctuation.

Permanent pipe repair with Wrap & Seal and SylWrap HD

Wrap & Seal Pipe Burst Tape is used to seal a pressurised leak on a steel pipe during a live demonstration at a water company.

In this repair, the Wrap & Seal is applied before being overwrapped with SylWrap HD Bandage for a permanent repair. Please see SylWrap Universal Pipe Repair Kits for more information.

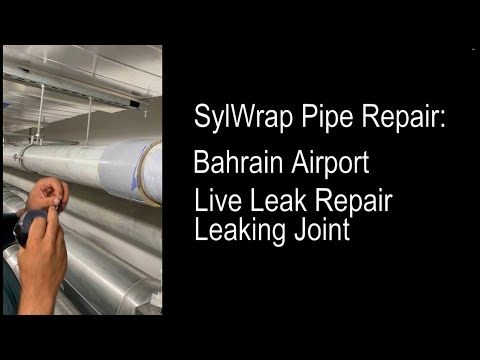

Leaking step joint repair

The maintenance team at Bahrain International Airport use Wrap & Seal to make a live leak repair to a UPVC pipe step joint.

A repair is built up and around the step before being reinforced with SylWrap HD Bandage, sealing the pipe in under 30 minutes whilst the system remained in operation with no disruption to the airport.

Increasing Wrap & Seal pressure resistance with SylPad

SylPad Pressure Resistance Multiplier increases the pressure resistance of Wrap & Seal by up to three times when repairing holes on pipe diameters in excess of 150mm using PB-50x4m and PB-50x11m tapes.

This video shows the live leak repair of a 7.2mm hole in a 450mm steel pipe operating at 3 bar. Such a repair without SylPad would require four 50mm x 4m Tapes.

Using SylPad, the leak was sealed with one tape. With two further tapes added, the completed repair was capable of holding 9 bar pressure.

Electrical Repair

Wrap & Seal can also be used in electrical applications for insulation and repairing damaged cables.

It offers a superior alternative to traditional adhesive electrical tapes because it fuses together and turns into a solid rubber band. This makes Wrap & Seal ideal for wrapping damaged wires, insulating terminal blocks, sealing around cable glands and wrapping and sealing junction blocks.

Only a minor stretch and one layer of Wrap & Seal are necessary when carrying out an electrical repair, meaning one roll can be used for multiple repairs.

When sealing junction boxes against moisture, it is recommended the cavity is first filled with Pack & Seal non-setting insulation putty first, before being wrapped with Wrap & Seal.

Applications

- Wrapping damaged cables

- Insulating terminal blocks

- Sealing around cable glands

- Wrapping & sealing junction boxes

Benefits

- Unlike other electrical tapes, Wrap & Seal self fuses

- Only a small amount of tape is required per repair

- Quick and easy to use