Say aloha to a sewer force main in Hawaii restored from a corroded state by a repair made using the Sylmasta Pipe Refurbishment System

An engineering company in Hawaii refurbish a severely corroded 30-metre section of 450mm ductile iron sewer force main inside an underground vault, rectifying a previous repair attempt which ended up sandblasting a 75mm round hole in the pipe.

Case Study Data

Site

Sewer force main

Location

Hawaii

Repair Type

Pipe repair and refurbishment

Defect

Severely corroded 450mm ductile iron pipe, including 75mm round hole

Products Used

Industrial Metal Epoxy Paste

Metal-filled epoxy paste used to bridge large holes, rebuild weakened pipes and restore surface profile

Liquid Metal Epoxy Coating

Brush applied coating which cures to a hard wearing, metallic surface for protecting pipes against corrosion

SylWrap Pipe Repair Bandage

Composite repair wrap with water activated resin which sets rock hard to encompass pipes with an impact resistant outer sleeve

Case Study PDF

Case Study Details

The 450mm ductile iron pipe inside the vault was the final section of the sewer force main before it discharged into a manhole housing a gravity collection system. Its operating pressure was around 3 bar.

It was installed in the 1970s. Conditions inside the often-flooded vault over a period of nearly 50 years had led to severe exterior corrosion and a significantly weakened pipe.

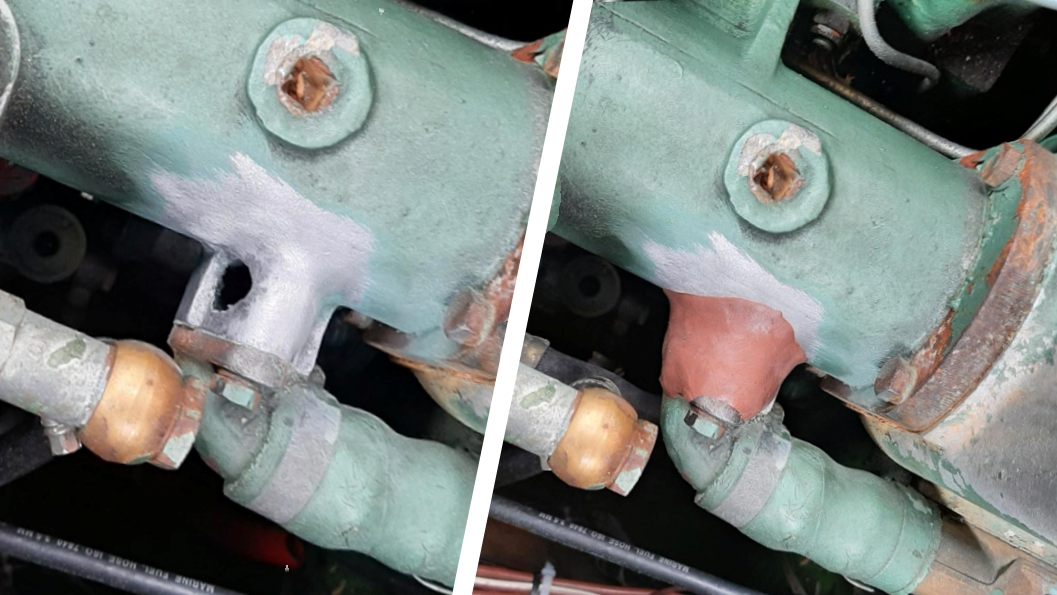

A recent attempt to add structural strength and protect against further corrosion involved sandblasting the line prior to coating with epoxy. Unfortunately, the contractor failed to realise just how weakened the ductile iron had become.

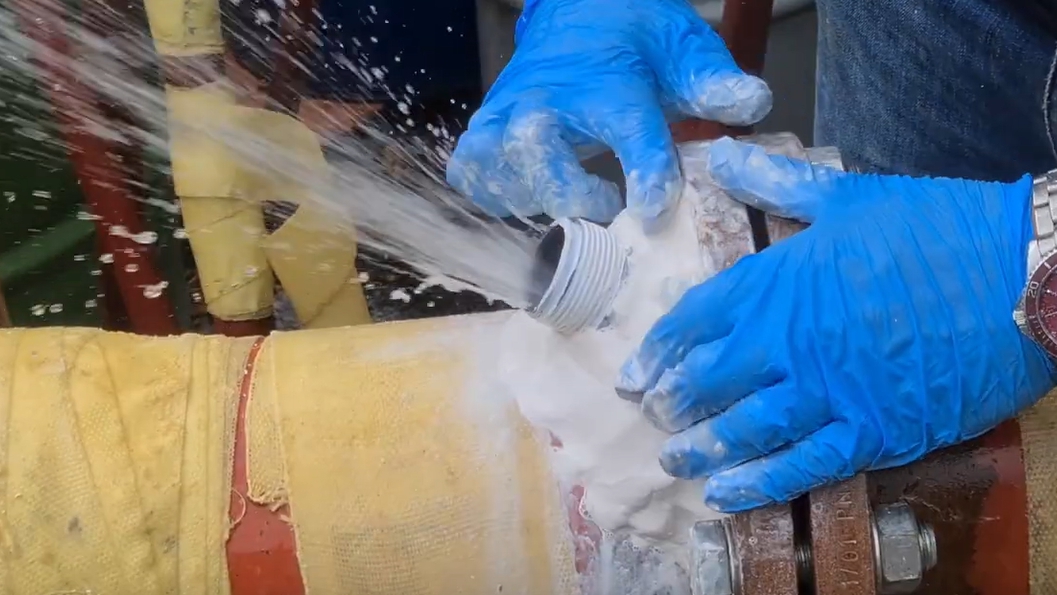

Sandblasting to clean the pipe subsequently put a 75mm round hole in the top of the sewer between a flange and the concrete wall where the main entered the adjacent manhole. Wastewater could escape through this hole when the line was pressurised.

To seal the leak in the pipe, the contractors ordered a pipe repair clamp specifically fabricated for the line. But because the surface was so badly deformed by corrosion, it was impossible for the clamp to achieve a watertight seal. There were also concerns that tightening the clamp fully would further breach the brittle metalwork.

The contractors contacted Sylmasta for assistance with the corroded sewer main repair. They needed to improve the surface profile of the pipe to make the clamp effective, before refurbishing the entire 30-metre section inside the vault to keep the line operational and protect against further degrading.

Any repair method had to take into account the weakness of the line and the damage already done by sandblasting. Sylmasta therefore recommended using Stages 2, 3 and 4 of their Pipe Refurbishment System.

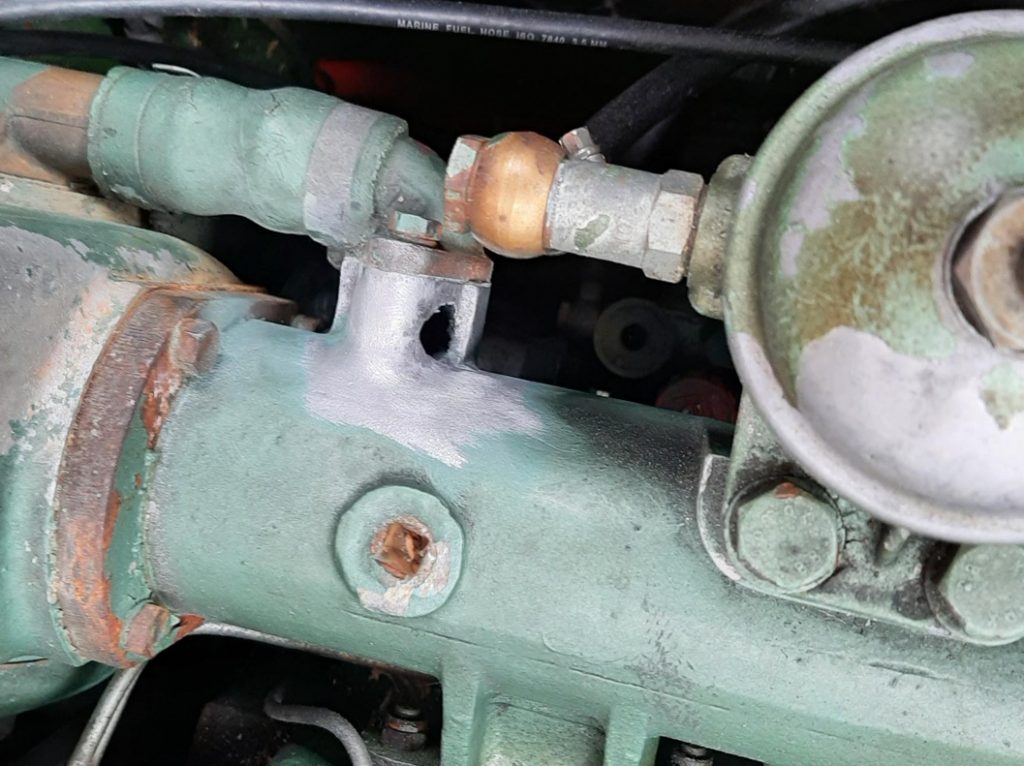

The hole was attended to first. Wire mesh was used to bridge the gap. Industrial Metal Epoxy Paste was then applied around the entire diameter of the pipe between the flange and the wall, including over the hole. The wire mesh prevented any epoxy paste entering the pipe.

Industrial Metal is a two-part epoxy paste used to rebuild weakened metalwork and improve surface condition of pipes. In this application, 5kg of Industrial Metal filled in all imperfections caused by pitting and increased pipe thickness surrounding the hole.

Once cured, Industrial Metal sealed the hole and rebuilt the pipe, leaving it strong enough to withstand the clamp being fitted and smooth enough to ensure a watertight seal could now be achieved.

Industrial Metal could have held the leak of its own accord. The contractors though decided to take a belt and braces approach by also fitting the clamp, seeing as it had been specifically made for this sewer line.

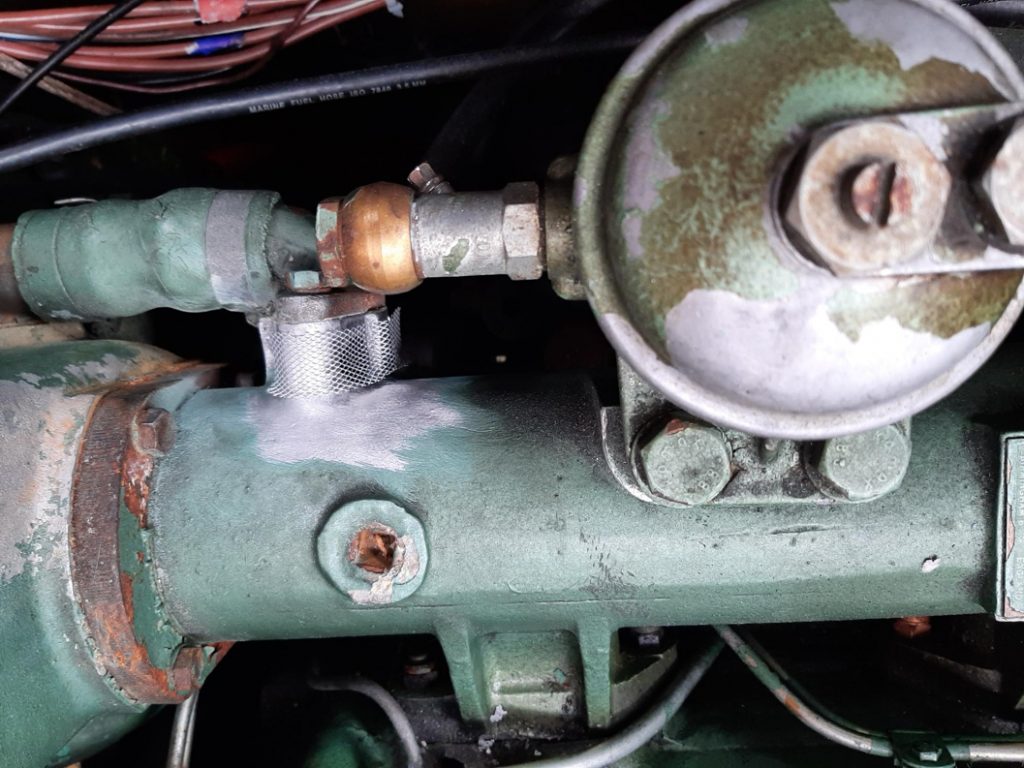

Attention next turned to refurbishing the rest of the corroded sewer main. Loose material was carefully cleaned off using wire brushes before the sewer main was painted with Liquid Metal Epoxy Coating.

10kg of Liquid Metal was used to apply two coatings across the entire 30-metre pipe, the two flanges at either end and the coupling in the middle. Re-coat time was four hours, meaning the application of Liquid Metal took one day.

Liquid Metal cured to create a new, metallic, hard-wearing pipe exterior for the sewer main, providing a shield against corrosion and a waterproof barrier against future leaks.

The final stage of the repair saw the sewer main given further reinforcement using 20 x SYL866HD SylWrap Pipe Repair Bandage. SylWrap Bandage is a composite repair wrap with a water-activated resin.

It was wrapped and smoothed around the whole pipe, curing within minutes to form a rock-hard, impact resistant layer of further protection. Six layers of SylWrap Bandage were used based on the 3 bar operating pressure of the sewer main.

From sealing the hole to reinforcement with SylWrap Bandage, the repair was completed over the course of one week. The contractors were impressed with how easy all three Sylmasta products were to apply given the cramped, wet and dirty conditions inside the vault.

They had originally planned to encase the sewer main in concrete after refurbishment as an additional means of protection. This was no longer deemed necessary once they saw the strength and effectiveness of the repair.

At a total cost of just under $5000 including delivery to Hawaii, refurbishing the corroded sewer force main provided a significant financial saving compared to ripping out the pipe and replacing it.

If you have an application you would like to enquire about, then please get in touch

Call: +44 (0)1444 831 459

Email: sales@sylmasta.com