Welcome to the wonderful world of epoxy putty

Epoxy putty is one of those repair materials that every household should have a supply of. Why? Because it is so versatile that you can use it in almost any job you can think of.

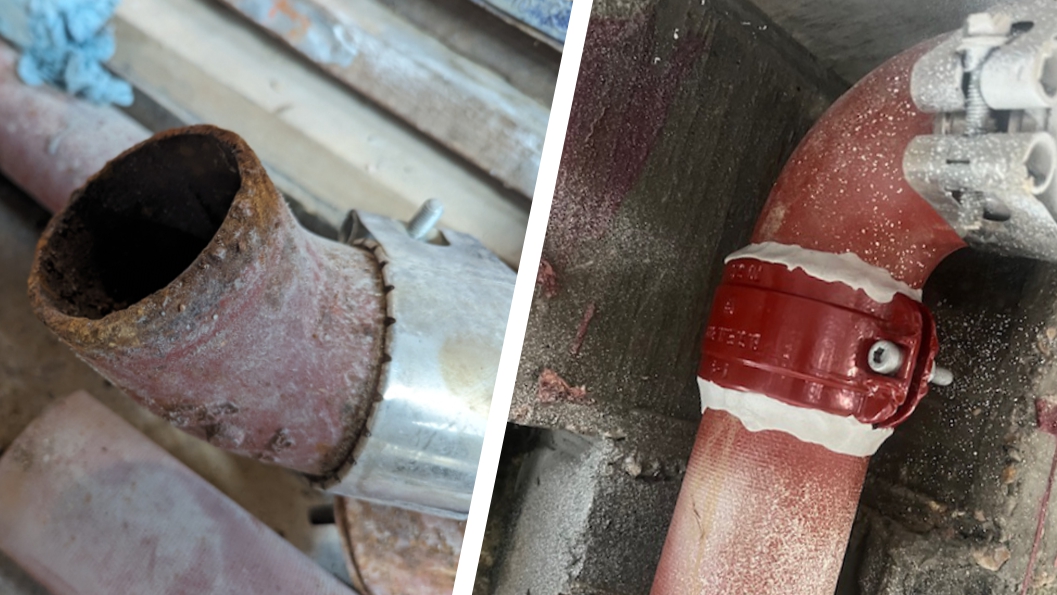

Need to fix a leaking pipe? Use putty to plug the hole. Have a cracked concrete paving slab that requires repair? Use putty to fill the gap.

Bathroom tiles or ceramics that are chipped? Epoxy putty. Wood that could do with filling in? Epoxy putty. Hole in metalwork caused by rust? Epoxy putty.

It is a powerful adhesive. It bonds to virtually any surface. It is waterproof. It can be shaped, moulded, sculpted, drilled, sawed, cut and painted. And perhaps best of all – it is one of the easiest repair compounds to use.

What is epoxy putty?

Epoxy putties are made up of two soft parts. When these two parts are mixed together, a chemical reaction takes place, causing the putty to harden.

Whilst soft, epoxy putty can be kneaded by hand and moulded into use for the repair or bonding task it is required for. By the time it has cured and set, you have a material which can be as hard as steel when measured using the Shore rating.

How does epoxy putty work?

The key component in an epoxy putty is the hardener. The chemistry of the hardener determines how quickly the putty will cure. Some users may want a rapid working putty while others carrying out larger projects or more detailed work might need longer to work with the material.

Take Superfast Steel Epoxy Putty. It has a cure time of five minutes, offering a rapid repair solution for steel, iron and other ferrous metals. It is the perfect epoxy putty for when time is of the essence.

When epoxy putties are used by model makers, sculptors and restorers, they in contrast require time to be able to shape the putty and carve intricate details into their creations.

Over on Sylmasta’s craft, restoration and model making site SylCreate.com, the putties on sale therefore come with a much longer working time of up to two hours – Green Stuff, Magic Sculp and Geomfix Original A+B.

AB Original is Sylmasta’s super-strength repair putty. It also comes with a two working time, allowing for more putty to be mixed without wastage for use in large-scale repair and maintenance tasks.

Because the cure speed of epoxy putty is impacted by heat, putties with long working times are more suitable for warmer climates. AB Original has proven a popular product with Sylmasta’s pipe repair customers in the Middle East.

Types of epoxy putties

Different epoxy putties are formulated for different tasks and use on certain materials. Specialist wood putty for example is coloured brown and will often be wood-filled, allowing it to bond more effectively.

Concrete putty cures to grey to match concrete. Milliput, a Welsh epoxy putty manufacturer, produce a terracotta putty which can be used to repair terracotta and clay ornaments.

Epoxy putties are not just formulated for colour. Specialist formulations are produced for high temperature applications, such as Titanium High Temperature Epoxy Putty which is resistant up to 280°C for use with steam pipes and other pipework in industry.

When it comes to epoxy for domestic plumbing, then finding a putty which is WRAS approved is vital to guarantee the safety of the repair. WRAS approval means that the material in question has been certified for use with drinking water.

Using putties that are not WRAS approved and which encounter water designated for human consumption could lead to contamination – the last thing anyone wants when it comes to fixing a leaking pipe.

Epoxy putty formats

Epoxy putties can come in several formats. The two most common formats are the putty stick and the two-part putty.

The Putty Stick is the easiest to use. It combines the two parts in one handy stick with the hardener running through the middle.

You simply cut off the required amount of putty and knead by hand until it feels ready to apply. Because the Putty Stick is pre-formatted, there is no need to worry about the mixing ratios of the two parts.

Some epoxy putties will come with the two parts kept separate. When this is the case, you take the required amount of each part and mix them together. This allows for greater control over the mixing ratio; including more hardener for example will quicken the working time and can lead to a less sticky putty.

Having such command over the properties of the putty is desirable when it comes to model making, sculpture and other creative tasks. It is much less important in the majority of general repair tasks however, which is why putty sticks are suitable for most maintenance jobs.

One alternative format is the epoxy putty tape or reel. The two parts are combined in one easy-to-store reel and just like with the stick, you cut off the required amount of putty and knead it by hand.

How to use epoxy putty

The biggest selling point of epoxy putty is how easy it is to use. Once you have mixed it by hand, you simply apply it to the material or area requiring repair.

It is soft enough to push into holes and cracks, fixing leaking pipes and creating watertight seals around faucets, drains, and other plumbing parts.

Repairing cracked and chipped masonry and concrete is equally straightforward; just mould the kneaded putty into place. As an adhesive, it can be used to stick one material to another in the same manner that you would apply blue tac.

Once the putty has cured, you can do practically anything to it. Paint it, drill it, saw it. It won’t shrink or pull away.

When you have finished carrying out the repair job or task at hand, then you can keep the remaining putty. All epoxy putties will stay fresh when kept tightly sealed in their original packaging, ready and waiting to serve you again in the future.

Sylmasta Epoxy Putties

-

Sylmasta AB Rapid 5 Minute Epoxy PuttyPrice range: £23.66 through £1,181.81 inc. Vat

Sylmasta AB Rapid 5 Minute Epoxy PuttyPrice range: £23.66 through £1,181.81 inc. Vat -

Sylmasta AB Original Epoxy Repair PuttyPrice range: £15.77 through £1,002.18 inc. Vat

Sylmasta AB Original Epoxy Repair PuttyPrice range: £15.77 through £1,002.18 inc. Vat -

Sylmasta AB Original Epoxy Putty StickPrice range: £15.77 through £266.80 inc. Vat

Sylmasta AB Original Epoxy Putty StickPrice range: £15.77 through £266.80 inc. Vat -

Superfast Titanium Epoxy Putty Stick£15.77 inc. Vat

Superfast Titanium Epoxy Putty Stick£15.77 inc. Vat -

Superfast Aqua Potable Water Epoxy Putty Stick£12.64 inc. Vat

Superfast Aqua Potable Water Epoxy Putty Stick£12.64 inc. Vat -

Superfast Steel Epoxy Putty Stick£12.64 inc. Vat

Superfast Steel Epoxy Putty Stick£12.64 inc. Vat -

Superfast Plastic Epoxy Putty Stick£12.64 inc. Vat

Superfast Plastic Epoxy Putty Stick£12.64 inc. Vat -

Superfast Aluminium Epoxy Putty Stick£12.64 inc. Vat

Superfast Aluminium Epoxy Putty Stick£12.64 inc. Vat -

Superfast Concrete Epoxy Putty Stick£12.64 inc. Vat

Superfast Concrete Epoxy Putty Stick£12.64 inc. Vat

If you have any questions about which product is most suitable for your repair or require technical assistance, then please contact Sylmasta via email or on +44 (0)1444 831459 and a technician will be happy to advise you.