Description

The SylWrap Pipe Repair Contractor Case contains enough products to make up to six emergency live leak repairs on pipes of all materials ranging from 15mm to 600mm diameter.

It has been designed for regular users, offering a cheaper cost per repair than when buying individual Pipe Repair Kits. The red case itself is robust and easy to store both on the van and on site.

Whenever an emergency pipe repair is required, the user simply has to reach for the Case, where they will find everything they need to permanently fix a burst or leaking pipe in under 30 minutes.

Water companies in the United Kingdom, Mexico, Malaysia and Canada all equip their engineers with Contractor Cases for the ease and speed with which they repair leaks once detected.

The Contractor Case repairs pipes made of copper, PVC plastic, steel, stainless steel, malleable iron, GRP, ceramic, clay, concrete, lead, and rubber.

Repairs can be made around difficult elbow, tee and welded joints – offering a versatile and lightweight alternative to heavy, bulky pipe repair clamps.

All the products in the Contractor Case have been WRAS approved and so can be used safely on pipes carrying drinking water. Repairs are pressure resistant up to 30 bar, temperature resistant to 200ºC and effective on pipes carrying hot and cold water and chemicals.

SylWrap Pipe Repair Contractor Case details – How to carry out an emergency pipe repair

Each Contractor Case contains Superfast Epoxy Putty, Wrap & Seal Pipe Burst Tape and SylWrap HD Pipe Repair Bandages.

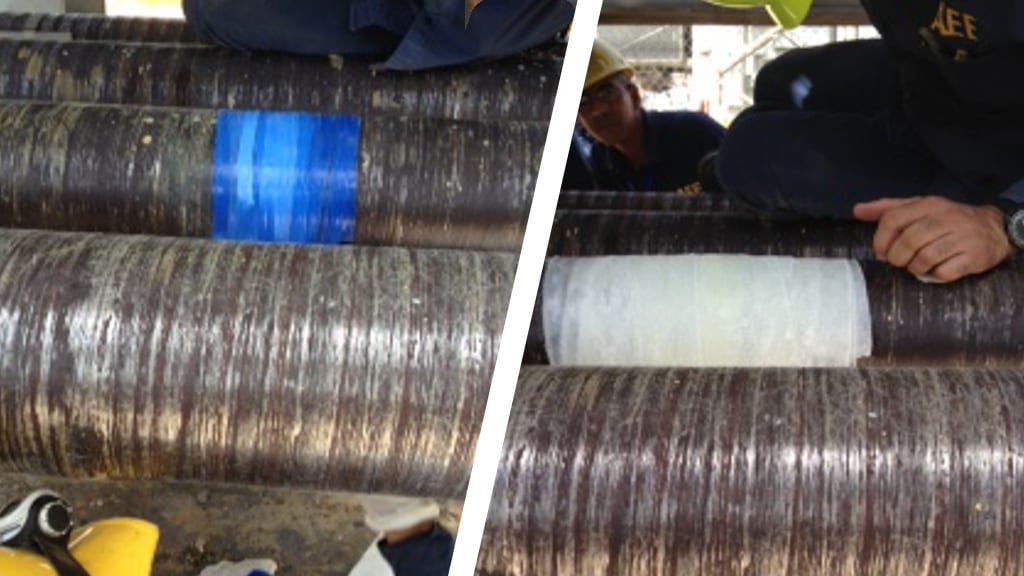

Where pressure cannot be turned off, Wrap & Seal is used to seal the leak. The self-amalgamating waterproof repair tape stretches by 300%, bonding to both the pipe surface and itself as it is wrapped. Once fused, it forms a solid rubber band containing pipe content.

Multiple Wrap & Seals applied on top of each other will fuse together in the same way, building a live leak repair with pressure resistance up to 30 bar.

If you are undertaking a high pressure industrial application, please go to the Repair Calculator tab and enter information about your repair to determine the number of tapes required.

Contractor Cases covering pipes over 150mm diameter include a SylPad Pressure Resistance Multiplier. SylPad is used with Wrap & Seal to better concentrate the pressure of the Tape directly over the leak on larger pipes, multiplying pressure resistance by up to three times.

Where pressure can be turned off, Superfast Epoxy Putty is used to seal the leak. The putty is kneaded by hand until turning a uniform colour.

It is then pushed into the hole or crack in the pipe, where it will harden to fill the damage. Repairs made with Superfast Epoxy Putty are pressure resistant to 30 bar.

The application is completed by overwrapping the initial sealant with SylWrap HD Pipe Repair Bandage. Wetting the bandage activates the resin.

SylWrap HD is then wrapped and smoothed over the repair area. It will set in around five minutes to form an impact resistant, rock hard layer of protection around the pipe.

There are 12 different variations of the Contractor Case available. Each Case contains different product quantities for the repair of different pipe sizes.

For an exact breakdown of what each Case contains and the pipe diameters Sylmasta recommend its use with, please see the Size Guide tab.

Should you require further information about the most suitable Contractor Case for your type of application, please contact Sylmasta and a technician will be happy to advise.

If you do not see a Contractor Case listed which meets your requirements, Sylmasta can also offer customised Contractor Cases tailor made to your specific needs.

Benefits of a SylWrap Pipe Repair Contractor Case

- Contains enough products to carry out up to six live leak repairs at a cheaper cost per repair than purchasing individual kits

- Easy to store on site or on the van. As soon as an emergency pipe repair is required, the Case is there to repair the problem

- Repairs can be carried out in under 30 minutes by simply following the instructions provided

- Offers a low-cost alternative to hiring a contractor or seeking replacement parts

Applications

- Copper pipe repair, PVC plastic pipe repair, steel pipe repair, iron pipe repair, GRP pipe repair, ceramic pipe repair, concrete pipe repair, lead pipe repair, rubber pipe repair

- Regular users who require speed and ease of use, such as water companies, treatment works, petrochemical plants and oil rigs

- WRAS approved for repairs to pipes carrying drinking water

- High pressure repairs up to 30bar and extreme temperature repairs to 200ºC