Brush up on your knowledge of brushable epoxy

Imagine if you could do something as a simple as paint a pipe, a part or a structure to provide it with a metal layer of armour capable of resisting corrosion, abrasion and chemical attack. Welcome to the world of the epoxy coating.

They say prevention is better than a cure and prevention of degrading surfaces does not come any better than epoxy coating. Within a couple of hours, a smooth, hard surface can be created that repairs existing wear and tear and prevents against future damage.

Here is the Sylmasta guide to epoxy coatings and how they can help you refurbish and extend the lifespan of systems, with potential savings of thousands and thousands of pounds.

What is an epoxy coating?

Epoxy coatings are made up of two separate liquid parts, one containing resin and the other containing hardener.

When these parts are mixed together, a chemical reaction takes place which results in the epoxy coating setting to form a hard wearing, ultra smooth coating.

What are epoxy coatings used for?

Epoxy coatings have two main uses. The first is for protecting and refurbishing structures, pipes, machinery and surfaces by providing them with an ultra-hard outer layer.

New parts which are coated with a brushable epoxy are protected against corrosion, abrasion, chemical attack, pitting, erosion and cavitation.

Old, worn or damaged parts are restored when an epoxy coating is applied via the creation of a new, hard layer which extends the lifespan of parts.

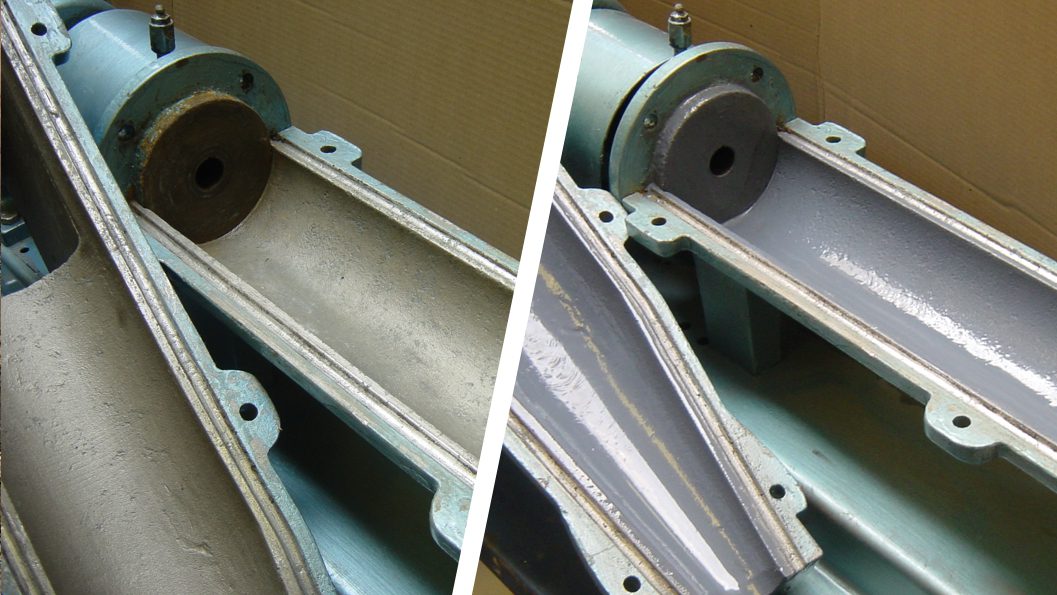

Take this repair made to aluminium extruder barrels in a pug mill putty machine for example. The rough initial finish of the barrels combined with the silica-filled putty causing damage as it was extruded had caused the aluminium to become worn.

This in turn was impacting on the efficiency of the machinery, as putty was being extruded at a reduced rate. Cleaning of the barrels also took longer because of the damage to the surface.

Applying an epoxy coating to the barrels repaired the worn surfaces, protected them from future abrasion caused by the putty and created an ultra-smooth layer for the putty to slide down, improving extrusion rate.

Epoxy coatings are also used for high-strength bonding of materials. Whilst still a liquid, they remain gel-like and sticky, during which components can be bonded to them.

When used in floor repair, ant-slip grit can be added to a floor painted with epoxy coating to create a non-slip surface. In pipe repair applications, an epoxy coating improves adhesion between the pipe and composite repair wrap.

How does an epoxy coating work?

Applying an epoxy coating is as simple as painting a wall. Once the two parts have been mixed to the prescribed ratio, a traditional paintbrush is used to coat the surface requiring protection.

The formulation of the epoxy coating will determine the cure time. Sylmasta epoxy coatings come with a 90 minute gel time, enabling more of the epoxy to be mixed without the threat of premature curing.

This is particularly useful in warmer climates, where heat accelerates the work time, reducing how long is available to carry out an application.

To create a pinhole free coating, it is recommended that two coats are used. The re-coating time is 5-8 hours after applying and a full cure is achieved in 24 hours.

Types of epoxy coating

Epoxy coatings can be filled with different materials to improve their effectiveness for use in specific applications, such as corrosion protection or prevention of abrasive wear.

Liquid Metal Epoxy Coating is metal-filled, setting to provide a layer of metallic armour to pipes, structures, machine parts and surfaces. It is formulated to offer excellent protection against corrosion and chemical attack.

Painting worn and damaged parts with Liquid Metal refurbishes them, extending the lifespan of systems. As well as metalwork, Liquid Metal can be used to give most plastics a metal coating.

For protection against surface wear, it is desirable to have an even harder epoxy coating. Ceramic Brushable Blue is ceramic-filled and reinforced with silicone carbide, enabling it to resist and repair damage caused by abrasion.

Sylmasta Epoxy Coatings

-

Ceramic Brushable Blue Epoxy Coating£40.55 – £222.72 inc. Vat

-

Ceramic Brushable Green Epoxy Coating£38.24 – £210.11 inc. Vat

-

Liquid Metal Epoxy Coating£35.40 – £195.11 inc. Vat

If you have any question about which product is most suitable for your repair or require technical assistance, then please contact Sylmasta via email or on +44 (0)1444 831459 and a technician will be happy to advise you.