Why flooring and carpeting companies should always be prepared for pipework disasters

Emergency pipe repair is not just for plumbers. Pipes are everywhere and many trades encounter them on a daily basis. Electricians, builders, decorators, gardeners, carpenters, carpet fitters… the list goes on.

Having contact with pipes means that there is always a danger of accidentally cutting into one. When this happens, the damage can be severe, as a family in Hampshire discovered to their cost.

The Newton family were settling into their new home with their 12-month-old baby. Their kitchen had been refurbished and extended, the property newly decorated and new carpets fitted. Only one thing was bothering them – a loud, creaking nose from the floorboards in the bedroom.

They thought it may have been caused by all the construction work below. To get to the bottom of the problem, they called in a trained carpenter to investigate.

The upstairs flooring was chipboard rather than floorboards, so a section had to be cut away to gain access to the RSJ below. It was then decided that additional screws in the joists might reduce the creaking.

Unfortunately, the carpenter had not fully investigated what was lurking underneath the chipboard, resulting in the screws being placed in a perfect line down the centre of the mains water pipe supplying the tank in the loft.

Initially at least, the screws were not a major problem. Worse was to come however when the carpenter went to remove another section of chipboard, only to end up cutting through the pipe with a circular saw.

Catastrophic damage had now been caused to the already perforated pipe. With mains water gushing into the floor space, the family rushed to turn off the supply, only to find that the stopcock was seized up and could not be operated manually.

After some time, a wrench was found and the water turned off. The family then called a plumber to shut off the damaged section of pipe so that the home could still run other water services.

The plumber cut the pipe, plugged what he thought was the end leading to the mains, and turned the water back on. Alas, he had plugged the wrong end and so once more mains water was pumping into the floor space from an open-ended pipe.

Supply was again shut off and the plumber rectified the error. Still, several more gallons of water had been released, adding to the destruction of the home.

The damage led to damp and water ingress in the new kitchen and dining room. Much of downstairs had to be replastered and redecorated, as did the master bedroom where the pipe breach had occurred.

New carpet and underlay had to be fitted and a new living room ceiling. The home was also without water, heating and electricity for four days – hardly a good situation at the best of times, but catastrophic with a 12-month-old baby.

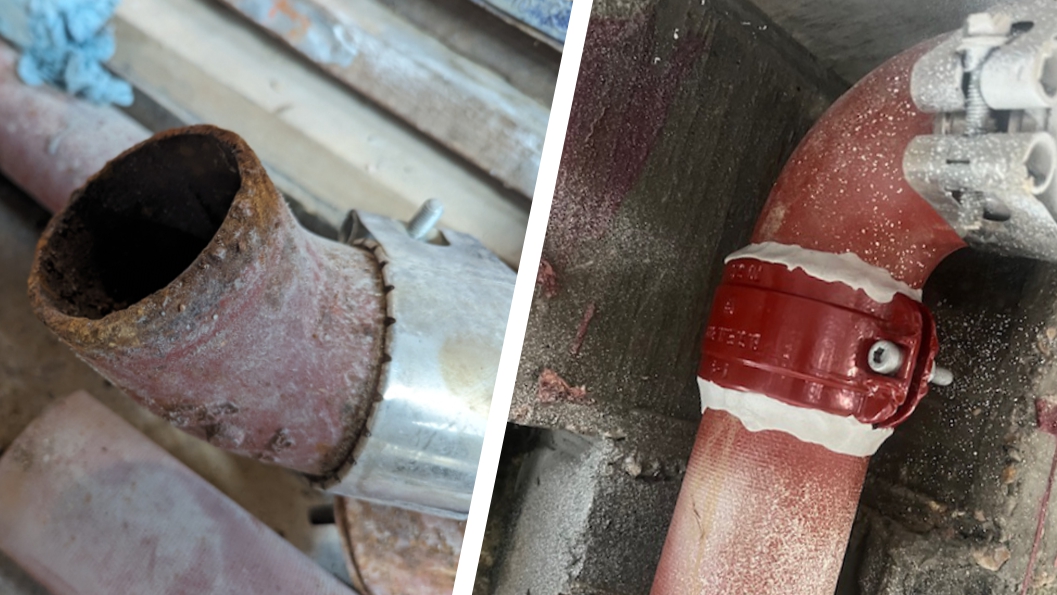

Had the carpenter kept a SylWrap Pipe Repair Kit on his van in case of emergency, then all of that could have been avoided. SylWrap enables any user to permanently repair a leaking pipe in less than 30 minutes even when water flow cannot be turned off.

A SylWrap Kit can make repairs pressure resistant to 30bar and temperature resistant to to 200ºC. They are WRAS approved so can be used safely on pipes carrying drinking water and are effective on pipes of any size made from copper, PVC plastics, steel, stainless steel, malleable iron, GRP, ceramic, clay, concrete, lead, and rubber.

With SylWrap, the leak could have been minimised within minutes, preventing it wreaking such destruction. A full, permanent repair would have made the pipe serviceable and mains water could have been reinstated.

Accidents happen, as the Newton family, the carpenter and the plumber involved found out to their cost. Being prepared for emergencies by carrying a SylWrap Kit can help prevent them turning into the sort of disaster seen in Hampshire.

To speak to a Sylmasta technician about how your company might benefit from stocking SylWrap Pipe Repair solutions in case of an emergency, then please contact Sylmasta via email or on +44 (0)1444 831459.

SylWrap Emergency Pipe Repair Kits

SylWrap Universal Pipe Repair Kit

Contains Superfast Epoxy Putty, Wrap & Seal Pipe Burst Tape and SylWrap HD Pipe Repair Bandage for permanent live leak repairs

SylWrap Pipe Repair Contractor Case

Easy-to-store, robust red case with enough SylWrap Pipe Repair products to make up to six permanent live leak repairs