No replacement parts, no problem – repair and refurbishment keeps historic Worthington Simpson Pump operational

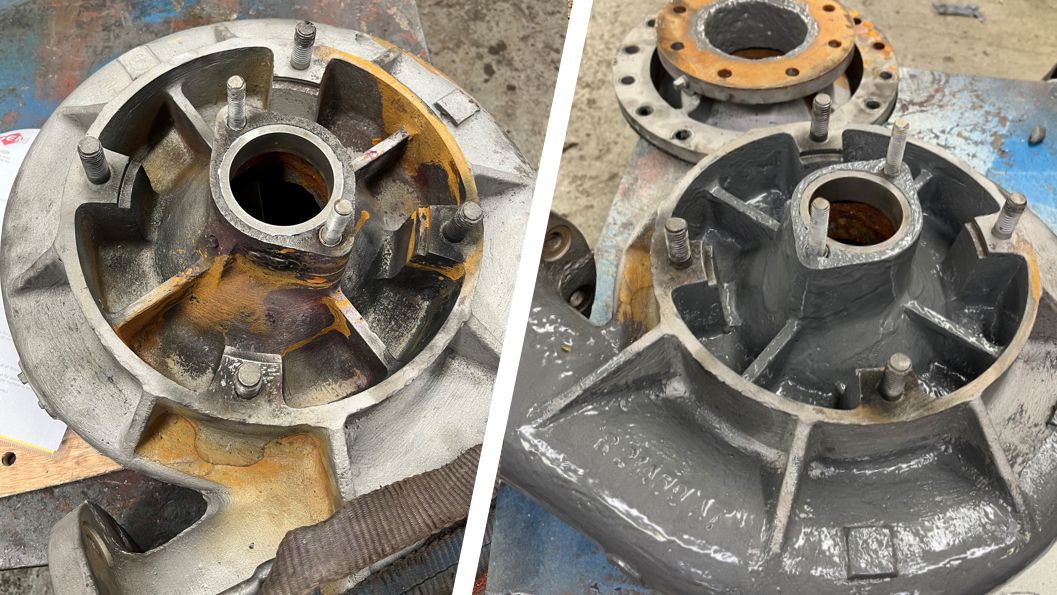

The inside of a Worthington Simpson pump head – old enough that replacement parts no longer exist – undergoes repair after the removal of corrosion via shot-blasting left multiple pinhole leaks in the casing.

Case Study Data

Site

Engineering company

Location

Warwickshire, UK

Repair Type

Pump repair

Defect

Pinhole leaks in heavily corroded Worthington Simpson pump head casing

Products Used

Superfast Steel Epoxy Putty Stick

Fast working epoxy putty which cures within 10 minutes for quickly sealing small holes and leaks in metalwork

Liquid Metal Epoxy Coating

Brush applied coating forms a robust metallic surface when painted onto parts and surfaces to shield against corrosion

Case Study PDF

Case Study Details

Worthington Simpson were a British pump manufacturer founded in 1785. They operated independently until merging in 1967 with American companies Wagner Electric and Studebaker Corporation, becoming a subsidiary of Studebaker-Worthington.

In their heyday, Worthington Simpson supplied pumps for most municipal waterworks throughout Great Britain. They later worked with the Royal Air Force and the Royal Navy.

The demise of Worthington Simpson has made getting hold of replacement parts for older pumps virtually impossible. Repair and refurbishment is therefore the only option to keep systems operational.

GEM Integrated Solutions are an electrical and mechanical engineering company in the United Kingdom specialising in motor and pump repair.

They were asked by the owner of a now-obsolete Worthington Simpson pump to refurbish the corroded pump head, for which spare parts no longer exist.

The pump was disassembled so that the inside of the head could be shot-blasted to remove all traces of rust, dirt and grime. But when the pump was then pressure tested after the repair, it was found to be leaking.

Shot-blasting had turned the head porous by creating several pinholes in the casing, through which water sprayed out in small volumes when the pump was pressurised. This was not something which GEM had experienced before.

An attempt to patch weld over a pinhole was unsuccessful, leaving GEM needing an alternative method to seal the casing and successfully complete the Worthington Simpson pump repair for their client.

They used two 114g Superfast Steel Epoxy Putty Sticks to fill all pinholes in the pump. Small amounts of epoxy putty were cut from the stick, mixed by hand and then pushed flat onto the casing over every pinhole.

Within 10 minutes of application, Superfast Steel cured to form a rock-hard material covering all leaks. No water could now escape the pump.

Liquid Metal Epoxy Coating was then used to completely seal the casing and give the metalwork inside robust protection against future corrosion, extending the lifespan of the pump.

Three coatings of Liquid Metal were painted onto the casing. Once cured, this provided a 3mm thick reinforced metallic layer which covered the pump interior.

Fluid inside the pump was now fully contained and with the original metalwork shielded from water contact by Liquid Metal, it will now be many years before the inside casing shows any sign of corrosion again – much to the delight of the client.

If you have an application you would like to enquire about, then please get in touch

Call: +44 (0)1444 831 459

Email: sales@sylmasta.com