Riding the storm – how a Sylmasta contaminated water pipe repair helped keep power going in Puerto Rico during Hurricane Maria

In 2015, a contaminated water pipe in a Puerto Rican Power Station began leaking, leaving the Power Authority in charge of the plant with two options – find a way to carry out a repair which did not require taking the pipe out of service or shutdown the generator it was connected to. Little did they know what an important decision they were taking.

Case Study Data

Site

Power Station

Location

Puerto Rico

Repair Type

Live leak pipe repair

Defect

Cracked steel contaminated water pipe

Products Used

Wrap & Seal Pipe Burst Tape

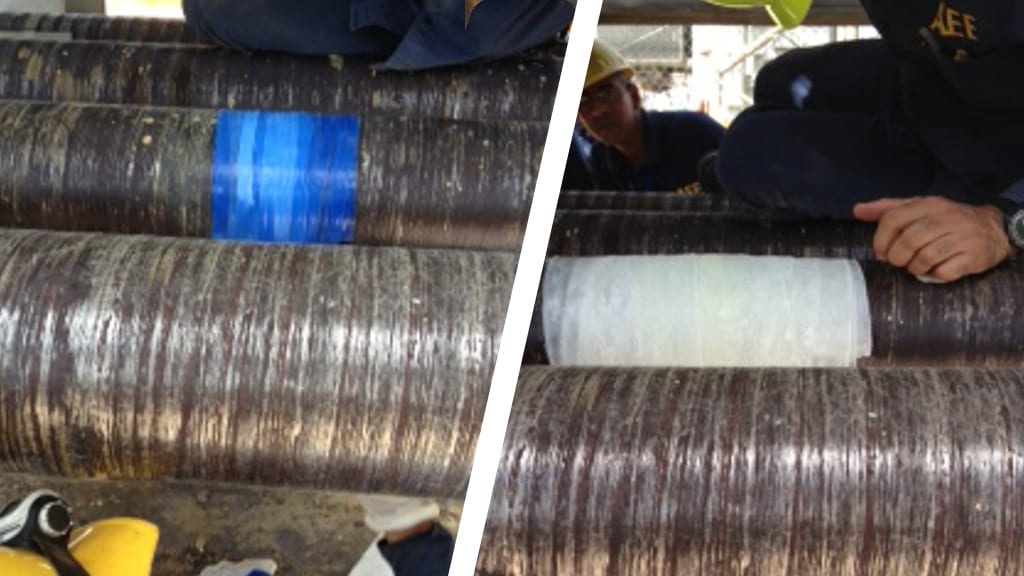

Wrap & Seal fused over the crack to provide a high pressure, temperature resistant, solid rubber band, sealing the leak

SylWrap HD Pipe Repair Bandage

The taped crack was overwrapped with SylWrap HD, reinforcing the initial repair with an impact resistant layer

SylWrap Universal Pipe Repair Kit

The products were provided as part of a Universal Pipe Repair Kit for live leaks

Case Study PDF

Case Study Review

The Puerto Rico Power Authority contacted Sylmasta to ascertain if a live leak repair to the cracked steel pipe would be possible. The SylWrap Universal Pipe Repair Kit was recommended and so the contaminated water pipe was easily repaired.

Which was just as well. Within 18 months, Puerto Rico needed all the power generating capability it could muster after the most devastating natural disaster in the recorded history of the island.

The damaged steel pipe was responsible for running contaminated water from a generator in the Power Station back to a treatment plant. At some point, a crack had developed in the bottom of the pipe, through which contaminated water was now escaping.

Nobody was sure how the pipe had been damaged. It was thought that equipment which had been stored underneath the pipe may have inadvertently impacted on it when it was moved shortly before the leak was noticed.

For the Power Authority to make a repair with water pressure turned off or replace the leaking pipe, the generator which was connected to the pipe would have needed to be shutdown. This would have been expensive and severely reduced the Power Station’s capacity for generating electricity.

There was also the danger that once taken out of the service, the repair could have taken a significant amount of time owing to the complications of getting parts shipped to Puerto Rico and flying in contractors to carry out the work. If all of this turned out to be too time consuming and costly, then the generator may have remained out of service.

Thanks to a Universal Pipe Repair Kit, it did not come to that. Wrap & Seal Pipe Burst Tape was applied to the pipe to seal the crack. The waterproof repair tape stretches by 300% and is twice the thickness of any other self-fusing pipe repair tape, ensuring that it fixes leaking pipes even when pressure cannot be turned off.

A SylWrap HD Pipe Repair Bandage was then applied over the Wrap & Seal. SylWrap HD set rock hard inside 30 minutes, providing an impact resistant layer and turning the repair permanent. Within an hour, the contaminated water pipe repair was completed, the generator was put back into service and the Power Plant was producing electricity at full capacity again.

The true value of the repair became apparent in 2017, when the category five storm Hurricane Maria hit Puerto Rico, Dominica and the U.S. Virgin Islands. It was the deadliest Atlantic hurricane for nine years and left a trail of destruction in its wake across the Caribbean.

Central to the relief efforts both during and after Hurricane Maria was keeping the power on in Puerto Rico. Six months after Hurricane Maria, the contractor who fixed the contaminated water pipe got in contact to say that without the Sylmasta repair of the contaminated water pipe, the Power Station would have had one less generator at a time when Puerto Rico needed all the power available to it.

As a result, the Power Authority were extremely grateful that such a quick and easy repair had been possible. They have since started using the contaminated water pipe case study as an example of why industry should seek repair solutions as soon as problems arise.

If you have an application you would like to enquire about, then please get in touch

Call: +44 (0)1444 831 459

Email: sales@sylmasta.com