You’re probably well aware of the damage that leaks can do to the value of a property and its structural integrity. Everybody notices a rise in water bills too. But arguably the most damaging aspect of leaking pipes is the one that doesn’t get talked about – the effect on human health.

When pipes start leaking, conditions suddenly become ripe for the growth of mould and mildew – two organisms which produce spores that pollute the air and can do serious damage to long-term health.

Mould and mildew

Mould and mildew are fungi which can appear anywhere. Even in newly built properties, mould spores will find a way to appear in nooks and crannies. This isn’t a problem – when left in dry areas, the organism can remain dormant for decades, never posing a threat to human health.

It’s when conditions are ripe for mould and mildew to grow and thrive that they become a real problem. For this to happen, they require air, food, the correct temperature and – crucially – moisture.

How can you prevent mould and mildew?

There’s only one realistic way that you can prevent mould and mildew, and that is by preventing access to moisture.

The other conditions that mould and mildew needs to thrive are uncontollable. Oxygen is present in every home, the organisms feed off all types of household surfaces including wood, fabric, wallpaper and paint and the optimum temperature for mould and mildew to thrive in is between 5°C and 40°C.

Keeping your home dry and ventilated is therefore the best way to combat the problem – which means fixing leaking pipes as soon as problems occur.

What damage to human health can leaking pipes cause?

Failing to repair a leaking pipe can allow moisture to gather in your home, giving mould and mildew the conditions it needs to grow.

Mildew is considered the less severe of the two organisms. It forms only on surfaces rather than within them and can be easily removed with bleach or vinegar. Its spores can cause severe allergic reactions, but it is less harmful than mould.

When exposed to moisture, mould grows quickly, producing spores in 24 hours. Unlike mildew, it penetrates surfaces rather than simply forming on the top which makes it much harder to eradicate as it will eat away at materials such as wood and drywall.

Mould’s most damaging feature though is that its spores contain allergens and irritants which cause serious health problems when inhaled from residents of visitors to properties where the organism is present.

Health issues that mould can cause include throat and skin irritation, itchy eyes, frequent coughing and sneezing as though affected by an extreme allergy, respiratory infections, breathing problems, congestion, rashes, tiredness and fever.

These problems become more severe in those with pre-existing respiratory conditions, such as asthma. Mould can even grow inside the lungs of people with severe conditions such as tuberculosis, emphysema, or advanced sarcoidosis. Children who grow up in a mould-infested house are also far more likely to develop asthma.

That’s why preventing mould and mildew from forming in the first place is so important.

How to combat the impact of leaking pipes on your health

Because mould and mildew cannot thrive without moisture, your best chance of preventing these organisms from growing and developing is to find and repair the leaking pipe which is causing the dampness.

One of the reasons that people fail to fix a leaking pipe is because they mistakenly believe that it will be a costly and timely consuming process which could involve hiring the services of a plumber.

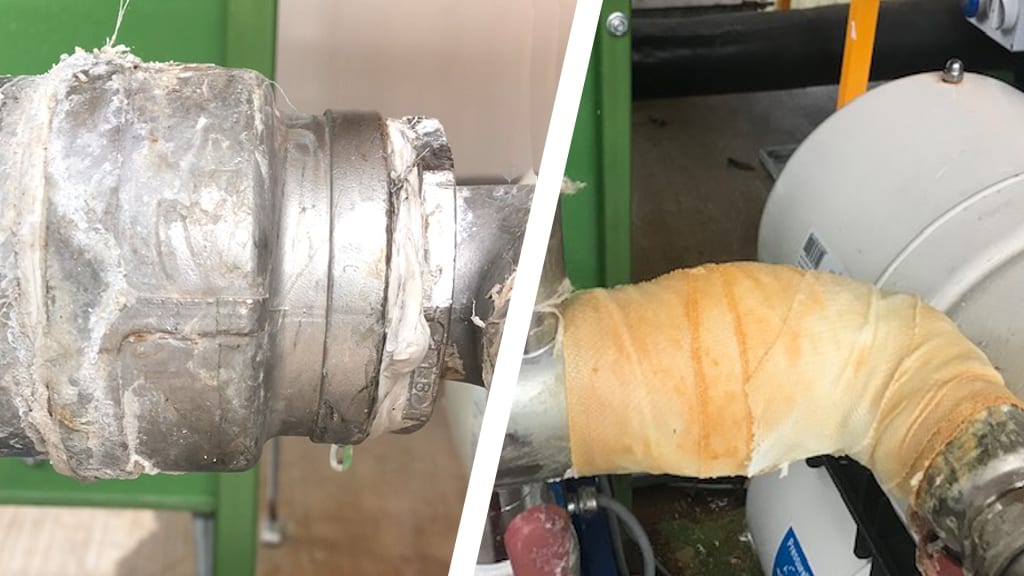

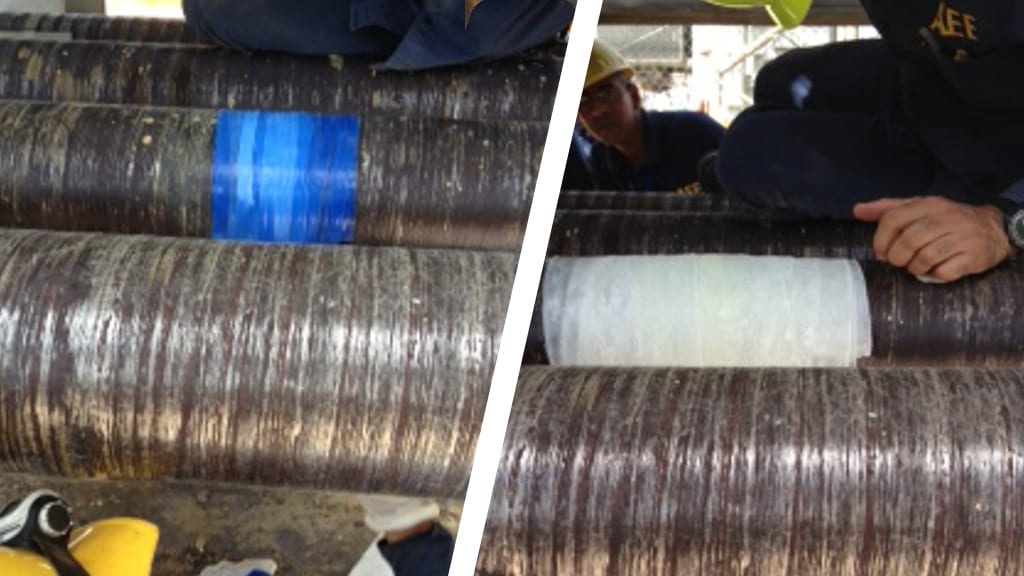

This isn’t the case, however. With a SylWrap Pipe Repair Kit, the user can permanently seal a leak inside of 30 minutes with no formal training required.

Recognising and fixing leaking pipes as soon as problems arise can prevent the growth and spread of mould and mildew, in turn helping you and your family from suffering potentially serious health complications.

It’s just another reason why pipe repair is so important.