Epoxy putty sticks for the global market made in the United Kingdom

Sylmasta have invested heavily in bringing the latest epoxy putty stick manufacturing machinery and technology to our site in the United Kingdom, meaning we are the only supplier currently making its own sticks in Europe.

These sticks are shipped worldwide from our HQ in Sussex, around 50 miles (80 kilometres) south of London. They are supplied under our Superfast brand and are trusted by some of the biggest names in maintenance adhesives.

The benefits of Sylmasta epoxy putty sticks made in the UK

Epoxy putty stick manufacturing was pioneered in the United States. It removed the need for precise measuring and mixing of separate components of resin and hardener by supplying pre-measured portions of each in the correct 1:1 ratio in a single, easy-to-use stick.

But recent global events have highlighted problems with overreliance on the US and Asian markets for importation.

Exports out of Asia were disrupted during the Covid-19 pandemic and its aftermath. In the USA, uncertainty over tariffs has made importing materials for making sticks and exporting the finished product challenging.

Epoxy putty sticks made in the UK by Sylmasta offer numerous advantages. In terms of the sticks themselves, we can provide customised formulations to meet client needs, including adjustments to cure times and colour.

We employ lean manufacturing principles, meaning everything is made to order – guaranteeing fresh product and low minimum order quantities.

Customers who use Sylmasta as their epoxy putty stick supplier enter a reliable supply chain with reduced lead times and expert technical help readily available for specific applications.bee

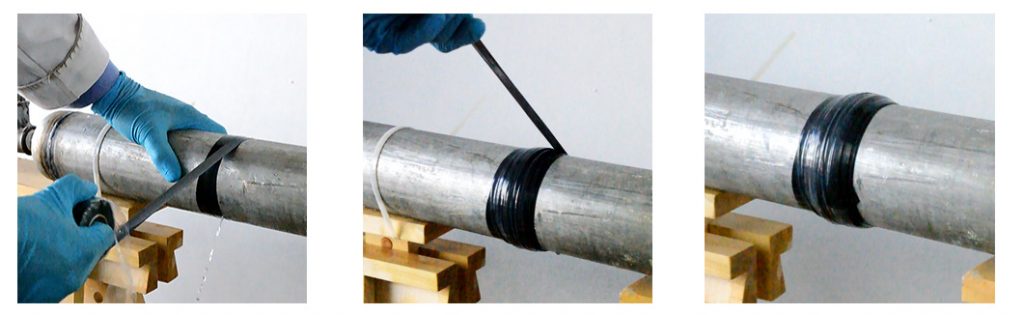

A good example of the benefits of Sylmasta epoxy putty sticks comes from 2024, when we produced and shipped a significant quantity of product to a local authority in Canada to repair a leaking underground water main.

Within five days of us receiving the order, the sticks were on-site and ready to be used by engineers in British Columbia.

The Sylmasta epoxy putty stick range

Sylmasta make the following epoxy putty sticks as standard:

- Steel Stick – Steel filled with a five-minute work time and WRAS approval for use with pipes and fittings carrying drinking water. Sets to a grey, metallic-like colour.

- Aluminium Stick – Epoxy putty formulated for the repair and bonding of aluminium, other alloys and different types of metalwork. Sets grey with a four-minute work time.

- Copper Stick – Copper-filled epoxy putty sets to that colour for the rapid repair of copper, brass, bronze and other non-ferrous metals. Has a three-minute work time.

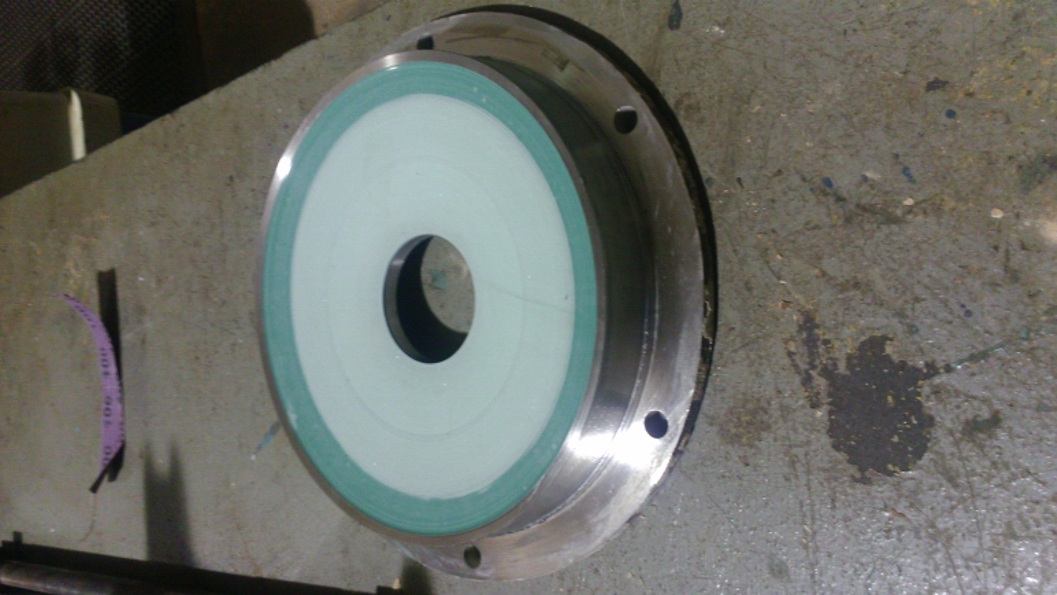

- Aqua PW Stick – Specialist epoxy putty formulated for very high wet surface and underwater adhesion. Sets white, has a five-minute work time and WRAS approval for use with potable water.

- Titanium Stick – High temperature epoxy putty with resistance up to 280ºC. It sets to a golden colour, has a 90-minute work time and will bond to most materials operating under extreme heat.

- Concrete Stick – Concrete-filled epoxy putty which sets grey for the uniform repair of concrete, stone and masonry. Has a quick four-minute work time.

- Plastic Stick – Plastic-filled epoxy putty which bonds and repairs all major types of plastic, except polyolefins. It comes with a 20-minute work time and sets white.

- Wood Stick – Wood-filled epoxy putty cures to a material sharing an appearance, hardness and density similar to wood. Has a 15-minute work time, offering a little longer to shape and form the putty.

- General Purpose Epoxy Putty Stick – Sylmasta AB Original is ceramic-filled, bonds to all materials and comes with a two-hour work time for complex applications requiring longer to handle the putty before curing.

All Sylmasta epoxy putty sticks can be made as standard 200mm diameter sticks or 300mm diameter ‘fat’ sticks.

If you would like to learn more about our epoxy putties or discuss the possibility of having Sylmasta manufacture epoxy putty sticks for your business, please contact Sylmasta via email or on +44 (0)1444 831459