This video was filmed during product testing of Wrap & Seal Pipe Burst Tape at Sylmasta HQ and shows how our self-amalgamating waterproof repair tape can seal a leaking pipe even when pressure remains on .

About this Pipe Repair Video

Wrap & Seal Pipe Burst Tape is a self-amalgamating waterproof repair tape capable of sealing online leaks.

It stretches by three times its length when wrapped around a pipe, fusing to form a solid rubber band which creates a high-pressure seal containing pipe content.

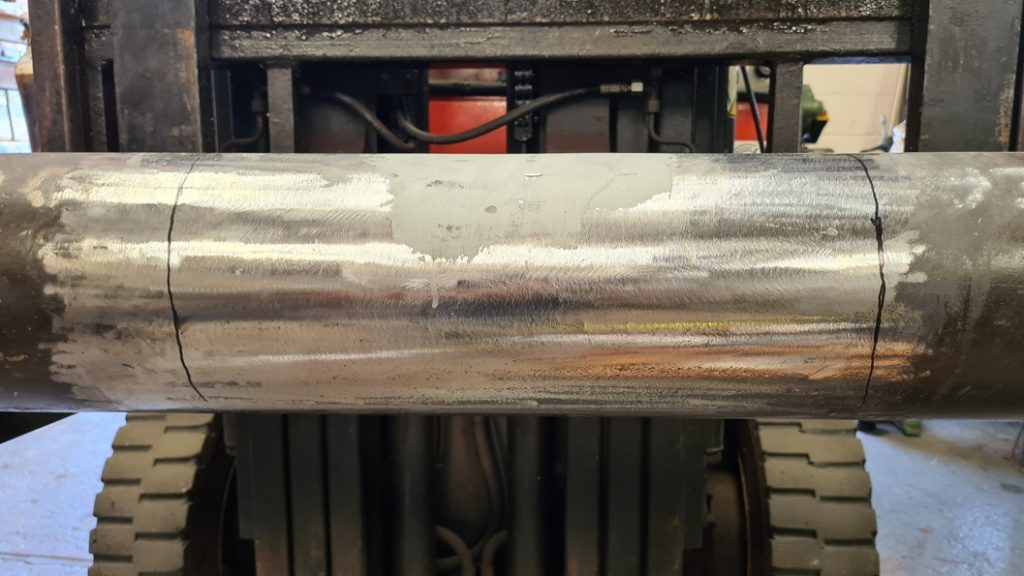

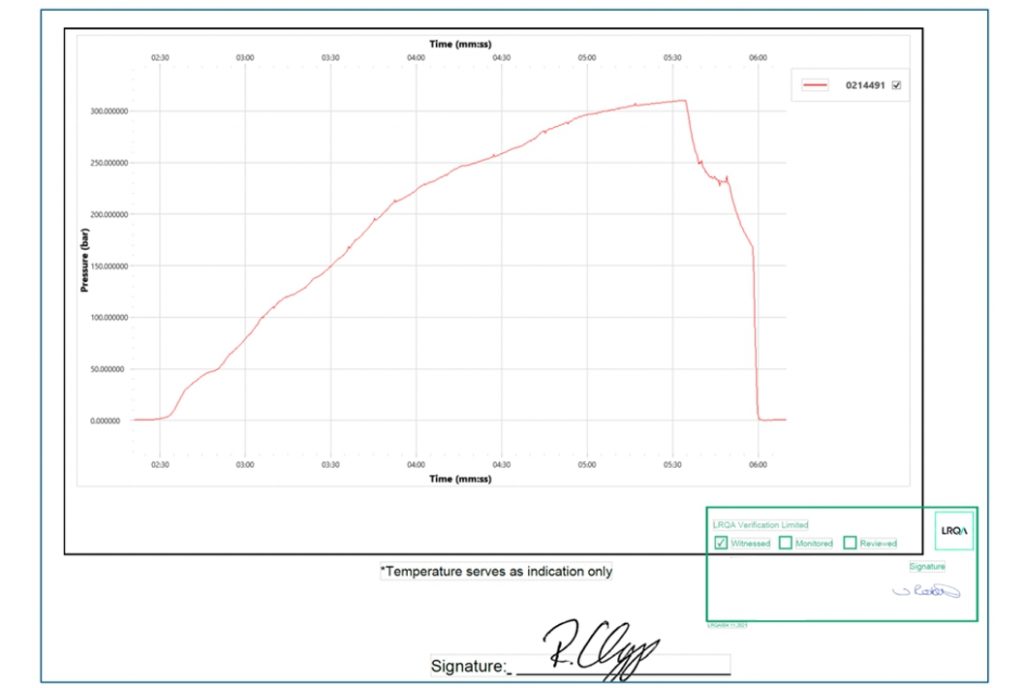

This video was filmed during product testing at Sylmasta HQ in the United Kingdom. A 3mm pinhole was drilled into a stainless steel pipe test rig. Pressure was set at 3 bar whilst a Sylmasta technician carried out a live leak repair.

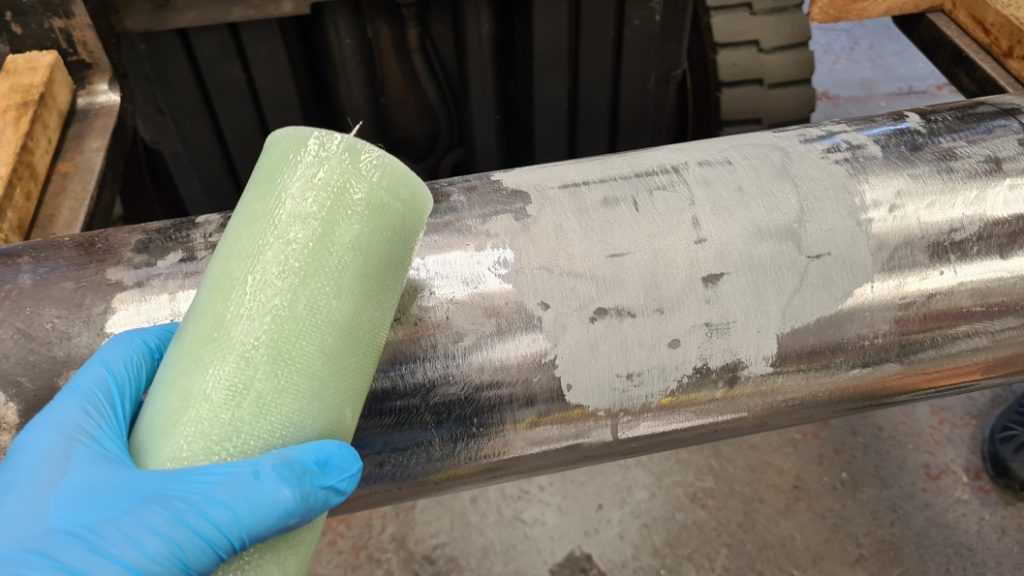

To start the repair, the release film was peeled back from the start of a 50mm x 4m Wrap & Seal Tape and anchored to the side of the leak. One full wrap around the pipe ensured the tape gripped to itself.

It was then wrapped towards the leak whilst being stretched as much as possible, up to the maximum 300 percent. The release film was removed as the application progressed with the tape overlapped by 50 percent per wrap.

Once the leak was reached, Wrap & Seal was applied directly over it with as much stretch as possible. The leak was not chased; even though water was weeping out the side of the repair, wrapping continued to concentrate over the pinhole.

Each layer increased the resistance of the repair, culminating in a thick rubber ridge bonded to the pipe and exerting maximum pressure to seal the pinhole and any potential leak paths.

The application continued until the entire Wrap & Seal was used. Had water still been escaping the pipe after one tape, another would have been applied on top to continue building up the ridge.

Multiple Wrap & Seal fuse to each other in the same way as a single tape amalgamates. Only when the leak is totally sealed should application of Wrap & Seal stop. It is possible to build a repair with pressure resistance up to 30 bar using multiple tapes.

Once the application had been completed, pressure through the test rig was increased to over 5 bar with no visible signs of leakage or any fluctuations.

Repairs made with Wrap & Seal can be reinforced by applying SylWrap HD Pipe Repair Bandage over the tape. SylWrap comes with a fast-working, water-activated resin.

It sets rock hard within minutes as is it is wrapped and smoothed around a pipe, curing to form an impact resistant outer sleeve.

Both Wrap & Seal and SylWrap HD have WRAS approval, meaning they are certified as safe to use on pipes and fittings carrying drinking water.

How to calculate the number of Wrap & Seal Tapes needed for a repair

The Sylmasta Wrap & Seal Calculator helps determine the number of tapes needed to repair a live leak up to a specified pressure resistance. Enter the diameter of the pipe in millimetres, water pressure and the size of the hole requiring seal.

A safety factor is a multiple to include a margin of safety. If pipe pressure is 3 bar for example and you want a safety factor of two, the calculate will formulate a repair for 6 bar.

After entering the repair data, selecting the size of Wrap & Seal to be used will determine the number of that specific tape for the application.

Repars to pipes in excess of 150mm diameter using Wrap & Seal PB-50x4m or PB-50x11m should be made in conjuntion with SylPad Pressure Resistance Multiplier.

(Calculations serve as a guide to potential maximum pressure resistance only. Actual pressure resistance depends upon pipe material, condition, hole size, leak type and tension maintained during wrapping.)

Live Leak Pipe Repair Products

Wrap & Seal Pipe Burst Tape

Self-amalgamating waterproof pipe repair which fuses together to form a solid rubber band, sealing live leaks

Wrap & Seal Case Studies

Case Study: Major Repair Programme for Critical Pipeline at Mexico Water Treatment Plant

Case Study: Homeowner DIY Repair of 25mm Lead Water Pipe Leaking Inside House Wall

Case Study: Leaking Dishwasher 50mm Plastic Pipe Repair in Golf Clubhouse Kitchen

Case Study: Repair of Leaking Expansion Joint Fitted to Water Main Pipe on UK Road Bridge

Case Study: Bilge Pipe Leaking Through Corroded Welded Joint Repair On Board Superyacht

Case Study: Emergency Live Leak Pipe Repair Keeps Heating on at Nursing Home

If you have an application you would like to enquire about, then please get in touch

Call: +44 (0)1444 831 459

Email: sales@sylmasta.com