Keeping the light on at Christmas – Superfast Aluminium and the outdoor projector repair

Superfast Aluminium Epoxy Putty saves Christmas for one British family by enabling the quick and easy repair of a broken outdoor light projector fitting, ensuring the festive show could go on.

Case Study Data

Site

Domestic home

Location

UK

Repair Type

Plastic repair

Defect

Broken fitting for outdoor Christmas light projector

Products Used

Superfast Aluminium Epoxy Putty

Fast working epoxy putty which permanently bonds broken parts back together in under 10 minutes

Case Study PDF

Case Study Details

The Christmas light projector projected festive scenes of joy and happiness onto the outside wall of a house in the United Kingdom via a relatively simple setup.

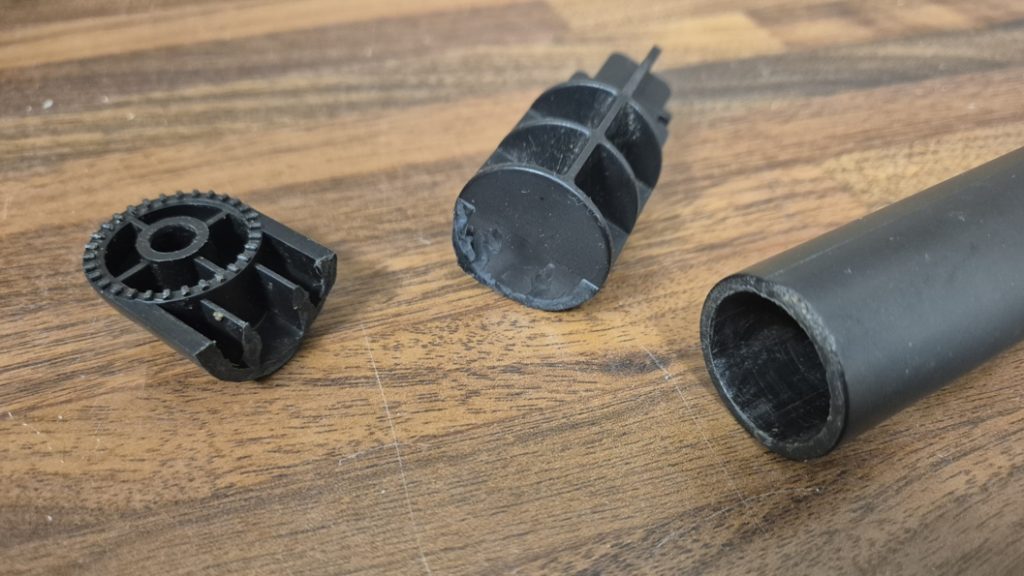

A spike was stuck into the ground where the projector was to be positioned. The projector then slid into the spike and was fixed in place by a fitting.

One day, the family returned home to find the projector detached from the spike and the fitting had snapped into two pieces. The family believed there were two possible causes; either accidental damage or one of the neighbouring allotment holders channelling their inner Ebenezer Scrooge.

Whether accident or deliberate sabotage, no decorative light show meant Christmas would have to be cancelled with much wailing and gnashing of teeth – unless the fitting could be repaired.

Thankfully, no wise men nor Christmas miracle were needed. Just Superfast Aluminium Epoxy Putty Stick to permanently bond the fitting back to together.

Superfast Aluminium is a fast-working epoxy putty. Although it is formulated for the repair of aluminium, other alloys and metals, it can also bond to many plastics. It was shaped in this application to hold the parts together mechanically.

Enough putty was cut from the stick and kneaded by hand until it turned a uniform silver colour. Whilst soft, it was used to reassemble the pieces of the fitting.

Within 10 minutes, Superfast Aluminium had hardened to form a cohesive bond holding the fitting back together. More epoxy putty was then mixed and applied as a ring around the entire break area, reinforcing the repair and giving it added strength. Just in case Scrooge returned.

The outer ring was left for one hour to reach a full cure before the fitting was placed back in the spike in the ground. The projector light was then turned back on, leaving the repair to be hailed a success and Christmas saved for the family.

If you have an application you would like to enquire about, then please get in touch

Call: +44 (0)1444 831 459

Email: sales@sylmasta.com