Composite pipe repair using Sylmasta products exceeds 309.6 bar pressure resistance to qualify for ASME PCC-2 401-III

SylWrap HD Pipe Repair Bandage and Industrial Metal Epoxy Paste make a repair independently witnessed and verified as passing ASME PCC-2 Appendix 401-III – Short Term Spool Survival standard by exceeding 309.6 bar pressure resistance.

Case Study Data

Site

Test site

Location

United Kingdom

Repair Type

Composite pipe repair pressure test

Defect

Carbon steel pipe machined back to 1mm outer wall thickness

Products Used

Industrial Metal Epoxy Paste

Metal filled epoxy paste used to strengthen pipelines by rebuilding weakened outer walls back towards original thickness

SylWrap HD Pipe Repair Bandage

Composite repair wrap with water activated resin sets rock hard to reinforce pipework with a thickened, impact resistant sleeve

Case Study PDF

Case Study Details

ASME PCC-2 Appendix 401-III – Short Term Spool Survival is a test which assesses the ability of a composite pipe repair system to restore the integrity of a weakened pipeline back to the strength of the original pipe.

Industries like oil and gas, chemical processing and power generation where high pressure systems and hazardous pipe content are present require pipe repairs to be ASME PCC-2 401-III compliant.

To qualify Sylmasta HD Pipe Repair Bandage and Industrial Metal for ASME PCC-2 401-III standard repairs, Sylmasta carried out a test independently witnessed and verified by a UKAS registered company.

The test was performed on an ASTM A106 Grade B pipe spool. This type of carbon steel pipe is often used in high temperature environments such as steam and gas lines.

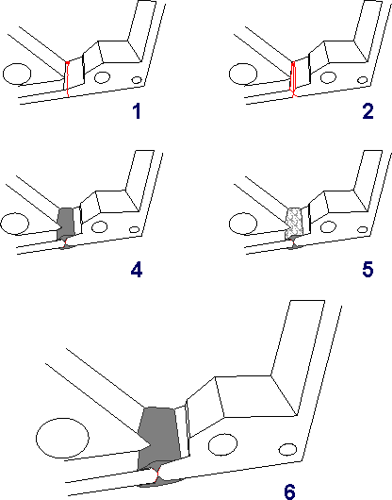

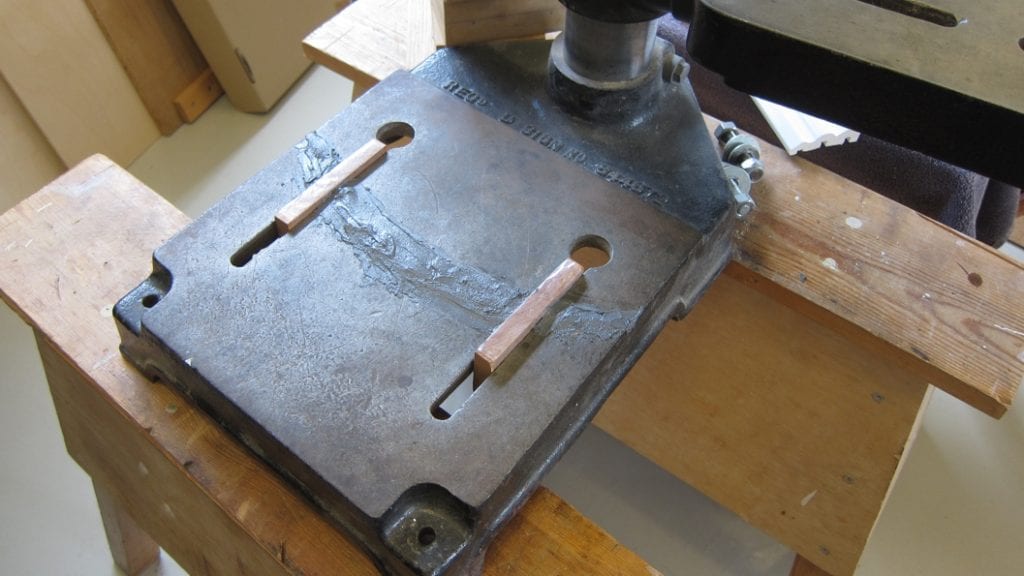

A defect was machined into the spool to reduce wall thickness down to 1mm, accounting for an 86 percent weakening of the pipe.

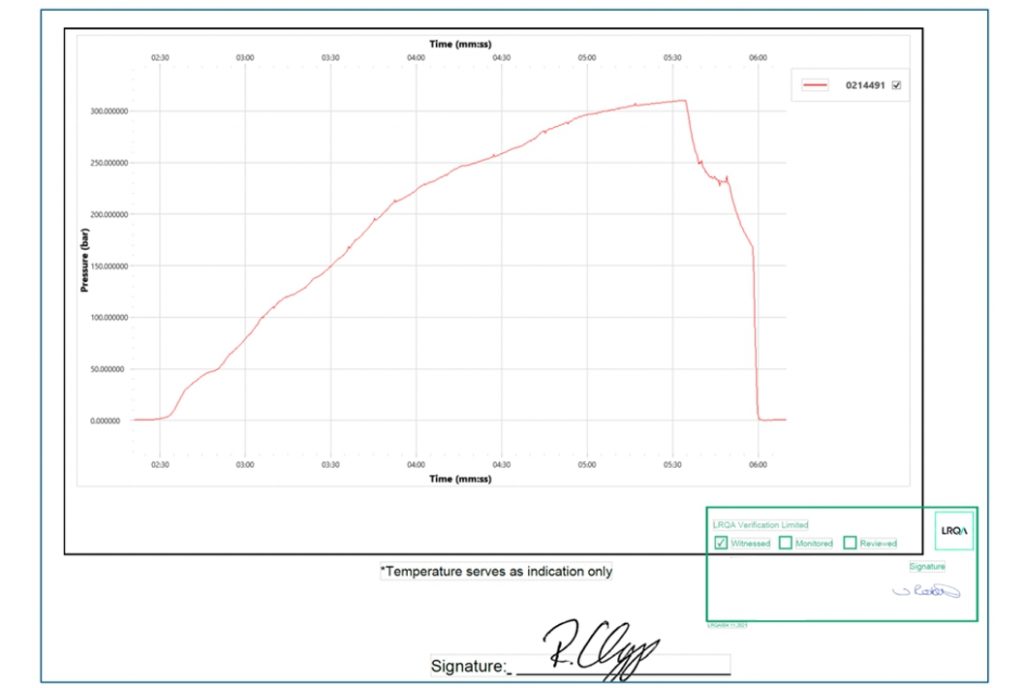

Based on the measured yield strength of the pipe, diameter and original wall thickness, the repair needed to withstand 309.6 bar of pressure to pass the test and certify the materials as PCC-2 401-III compliant.

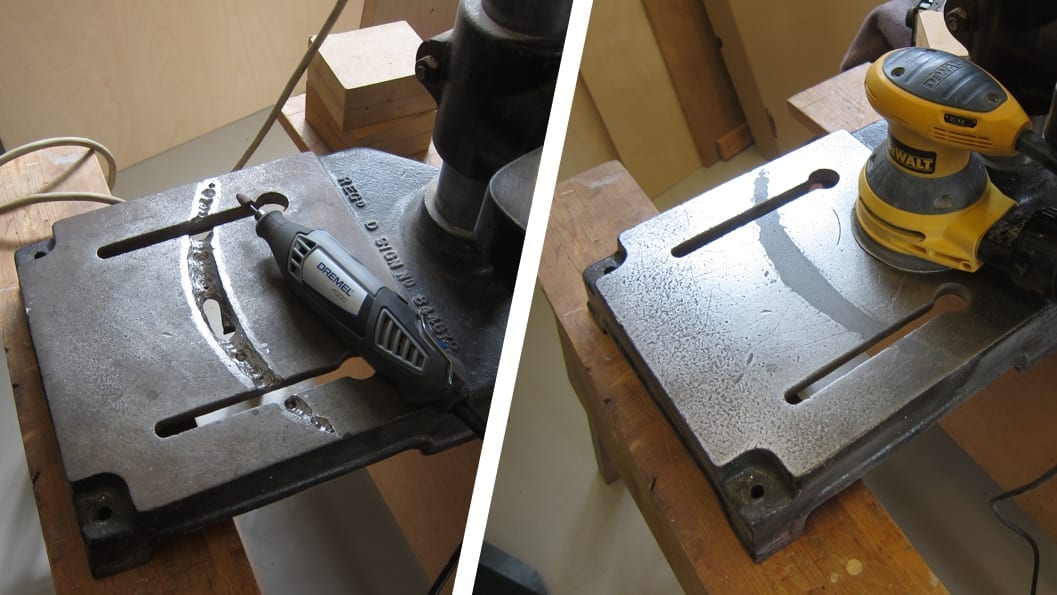

Before the repair, a flap wheel was used to clean the area back to bare metal. The whole area was then thoroughly cleaned using a solvent degreaser to remove any remaining traces of foreign substances.

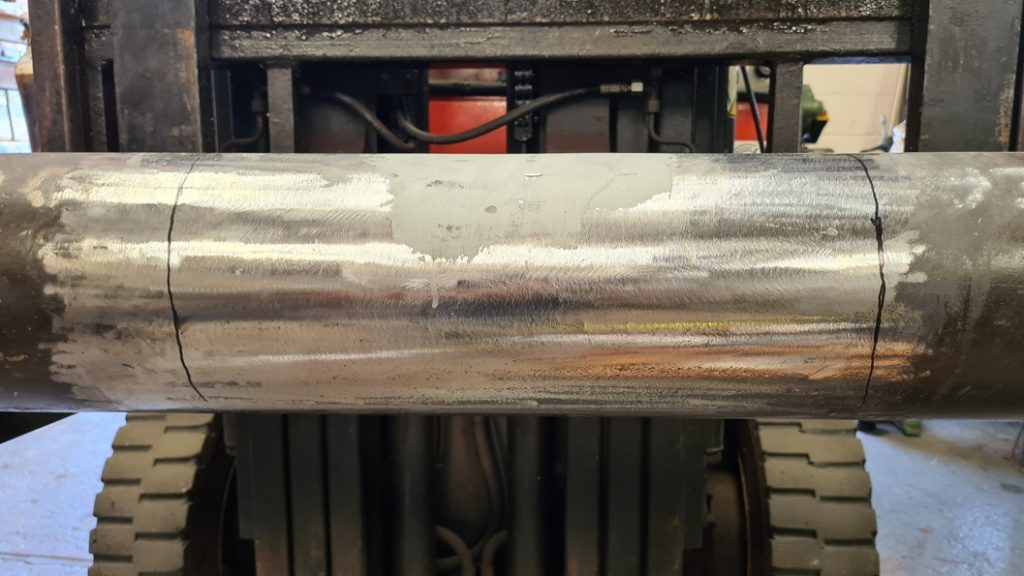

Industrial Metal Epoxy Paste was used to fill in the defect. It rebuilt the pipe wall back towards original thickness, and acted as a load transfer medium between the pipe spool and SylWrap HD.

The two parts were mixed together until turning a uniform grey colour. Industrial Metal was then applied using a putty knife, ensuring maximum contact between the spool and the epoxy paste.

Industrial Metal was allowed to fully set before the flap wheel was used to smooth the cured material and the area around surrounding it, followed by further cleaning with degreaser.

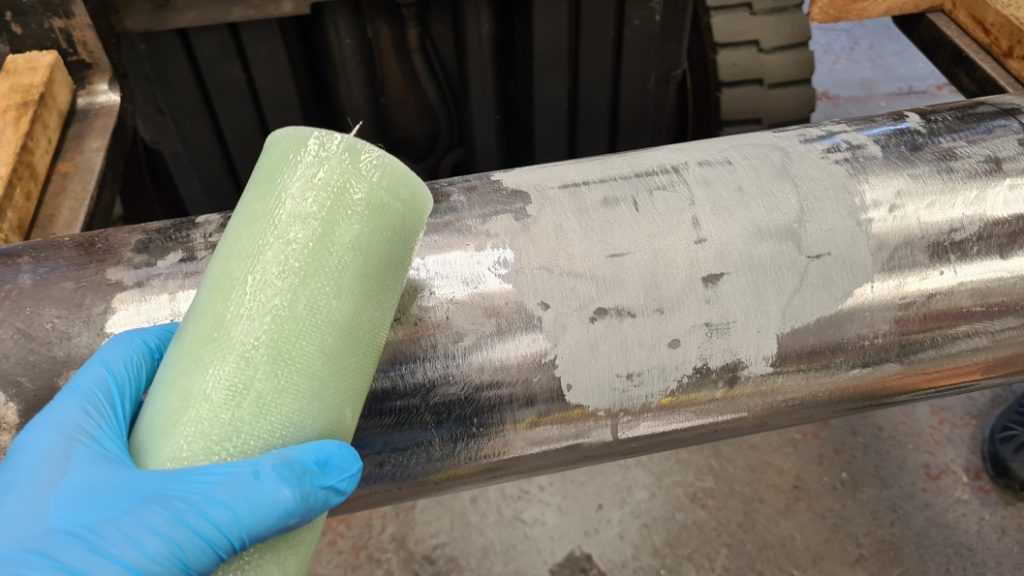

The Sylmasta Pipe Refurbishment Calculator helped determine the size and number of SylWrap HD Pipe Repair Bandage needed to reinforce the repair so it became strong enough to hold 309.6 bar pressure.

Five SYL633HD Bandages were used for the repair. The fast working, water activated resin began to cure within minutes to form a rock-hard, impact resistant shell.

Once SylWrap HD had set, the pipe spool was pressure tested by a UK-based specialist using calibrated and certified pressure gauges. The results were recorded using a data logger.

The repair exceeded the 309.6 bar required to pass PCC-2 401-III, eventually failing when pressure reached 310.29 bar and water began leaking through the edges.

With the test signed off as a success, composite pipe repairs using SylWrap HD and Industrial Metal are qualified to meet ASME PCC-2 401-III standard.

To determine the quantity of Sylmasta materials needed to make a composite pipe repair conforming to PCC-2 401-III standard, please use the ASME PCC-2 Compliant Repair Calculator below.

The calculator serves only as a guide. Judgement should be made on the exact repair based upon all conditions. Please contact Sylmasta for more information or if you need help with a specific application.

If you have an application you would like to enquire about, then please get in touch

Call: +44 (0)1444 831 459

Email: sales@sylmasta.com