Sylmasta epoxy putties, pastes and coatings are used to repair and rebuild surfaces, structures and machine parts suffering from damage, instead of carrying out expensive replacements of parts and machinery.

The following Case Studies highlight how individuals happy to carry out their own DIY repairs and industrial users have been able to save significant amounts of money thanks to products provided by Sylmasta and technical assistance in formulating and advising on repair methods.

If you have any questions about any of the solutions supplied by Sylmasta or require help with an application of your own, then please contact us and a technician will be happy to assist you.

Case Study: Using Epoxy Putty for Cracked & Damaged Brick Repair & Restoration

Bricks suffering from cracks, holes and missing chunks as a result of lime blow are seamlessly repaired using epoxy putty coloured with brick dust at a site in the south of England

Case Study: CAE1500 With a Miracle Decoration Repair to Save a Family’s Christmas

Sylmasta CAE1500 Superglue saves Christmas for a family with the repair of a decoration passed down through generations which had been accidentally snapped in two

Case Study: Refurbishment & Repair of Power Plant Condenser Unit Deformed by Corrosion

Ceramic Supergrade rebuilds the cast iron face of a 20-year-old condenser unit deformed by heavy corrosion at a power plant in Puerto Rico, extending the lifespan of the part

Case Study: Corroded Tank Repair at a Puerto Rico Pharmaceutical Plant

A heavily corroded industrial tank at a pharmaceutical plant undergoes repair and refurbishment to extend its lifespan by several years ahead of a planned replacement

Case Study: Magic Corner Kitchen Unit Repair Saves Over £200 in Replacement Costs

The high-strength bonding properties of Superfast Steel Epoxy Putty Stick repair a damaged magic corner kitchen unit which would have cost £290 to replace

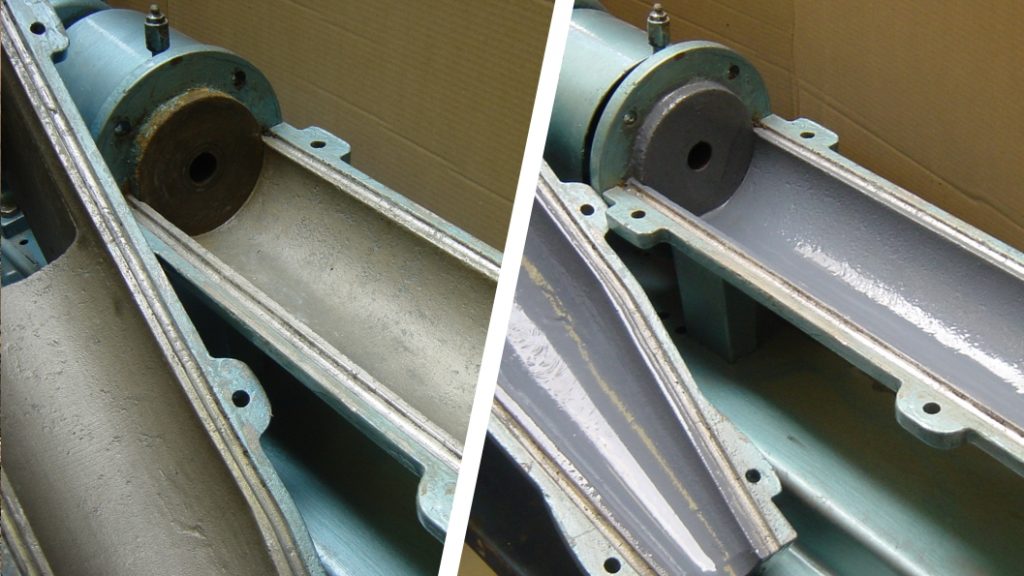

Case Study: Creating an Abrasion Resistant Surface for Pug Mill Extruder Barrels

Ceramic Brushable Blue is used to coat pug mill putty extruder barrels, creating an abrasion resistant surface to increase extrusion efficiency and protect against future wear

Case Study: Repair & Refurbishment of a 19th Century Pit Wheel at Mordiford Mill

Sylmasta AB provides a waterproof, corrosion resistant material to protect a 19th century pit wheel from water ingress and help bond two steel hoops to its castings for reinforcement

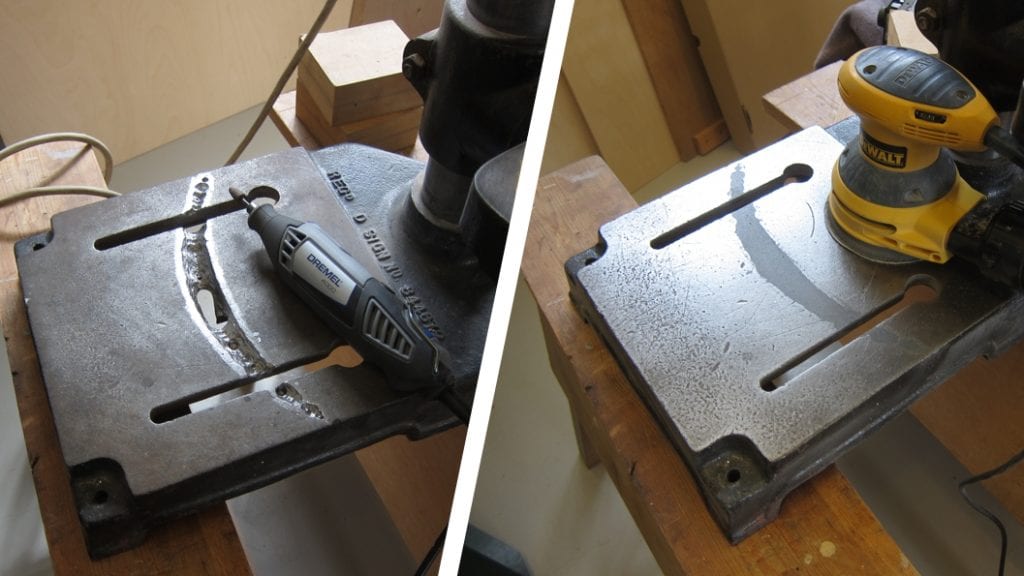

Case Study: Industrial Metal Repairs a Large Gouge to Refurbish a Drill Base Stand

A drill base stand undergoes refurbishment and repair with Industrial Metal used to seamlessly fill in a significant gouge caused by a previous owner’s misuse

Case Study: Chip Filler Repair to a Damaged £500 Designer Bar Stool Made of SMC

A homeowner quoted £220 to fix a chip in a £500 designer bar stool made of SMC instead made a cost-effective DIY filler repair using Sylmasta AB Epoxy Putty

Case Study: Repair of Metal Blades in Bakery Flour Mixers Suffering From Heavy Corrosion

Sylmasta save a bakery in Puerto Rico a load of dough by providing a cost effective and quick repair to heavily corroded blades in a flour mixer which would otherwise have needed replacing

Case Study: Heavily Damaged Metal Machinery Repair Saves a Puerto Rico Ball Mill $60 million

The downtime on a damaged machine at a Ball Mill in Puerto Rico looked like it would cost a company approaching $60 million until Sylmasta provided a repair