Productivity improved at power plant as corrosion protection for heat exchanger removes annual repair requirement

Having spent many years annually reapplying a standard epoxy coating to the inside of a heat exchanger plenum chamber, a power plant in Thailand seek a more robust corrosion protection method to improve system efficiency and reduce downtime.

Case Study Data

Site

Power plant

Location

Thailand

Repair Type

Corrosion protection

Defect

Heavily corroded metalwork and parts inside heat exchanger plenum chamber

Products Used

Liquid Metal Epoxy Coating

Brush applied coating which cures to a hard wearing, metallic layer protecting surfaces and parts against corrosion

Case Study PDF

Case Study Details

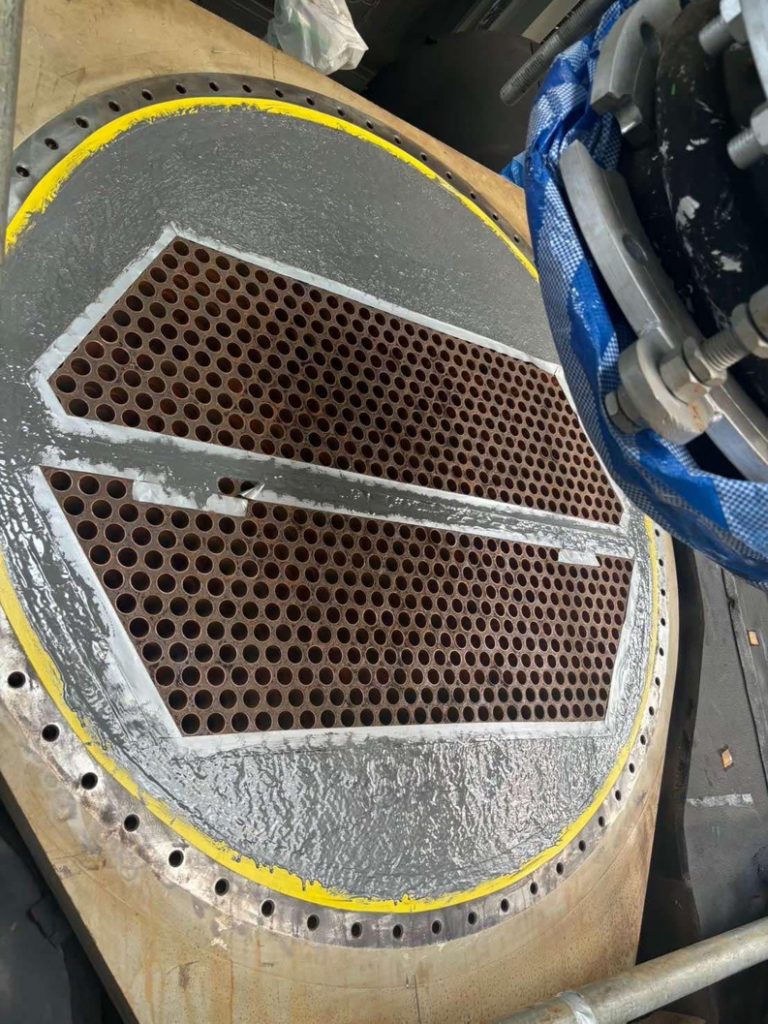

A plenum chamber – sometimes known as a water box – is found at the end of a heat exchanger. It supplies and directs the flow of water through the tubes of the heat exchanger.

Conditions inside a plenum chamber are perfect for galvanic corrosion and cavitation. Extreme temperatures, high pressure and unpurified water passing through the box leave the metalwork under constant attack and requiring frequent repair.

The power plant had spent many years using a standard epoxy coating to protect the plenum chamber. The rate of corrosion meant a new coating had to be applied annually.

This involved shutting down the system, disassembling the heat exchanger, applying the coating and then putting it all back together. It was a disruptive process which resulted in significant downtime for the plant.

It was therefore decided to find a more robust, effective coating to protect the plenum chamber which did not require yearly reapplication. The plant analysed conditions inside the water box and came up with a specification for their ideal epoxy coating.

Temperature resistance had to be as a high as 149°C with long-term performance at operational temperatures of 25–40°C. It needed to be resistant to pH 8-10 and pressure up to 3 bar. Most importantly, the plant wanted a coating strong enough to last several years at least.

Taking these requirements into consideration, Sylmasta recommended using Liquid Metal Epoxy Coating to protect the inside of the plenum chamber, the tubes within the water box and its condenser faceplate.

Liquid Metal is metal-filled, meaning it offers superior corrosion resistance and enhanced durability by creating a thicker, more resilient layer. The cured material has Shore D hardness in excess of 80 and a maximum service temperature of 150°C.

Before application, the metal surface was thoroughly cleaned to remove rust, other contaminants and any traces of the previously applied standard epoxy coatings.

Liquid Metal was then painted onto the areas requiring protection using a brush. Three coatings 1mm thick were applied. Liquid Metal has a 90-minute gel and a four hour re-coat time. The entire repair was completed over two days.

Once the final coating had cured, the original metalwork inside the heat exchanger plenum chamber, tubes and the condenser faceplate were covered with a 3mm thick metallic layer, offering ultimate protection against corrosion and cavitation.

Six months after the repair, the manager of the engineering company responsible for maintenance at the plant contacted Sylmasta with an update.

“I had a good experience with Liquid Metal. We have looked at the heat exchanger and condenser again and the coating has fully performed and protected from corrosion very well.”

“We now want to use Liquid Metal on 22 blowdown tanks at this plant and more systems at other power plants in Thailand where we run maintenance.”

If you have an application you would like to enquire about, then please get in touch

Call: +44 (0)1444 831 459

Email: sales@sylmasta.com