Ceramic Brushable Blue helps a landscaping materials supplier lay a path to metal pallets protection

A landscaping materials company use Ceramic Brushable Epoxy Coating to repair and protect metal pallets at their central warehouse left damaged by years of having heavy and abrasive items like driveway paving, garden slabs and natural stones stacked on them.

Case Study Data

Site

Landscaping materials supplier warehouse

Location

United Kingdom

Repair Type

Metal repair and protection

Defect

Metal pallets damaged and worn by storage of abrasive, heavy materials

Products Used

Ceramic Brushable Epoxy Coating

Epoxy coating reinforced with silicon-carbide which protects metal surfaces against wear, abrasion and impact

Case Study PDF

Case Study Details

As one of the biggest suppliers of landscaping materials in the United Kingdom, the company had a vast central warehouse storing items which were then sent to distributors around the country.

These materials included driveway paving, garden slabs, kerbs, edges, porcelain, natural stone and bricks. All were stacked and stored on metal pallets.

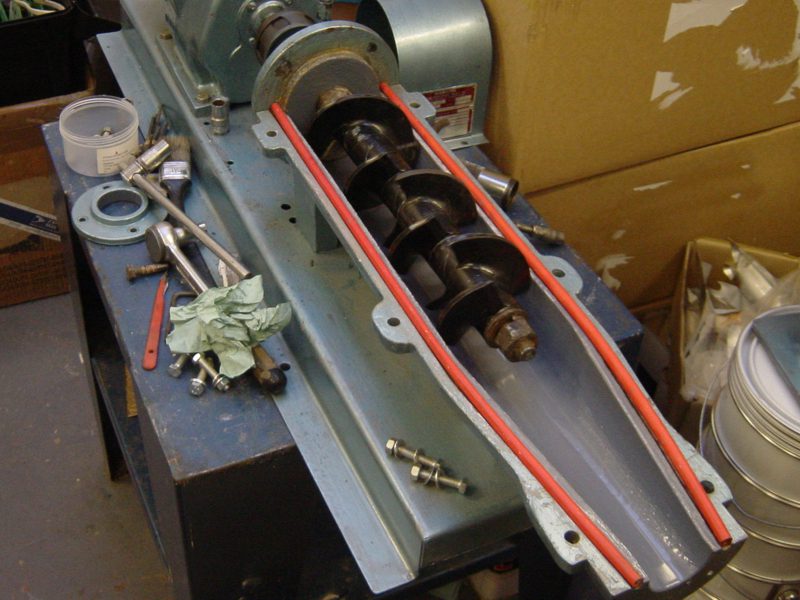

The weight of these materials, their abrasive nature and the impact from moving them on and off the metal pallets meant that over time, the metalwork began to show visible signs of wear.

Removing all existing pallets from the warehouse and installing replacements would have been a time-consuming and expensive task.

The landscaping company therefore contacted a mechanical engineering specialist who used and distributed Sylmasta products for advice. They suggested Ceramic Brushable Blue Epoxy Coating to repair the metal pallets in the warehouse.

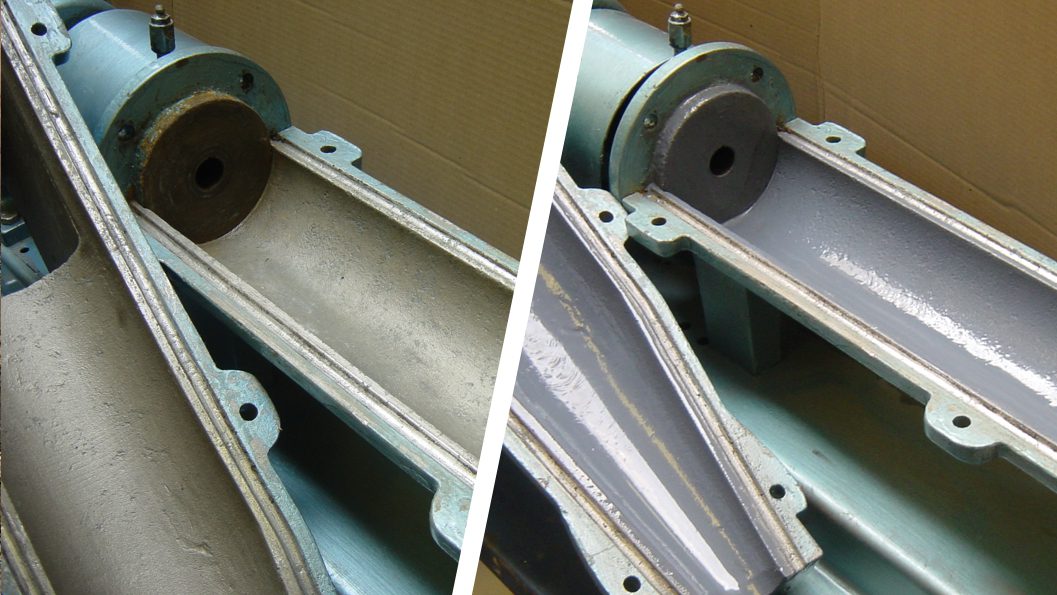

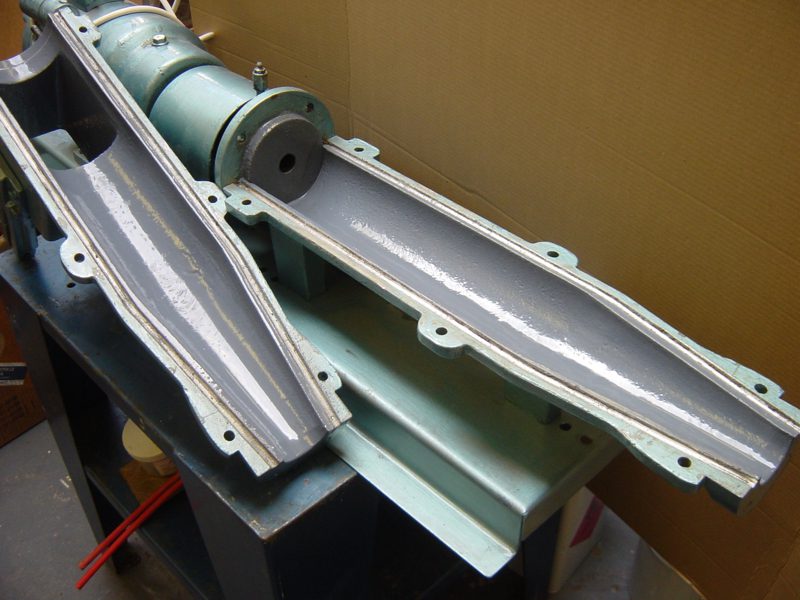

Ceramic Brushable is reinforced with silicon-carbide for hardness and an ultra-smooth finish. It is painted onto parts and surfaces to create an outer layer with extreme resistance to abrasion, corrosion, chemical attack, cavitation, erosion and pitting.

Two coatings of Ceramic Brushable were applied to the top part of the pallets which the landscaping materials sat on. It cured to form a hardened shell, protecting the original metalwork against abrasion and impact damage caused by the materials.

Initially, only a few pallets were treated as a trial run to test the performance of Ceramic Brushable. Six months later and there were no visible signs of damage to any of the coatings applied during the trial.

Satisfied with the performance of Ceramic Brushable, the landscaping company purchased 10kg to repair and protect more metal pallets throughout the warehouse.

They are also now considering opting for a two-layer wear indicator coating, whereby a topcoat of Ceramic Brushable Green or Black is applied over the existing Blue.

When the Blue layer begins to show through, it will indicate a new topcoat of Green or Black is required to maintain suitable protection levels for the pallet.

Having a clear system showing when to reapply Ceramic Brushable will help the company continually extend the lifespan of its metal pallets for years to come.

If you have an application you would like to enquire about, then please get in touch

Call: +44 (0)1444 831 459

Email: sales@sylmasta.com