In this video, we take a look at the formulation of WearShield Epoxy Paste and explain how its interlocking structure makes the cured material so resistant to wear, abrasion, corrosion and impact damage.

About this Epoxy Paste Video

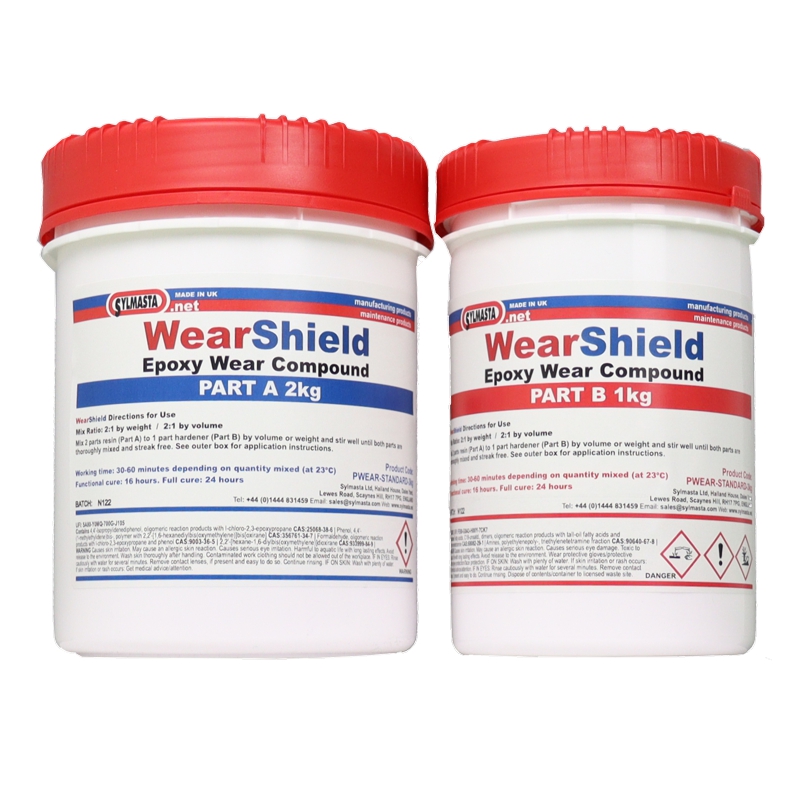

WearShield Epoxy Paste is used in some of the most abrasive working environments in the world to protect plant equipment and surfaces from damage caused by wear, impact, abrasion and corrosion.

It was originally formulated for the tough requirements of the South American mining industry. The increasing cost of American-made epoxy compounds led a mining company in Chile to approach Sylmasta about formulating an alternative.

The use of WearShield quickly spread across the continent. It is now used worldwide to protect heavy machinery including pumps, ash handling systems, scrubbers, silos, chutes, mineral nozzles, agglomerator drums, trunions and metal castings.

In the above video, we explain how the formulation of WearShield makes it so resistant. The epoxy paste is heavily filled with hard wearing alumina beads in a range of sizes. Large beards protect against bigger particles and little beads against smaller particles.

These beads combined with the high resin content of WearShield create a dense interlocking structure. Once cured, WearShield provides an alumina-reinforced, hardened shell up to 6mm thick for ultimate protection to the original substrate.

The video also shows product testing carried out at Sylmasta HQ. WearShield was applied to a metal demo piece. Once fully cured, it was attacked with an angle grinder for abrasion and impact testing. There was no chipping or fracturing of the cured WearShield.

Two grades of WearShield are available. Standard comes with a work time of between 30 and 60 minutes, a functional cure of 8–12 hours. and a 24-hour full cure.

It is used at higher ambient temperatures or where large amounts of WearShield are being mixed at once, removing the threat of premature curing from the application process.

WearShield Rapid is the fastest-working epoxy wear compound available. It begins to harden in just 10 minutes, significantly reducing system downtime and disruption.

WearShield Epoxy Paste

WearShield Impact Resistant Epoxy Paste

Alumina bead-filled epoxy paste which forms a toughened layer of protection against impact damage and wear

WearShield Rapid 5 Minute Epoxy Paste

Fast working version of WearShield with a three-hour full cure, reducing equipment downtime

If you have an application you would like to enquire about, then please get in touch

Call: +44 (0)1444 831 459

Email: sales@sylmasta.com