Description

Ceramic Brushable is a ceramic-filled, abrasion resistant epoxy coating reinforced with silicon carbide which is brush applied to protect and seal metal, plastic and wood surfaces.

The silicon carbide gives the cured material extreme hardness, high resistance to abrasion and an ultra-smooth finish.

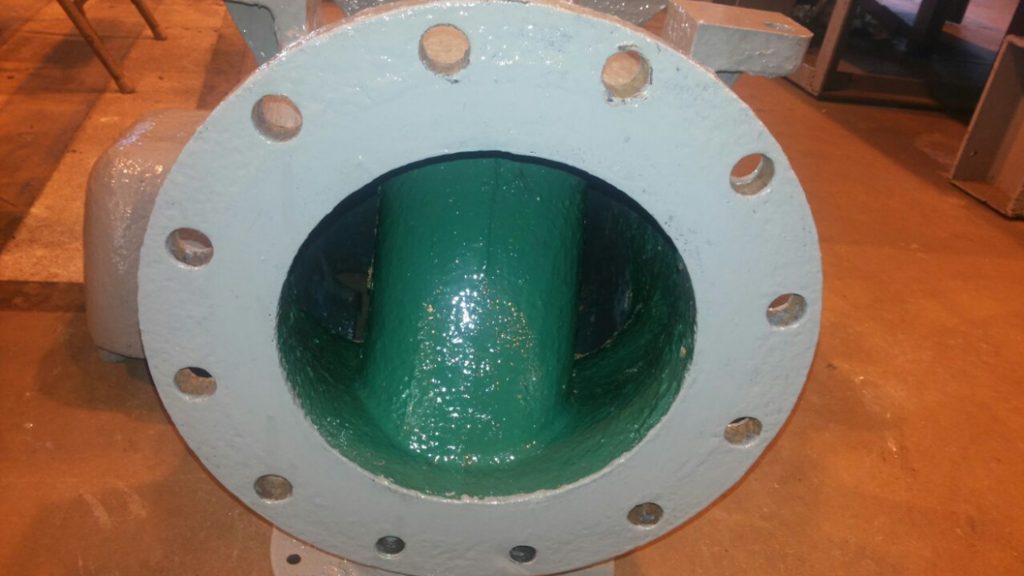

It also provides excellent protection against corrosion, chemical attack, cavitation, erosion and pitting.

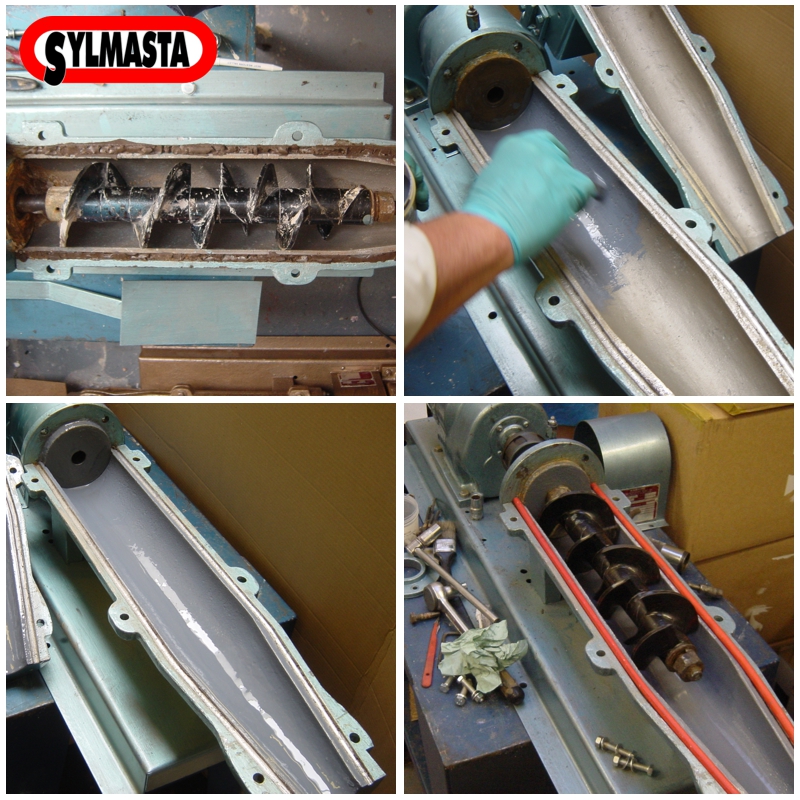

Ceramic Brushable is typically used to repair heavy damage to silos, mills, pumps, metal castings, tanks and other machine parts and surfaces in highly abrasive industries.

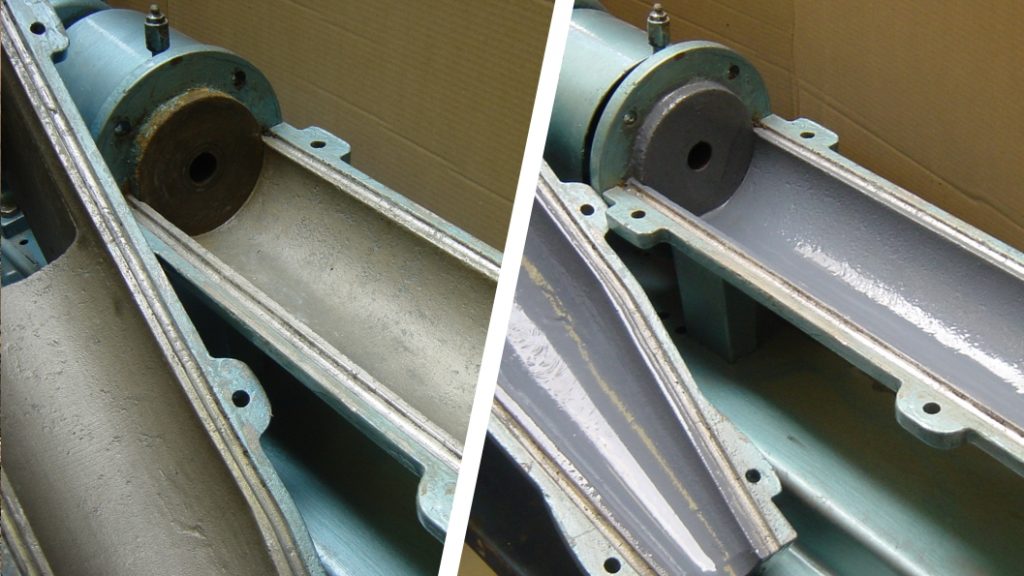

The smoothness of Ceramic Brushable improves the efficiency of systems such as chutes and mining equipment by reducing friction and making clean up more effective. Ceramic Brushable can also be used to top coat rougher repair compounds like WearShield Epoxy Paste.

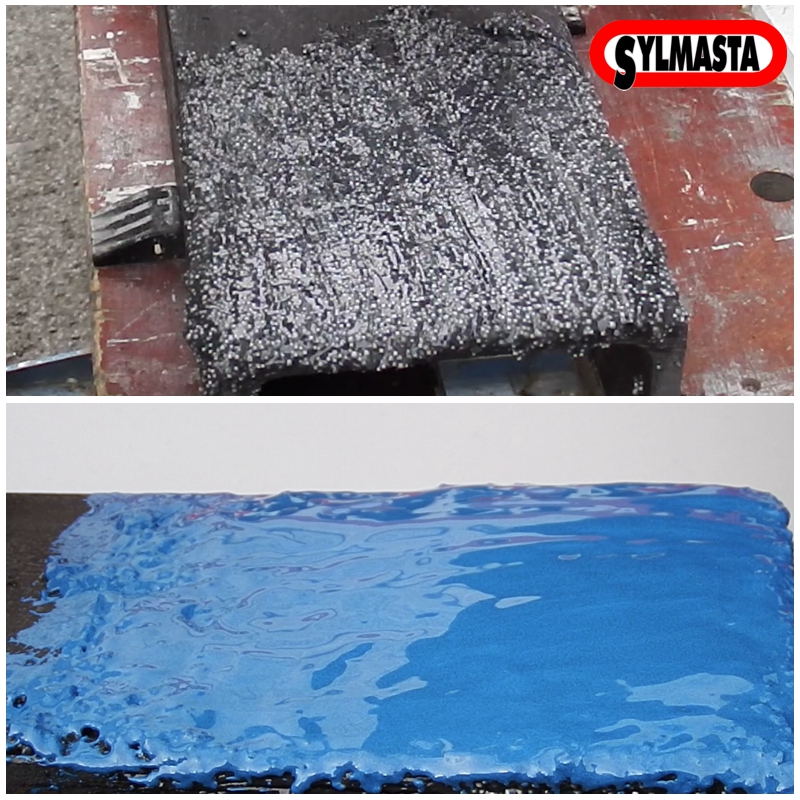

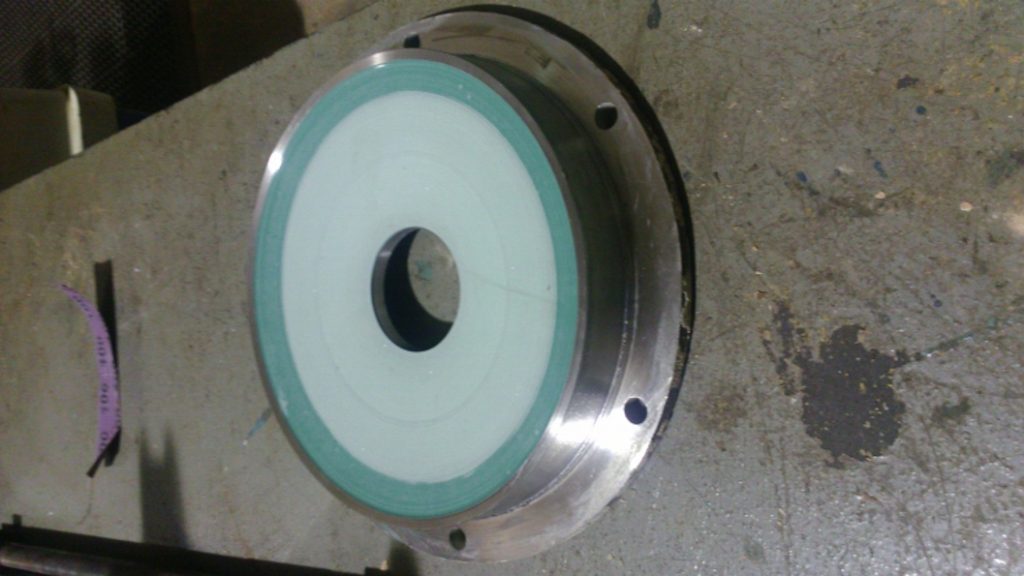

Ceramic Brushable is available in blue, green and black colours as standard. Using two colours in conjunction creates a two-layer wear indicator coating.

With a 45 minute gel time, Ceramic Brushable can be mixed in larger quantities without the worry that it will cure before application is completed.

How to protect surfaces with Ceramic Brushable Epoxy Coating

Prior to applying Ceramic Brushable, surfaces should be free of paint, rust and grime before being roughened up through either grit blasting or grinding with a coarse wheel or abrasive disk pad.

Full instructions detailing the preparation process can be found on the Technical Data Sheet and are provided with the product.

Ceramic Brushable should be applied as soon as the preparation procedure is completed. To ease the mixing process, the resin container has enough room to dispense all the hardener straight into. It can then be applied with a brush direct from the container.

Each coating of Ceramic Brushable should be 0.5-1.00mm thick. To ensure a pinhole-free coating, at least two coats are needed.

Ceramic Brushable re-coating time is approximately 4-6 hours after applying. A full functional cure is achieved 24 hours after the final coat at 22°C.

The light consistency of Ceramic Brushable makes it easy to mix and apply with little sag. It is virtually odourless, with no unpleasant smell, can be easily machined and is temperature resistant to 150°C.

To create a two-layer wear indicator coating, a topcoat of one colour of Ceramic Brushable is applied over a base coat of another colour. When the base coat colour begins to show through, it is an indication of high-wear. Another coating of epoxy should be added for further protection.

Benefits of Ceramic Brushable Abrasion Resistant Epoxy Coating

- Easily mixed and applied – just paint onto a surface using a brush

- Protects against abrasion, corrosion and cavitation

- Creates an ultra-smooth, glass-like finish to all surfaces

- 45 minute gel time allows for complex jobs to be carried out

Applications

- Protecting new equipment from wear and corrosion

- Providing a final topcoat over repaired surfaces and rougher epoxy compounds

- Protecting silos, chutes, mills, pumps, impeller blades, valves, fan blades, metal castings, tanks and other machine parts in abrasive environments

- Increasing resistance against corrosion and chemical attack

- Creating a two-layer wear indicator coating