Sylmasta supply pipe repair and maintenance solutions for infrastructure operators, utility suppliers, multinational corporations and government departments as well as small businesses and individuals worldwide – the case studies section of our website showcases some of the projects that Sylmasta have been involved in.

If you have any questions about any of the solutions supplied by Sylmasta or require help with an application of your own, then please contact us and a technician will be happy to assist you.

Case Studies by Type

Latest Case Studies

Case Study: Underground 600mm Concrete Water Pipe Break Repair in Canada

A city authority in Canada repair a break in an underground 600mm diameter concrete pipe at the point it passed through a wall, significantly reducing levels of water loss

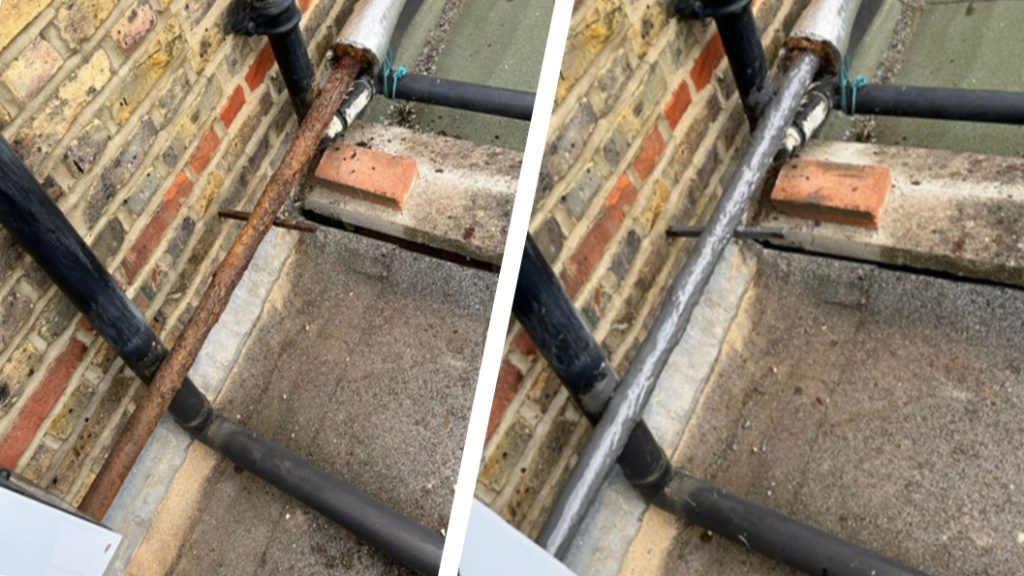

Case Study: Repair of 1.05-Metre Long Crack in Cast Iron Downpipe at UK Hospital

A 1.05-metre long crack in a cast iron downpipe leaking rainwater into a wall cavity at a hospital is repaired in under 30 minutes with no disruption to patients and staff

Case Study: Rotted Wooden Beam Repair in Home Renovation Project

Large voids in a rotted wooden beam are filled to create a flat, smooth surface enabling the outside of a house to be rendered as part of a renovation project

Case Study: Pipe Joints Sealed in Cast Iron Rainwater Stack Repair at London Office Block

300 pipe joints left leaking by corrosion in an internal cast iron rainwater stack are sealed, avoiding a total system replacement during the refurbishment of an office block

Case Study: Corrosion Protection of 600mm Ductile Pipe & Outlets in Underground Pumping Station

Corrosion protection measures are made to a ductile pipe system including three outlets and six flanges in an underground pumping station operated by a UK water company

Case Study: Alcohol Line Live Leak Pipe Repair at Sugar Mill in Costa Rica

A sugar mill in Costa Rica seal a 70mm pipe running vertically up a tower after alcohol juice extracted during cane fermentation was found spraying out a pinhole

Case Study: Repair of Leaking & Corroded Shared Water Supplying Eight Cottages

Four cottages in a terrace of eight repair their respective sections of a leaking and corroded 48 metre long shared water supply pipe attached to the back wall of the properties

Case Study: Luxury Portable Toilet Trailer Leaking Wastewater Holding Tank Repair

Wastewater holding tanks underneath two luxury portable toilet trailers undergo repair and strengthening after heavy corrosion weakened and breached the metalwork

Case Study: Reassembly & Repair of Composite Stone Water Fountain Cracked into Pieces

The upper bowl of a tiered composite stone water fountain which cracked into multiple pieces during freezing winter weather is reassembled and repaired by its owner

Case Study: Repair of Hairline Crack Around Diameter of Porcelain Toilet Soil Pipe

A homeowner repairs a porcelain soil pipe with a hairline crack around its diameter caused by a toilet moving away from the wall it was connected with

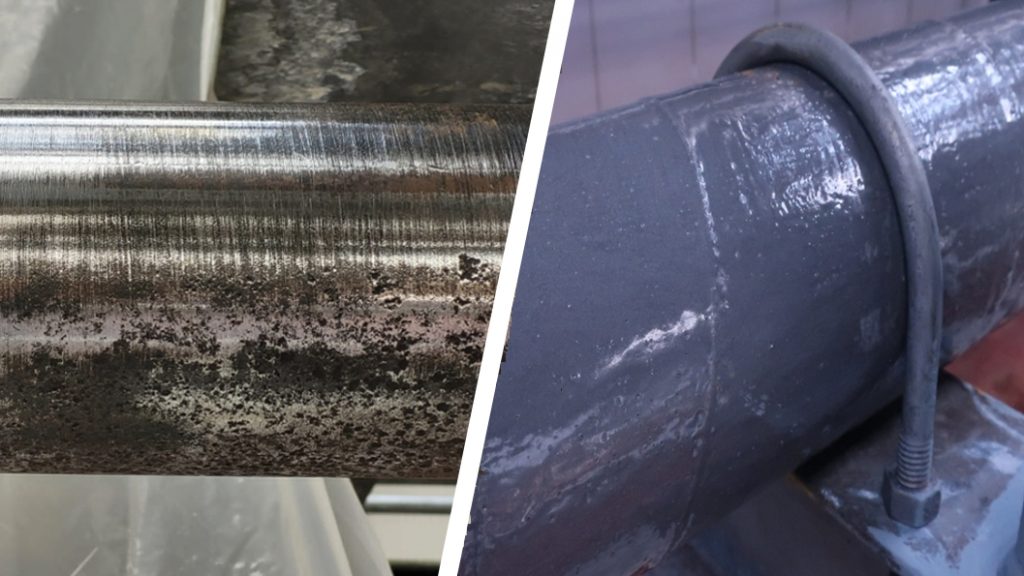

Case Study: 3 Metre Section of Corroded Steel Gas Pipe in CHP System Repair & Refurbishment

A pipe carrying natural gas in a combined heat and power system is refurbished after water trapped between the line and a badly installed PVC tape caused heavy corrosion

Case Study: Leaking Welded Saddle Joint Repair on 150mm Steel Pipe at Pumping House

A leaking saddle joint welded on a 150mm steel pipe at a pumping house in Malaysia is sealed by building a repair up and over a 20mm step between the line and the joint

Case Study: Burst Copper Pipe Repair in Portable Horse & Dog Shower Unit

Copper pipes in horse and dog showers which burst when temperatures in the UK went as low as -15°C are repaired, returning the units to service in under 30 minutes

Case Study: Seawater Storage Tank Floor Repair at Gas Processing Plant in Saudi Arabia

Gaps between rubber sheets covering the floor of a seawater storage tank at a gas plant are filled in to protect the exposed concrete coating the bottom of the tank

Case Study: Live Leak Repair of 150mm Cement Coated Steel Pipe on Water Network in Mexico

A live leak repair is made to an underground cement coated steel pipe supplying potable water in Mexico after removal of the outer shell revealed a 80mm split in the line