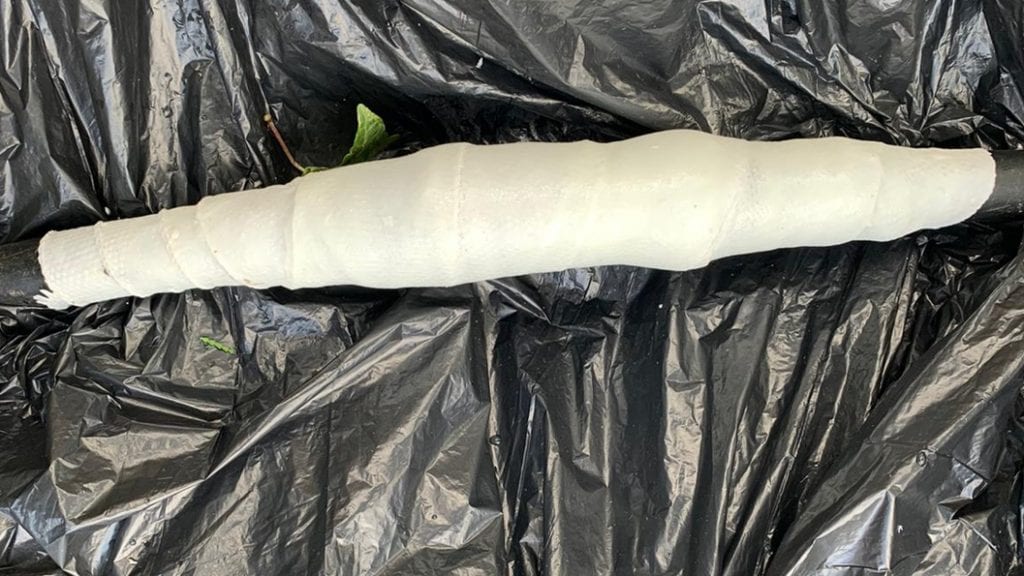

Not sleeping with the fishes – a lengthy split in a plastic hose supplying water to a pond undergoes repair

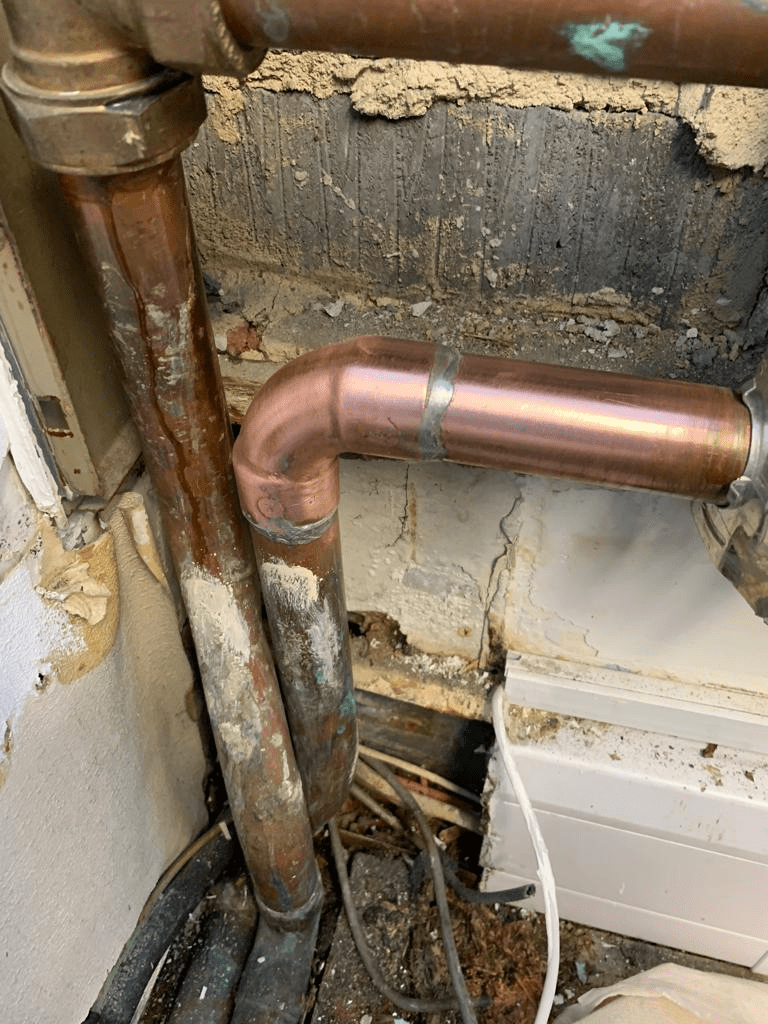

During landscaping work, a pruning saw caused serious damage across a 300mm area of an unnoticed plastic hose supplying water to a pond, including a 80mm longitudinal split requiring repair.

Case Study Data

Site

Domestic Property

Location

United Kingdom

Repair Type

Leak repair

Defect

80mm longitudinal split and 300mm of damage to a plastic supply hose

Products Used

Wrap & Seal Pipe Burst Tape

Self-fusing silicone repair tape used to seal the split and other leaks

SylWrap HD Pipe Repair Bandage

Composite repair wrap provided an impact resistant layer to protect the repair and the hose

SylWrap Universal Pipe Repair Kit

The property owner was supplied with a Universal Pipe Repair Kit containing both products

Case Study PDF

Case Study Details

The pond was on a property cut into the side of a hill with a retaining wall behind it. The roots of shrubs, ivy, and other plants and weeds above the wall were beginning to cause damage to the structure and so the property owner decided to cut some of them away with a pruning saw.

Unfortunately, the owner did not realise that buried just beneath the soil was a hose made from industrial grade plastic supplying water to the pond. As they attempted to remove the shrubs using the saw, they inadvertently cut into the hose.

The damage to the hose was severe with a 80mm longitudinal split from which pressurised water was spraying out. There were several smaller leaks either side of the main split, leaving a 300mm area of hose requiring repair.

Gaining access to make a hose repair was extremely difficult because of the roots, the shrubs and the proximity of the retaining wall. To repair the split in the plastic hose, a versatile solution was therefore needed.

Sylmasta supplied the property owner with a SylWrap Universal Pipe Repair Kit for sealing live leaks, containing SylWrap HD Pipe Repair Bandage and Wrap & Seal Pipe Burst Tape. An additional roll of Wrap & Seal was included due to the 300mm coverage of the repair area.

Water supply was turned off and the hose was cleaned to remove all traces of soil. A plastic sheet was then placed underneath the hose to prevent any further soil or grit being picked up during the application of the Wrap & Seal, which was wrapped across the entire damaged section.

Despite the space constraints around the hose, the Wrap & Seal was successfully stretched by the maximum 300 percent. It fused to form a solid rubber band which sealed the 80mm split and the other smaller leaks present.

The repair was finished by wrapping SylWrap HD over the Tape. The water-activated composite repair wrap provided a rock hard, impact resistant layer in minutes to protect the hose prior to it being reburied in the ground.

Completing the repair took less than 30 minutes and cost under £40. Afterwards, the property owner contacted Sylmasta to say: “There are no longer any leaks in the hose, so I am very happy with the repair.”

“SylWrap is an excellent piece of kit which I wish I had come across years ago and the technical assistance I received from Sylmasta was very much appreciated.”

If you have an application you would like to enquire about, then please get in touch

Call: +44 (0)1444 831 459

Email: sales@sylmasta.com