This repair video shows how to refurbish rusted metalwork and protect it from future corrosion by using Liquid Metal Epoxy Coating to create a new, hard wearing surface over the weakened original substrate.

About this Epoxy Coating Video

Liquid Metal is a metal-filled epoxy coating used to refurbish and protect metalwork and plastics against corrosion and chemical attack.

It is brush-applied onto pipework, equipment and other surfaces. It sets to form a smooth, metallic, hard-wearing outer shield which acts as a barrier protecting the original substate from attack.

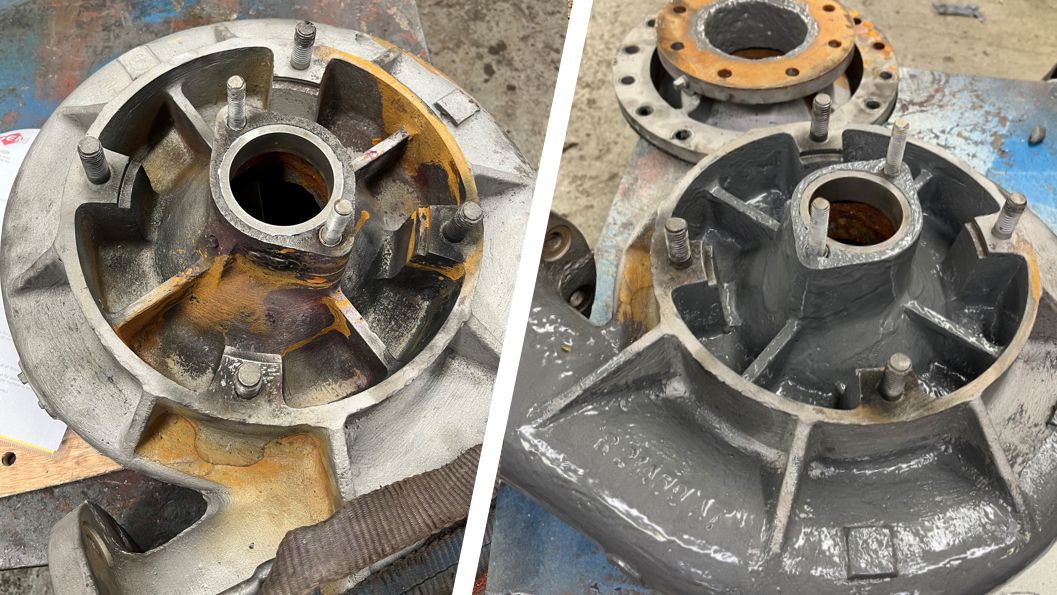

For this demonstration video filmed at Sylmasta HQ, we took a heavily corroded carbon steel industrial barrel and refurbished it using Liquid Metal. The repair strengthened the brittle metalwork and helped prevent future corrosion.

Before application of Liquid Metal, the carbon steel underwent surface preparation. A power brush was used to remove as much rust, grime and remains of previous coatings as possible.

The two parts of Liquid Metal were then easily mixed by pouring the hardener (Part B) straight into the resin (Part A) container. The coating was stirred using a spatula until streak-free and a consistent grey colour.

Liquid Metal was then painted onto the barrell using a brush. Its high initial tack and adhesion enabled it to easily adhere to the steel barrel.

The coating applied was 1mm thick. Liquid Metal has a gel time of 90 minutes and a re-coat time time of between five and eight hours. To speed up the cure, a hot air gun was used evenly across the entire repair.

Once Liquid Metal had cured, the barrell was left with a high gloss, corrosion resistant coating. Additional layers of Liquid Metal could have been painted on, each building up the thickness of the outer shield

In pipe repair applications, Liquid Metal can be further reinforced by overwrapping with SylWrap Pipe Repair Bandage. SylWrap is added whilst Liquid Metal remains tacky. The epoxy coating will then improve adhesion between the pipe and the bandage.

SylWrap will cure within minutes to form a thickened, rock hard, impact-resistant shell around the pipe for even more enhanced protection levels.

This repair method using Liquid Metal and SylWrap is regularly used by water and wastewater companies to refurbish severely weakened pipe bridges.

The expense of removing and replacing such huge structures can otherwise reach six figures and require complex projects which take months to complete.

Liquid Metal and SylWrap in contrast will refurbish many metres of pipe bridge more cost-effectively and in a fraction of the time.

Liquid Metal

Liquid Metal Epxy Coating

Brush-applied epoxy coating forms a smooth, hard-wearing, metallic layer to protect original parts and surfaces

Liquid Metal Case Study

Case Study: Worthington Simpson Pump Repair Seals Pinhole Leaks in Casing

If you have an application you would like to enquire about, then please get in touch

Call: +44 (0)1444 831 459

Email: sales@sylmasta.com