Cool engine heat exchange repair keeps a narrowboat sailing

A narrowboat owner uses Superfast Titanium Epoxy Putty Stick to make a high temperature repair to a 15mm x 15mm hole which appeared in the engine heat exchanger manifold of the vessel.

Case Study Data

Site

Narrowboat

Location

United Kingdom

Repair Type

Heat exchanger manifold repair

Defect

15mm x 15mm hole

Products Used

Superfast Titanium Epoxy Putty

Epoxy putty resistant to 280°C for making repairs to high temperature systems, equipment and parts

Case Study PDF

Case Study Details

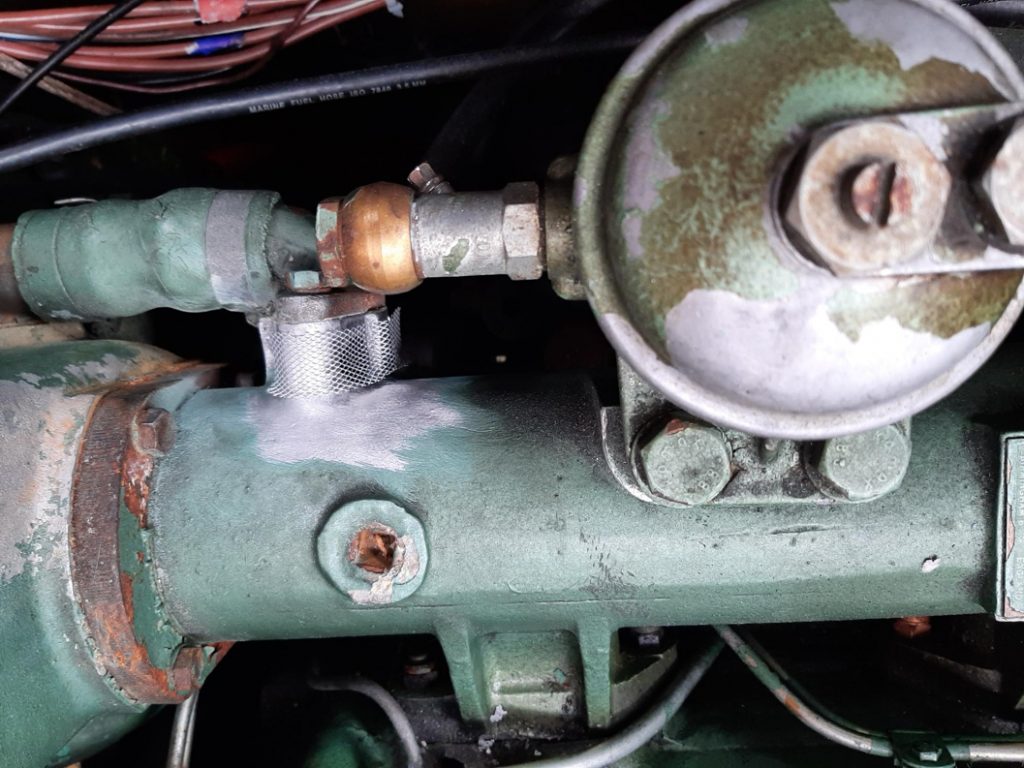

The narrowboat had a raw water system for cooling the engine, including a manifold mounted heat exchanger. It worked by pumping canal water into a tank containing a series of pipes on the exhaust manifold.

Inside these pipes ran engine coolant, circulated around the engine block by another pump. The canal water in the tank passed over the pipes, cooling the engine coolant in the same way a fan does in a car. The water was then expelled through the exhaust.

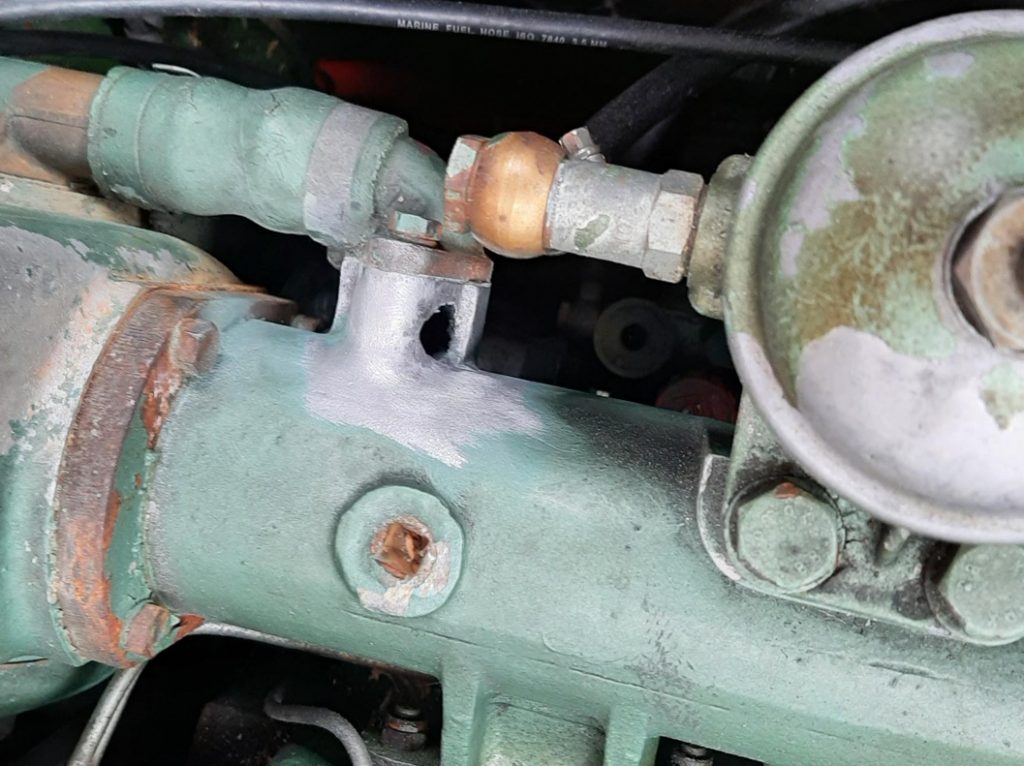

The narrowboat was moored on a canal in Hertfordshire, around 30 miles north of London, when the owner discovered a 15mm x 15mm hole had appeared in the heat exchanger manifold.

They decided to repair the manifold using Superfast Titanium Epoxy Putty Stick. Superfast Titanium was selected because of its high temperature resistance, enabling it to withstand up to 280°C.

Within 24 hours of the narrowboat owner contacting Sylmasta, Superfast Titanium had been delivered to a collection point close to where the vessel was moored.

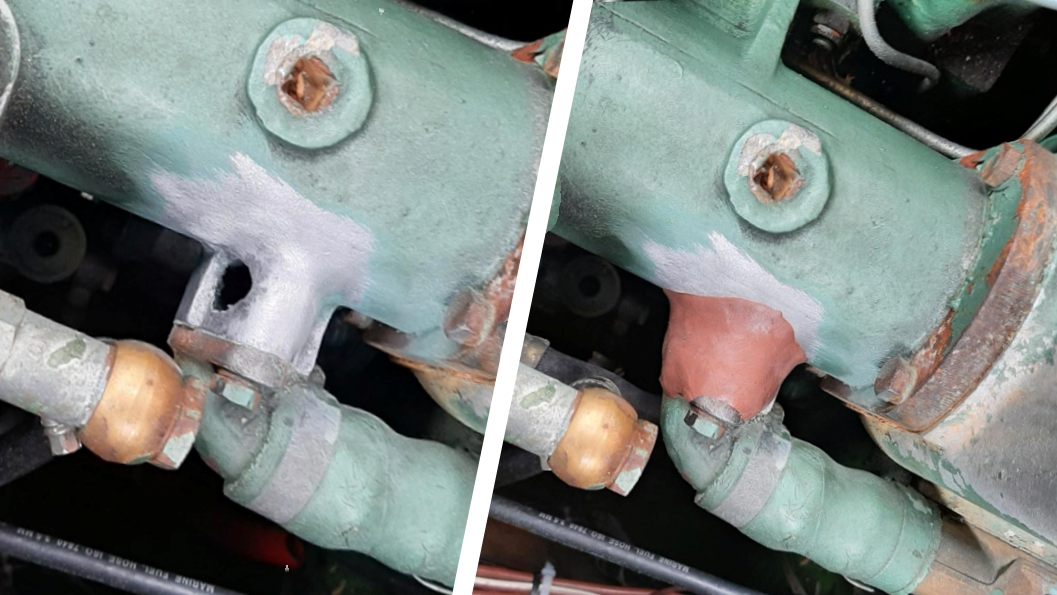

Before the repair, the narrowboat owner cleaned and rubbed down the heat exchanger manifold to improve adhesion with the epoxy putty. Aluminium mesh was placed over the hole as a precautionary measure to prevent any epoxy putty entering the manifold exchanger.

Enough Superfast Titanium to cover the hole was then cut from the stick and kneaded by hand until it turned a uniform, golden brown colour to indicate successful mixing.

The putty was applied over the mesh and surrounding area. It was pushed firmly onto the manifold to ensure maximum contact before being smoothed off with a little water.

Superfast Titanium has a work time of 90 minutes. It reached working strength in eight hours and achieved a full cure after 72 hours.

The narrowboat engine could have gone back into service after eight hours, but the owner was in no rush to set sail again and so remained moored for the full cure time.

If you have an application you would like to enquire about, then please get in touch

Call: +44 (0)1444 831 459

Email: sales@sylmasta.com