Description

SylPad is used in conjunction with Wrap & Seal Pipe Burst Tape to increase pressure resistance during live leak repairs of holes up to 20mm on pipework in excess of 150mm diameter.

It is placed over the hole being sealed during the application of the two largest sizes of Wrap & Seal (PB-50x4HD and PB-50x11HD), where it will stick to the tape without the need for any adhesive.

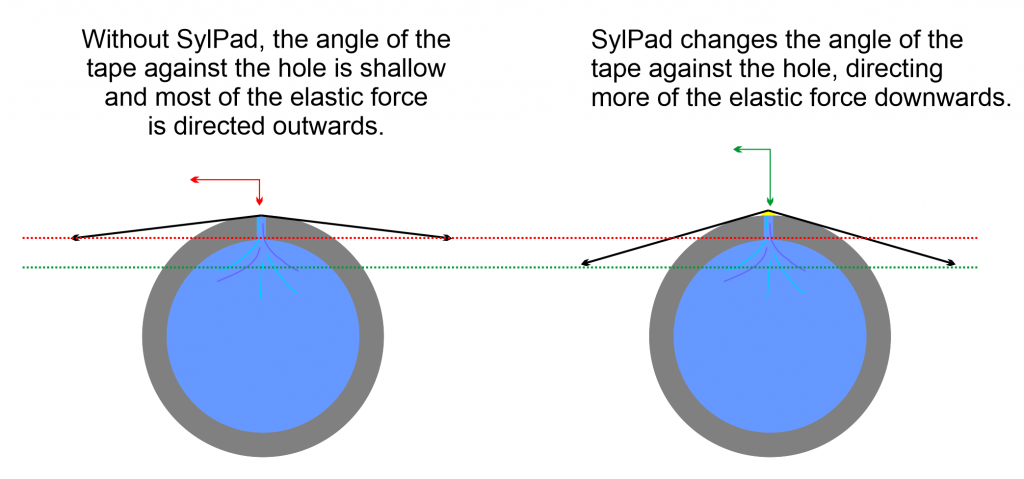

As layers of Wrap & Seal are wrapped around the pipe, SylPad changes the angle of the tape against the hole to better concentrate elastic force directly over the leak.

Depending on pipe diameter, the nature of the leak and quality of the repair, SylPad can increase the pressure resistance of Wrap & Seal by up to three times.

This makes the tape more effective, reduces the number of Wrap & Seal required to reach high pressure resistance and speeds up repait time.

How to use SylPad to increase live leak repair pressure resistance

SylPad is only used on pipework over 150mm diameter, where changing the angle of Wrap & Seal is beneficial.

The repair area is first marked with a horizontal line drawn by a pen, so the exact location of the hole is still identifiable after application of the tape.

Wrap & Seal is then anchored 50mm to the side of the leak, before being wrapped towards the hole with a 50 percent overlay. Once the leak is reached, the tape is wrapped directly over it to build up layers.

After two layers, SylPad is pushed onto Wrap & Seal covering the exact location of the hole as marked by the pen. SylPad will stick straight onto the tape.

Application of Wrap & Seal then continues over the leak, leaving the SylPad secured in place and cocooned between layers. Greater pressure resistance is now directed over the live leak rather than spread outwards.

If water is still seeping from the pipe once one Wrap & Seal has finished, additional tapes are applied until the leak is completely sealed. It is possible to use multiple Wrap & Seal fused together to build resistance up to 30 bar.

Once the user is satisfied the leak has stopped, a SylWrap Pipe Repair Bandage should be applied to protect and reinforce the repair.

Because SylPad is contained within Wrap & Seal and does not come into contact with pipe fluid, it does not require WRAS approval for use with potable water.

SylPad is included as standard in SylWrap Universal Pipe Repair Kits 633 and 866 and all SylWrap Pipe Repair Contractor Cases covering pipework 150mm upwards.

The Universal Pipe Repair Kit and Contractor Cases also contain Wrap & Seal, Superfast Epoxy Putty and SylWrap Bandage for making permanent, live leak pipe repairs.

Benefits of a SylPad Pressure Resistance Multiplier

- Designed for use with Wrap & Seal, adhering directly to the tape for ease of application

- Increases pressure resistance of repair, speeding up application time and reducing number of tapes requires

- Quick and easy to use – repairs can be made in under 30 minutes

Applications

- Repairs to pipes in excess of 150mm diameter where pressure cannot be turned off

- Sealing high pressure live leaks on water networks

- Industrial live leak repairs, including wastewater treatment works, quarry wash plants, dry risers, petrochemical plants, nuclear power plants, oil rigs, farms, hotels, and breweries