Sylmasta epoxy putties, pastes and coatings are used to repair and rebuild surfaces, structures and machine parts suffering from damage, instead of carrying out expensive replacements of parts and machinery.

The following Case Studies highlight how individuals happy to carry out their own DIY repairs and industrial users have been able to save significant amounts of money thanks to products provided by Sylmasta and technical assistance in formulating and advising on repair methods.

If you have any questions about any of the solutions supplied by Sylmasta or require help with an application of your own, then please contact us and a technician will be happy to assist you.

Case Study: Rotted Bay Sash Window Frame Repair & Restoration

A bay sash window frame rotted just eight years after installation is cleaned, stabilised and rebuilt in a repair made by the homeowner leaving no trace of damage

Case Study: Leaking HVAC Cooling Tower Repair at Production Facility in USA

After several failed repair attempts, a leaking HVAC cooling tower at a production facility is sealed within a matter of hours to restore full efficiency to the temperature control system

Case Study: Restoration of Clan MacGregor Dalmally Burial Stones Dated 1390-1528

Sylmasta manufacture a specialist version of AB Original Epoxy Putty colour-matched to RAL 7037 to help with the restoration of the Clan MacGregor Dalmally Burial Stones

Case Study: Landscaping Materials Company Repair & Protect Warehouse Metal Pallets

A landscaping materials supplier repair metal pallets at their warehouse damaged by having heavy and abrasive items like paving, slabs and stones stacked on them

Case Study: Classical Composite Order Column Restoration at Former Cinema Built in 1920s

Damaged concrete classical composite order columns are returned to their detailed original state during the renovation of a 1920s neoclassical style former cinema

Case Study: Corroded 30-Metre Section of Sewer Force Main In Underground Vault Repair

An engineering company in Hawaii refurbish a 30-metre section of corroded 450mm ductile iron sewer main after a previous repair attempt left a 30mm hole in the pipe

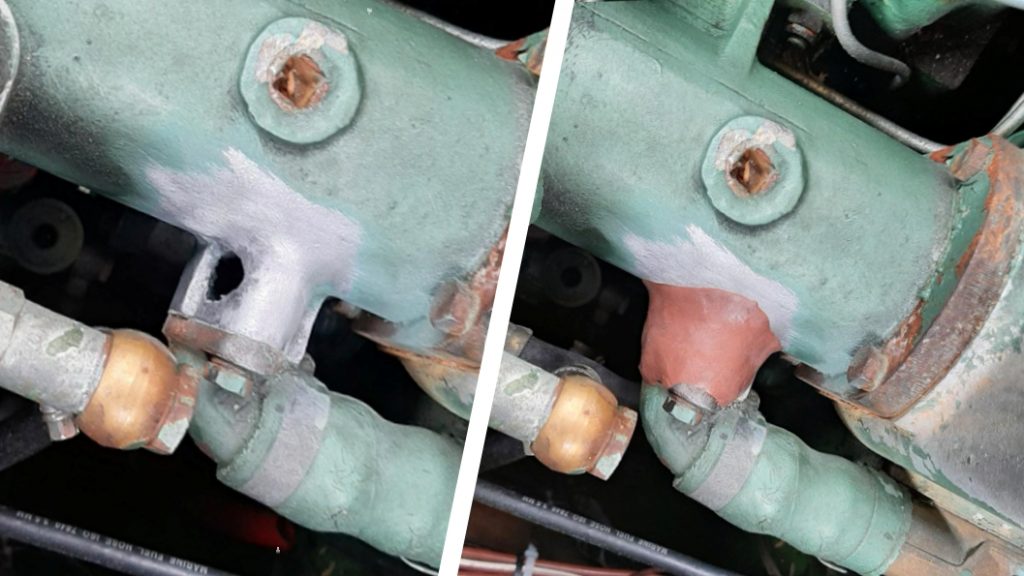

Case Study: Narrowboat Engine Heat Exchanger Manifold Hole Repair With Superfast Titanium

A narrowboat owner repairs a 15mm x 15mm hole in the engine heat exchanger manifold of their vessel using Superfast Titanium Epoxy Putty Stick

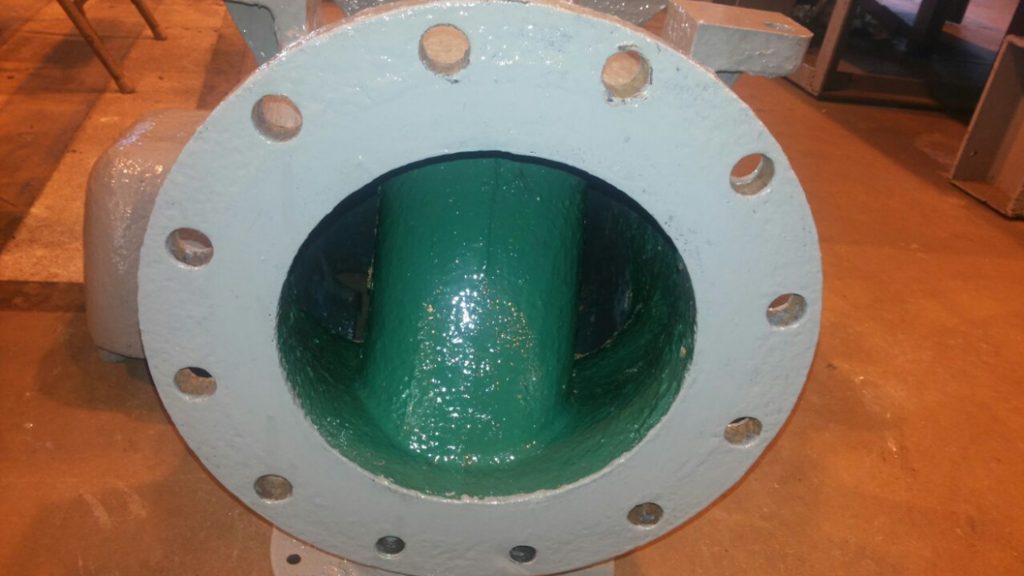

Case Study: Copper Mine Repair Pump Housing Heavily Damaged By River Water Extraction

Pump housing left with corrosion, abrasion and wear damage after years of extracting river water full of sand, silt and other debris is repaired at a copper mine in Bulgaria

Case Study: Rotted Wooden Beam Repair in Home Renovation Project

Large voids in a rotted wooden beam are filled to create a flat, smooth surface enabling the outside of a house to be rendered as part of a renovation project

Case Study: Reassembly & Repair of Composite Stone Water Fountain Cracked into Pieces

The upper bowl of a tiered composite stone water fountain which cracked into multiple pieces during freezing winter weather is reassembled and repaired by its owner

Case Study: Seawater Storage Tank Floor Repair at Gas Processing Plant in Saudi Arabia

Gaps between rubber sheets covering the floor of a seawater storage tank at a gas plant are filled in to protect the exposed concrete coating the bottom of the tank

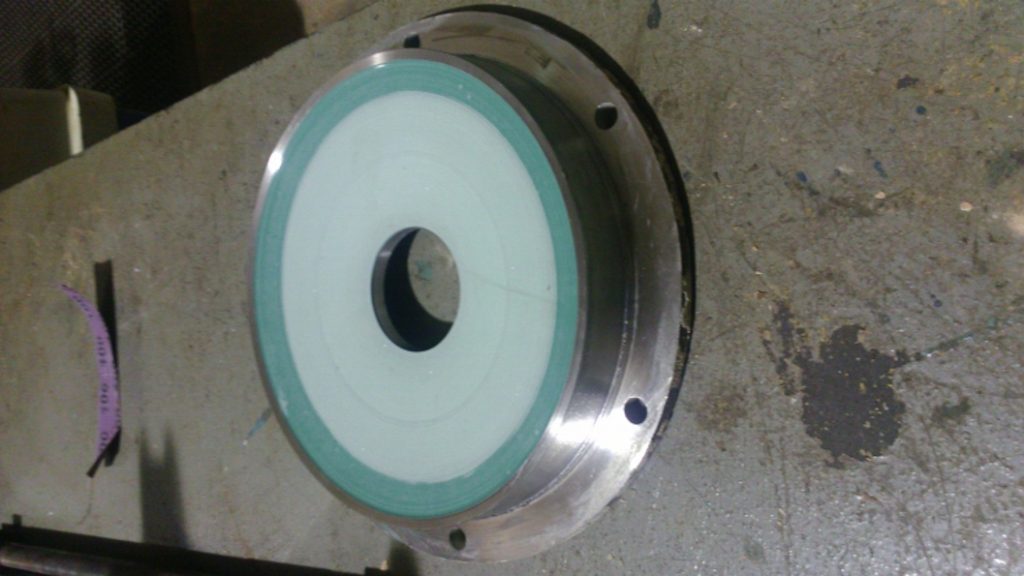

Case Study: Power Station Repair Damage to Alloy 20 Pump Lid Caused by Impeller

A pump lid made from Alloy 20 at a power station treatment plant undergoes repair instead of a $4000 replacement after being damaged by a falling impeller

Case Study: Underwater Wall Between River & Trout Farm Crack Repair

The Environment Agency seal a 700mm long crack in an underwater wall discovered when abnormal levels of water were monitored passing from a river into a trout farm

Case Study: Fence Spurs Suffering from Concrete Cancer Filler Repair Using Epoxy Putty

Spurs suffering from concrete cancer which began disintegrating during the replacement of a trellis fence are repaired and rebuilt using Sylmasta AB Original Epoxy Putty

Case Study: Reinforcement of Heavily Corroded Steel Pipe to Avoid Future Leak Repair

A heavily corroded section of steel pipe is reinforced, helping a site to avoid a future breach which would have required a costly and disruptive leak repair or replacement of the line

Case Study: Permanent Mortar and Pestle Repair Made Using Epoxy Adhesive

A granite pestle cracked into two parts is permanently bonded back together, giving its owner many more happy years of preparing ingredients using their favourite kitchen tool

Case Study: Water Treatment Plant in Puerto Rico Repair Worn Pump Extracting from a Well

Ceramic Brushable Green provides a long-term repair solution for a pump which had become badly worn due to minerals and sediments in the water it extracted from a below-ground well

Case Study: Ceramic Mill Wheel Worn Shaft Repair & Rebuild After Replacement Deemed Impossible

A ceramic factory rebuild a heavily worn shaft on a mill wheel after being told replacing the damaged part was not possible and so the only solution was fitting a whole new wheel

Case Study: Rapid 5 Minute Epoxy Adhesive Used to Repair Broken Ceramic Teapot Lid

Rapid 5 Minute Epoxy Adhesive accurately repairs a ceramic teapot lid which had broken into two pieces when it was accidentally dropped onto a hard floor

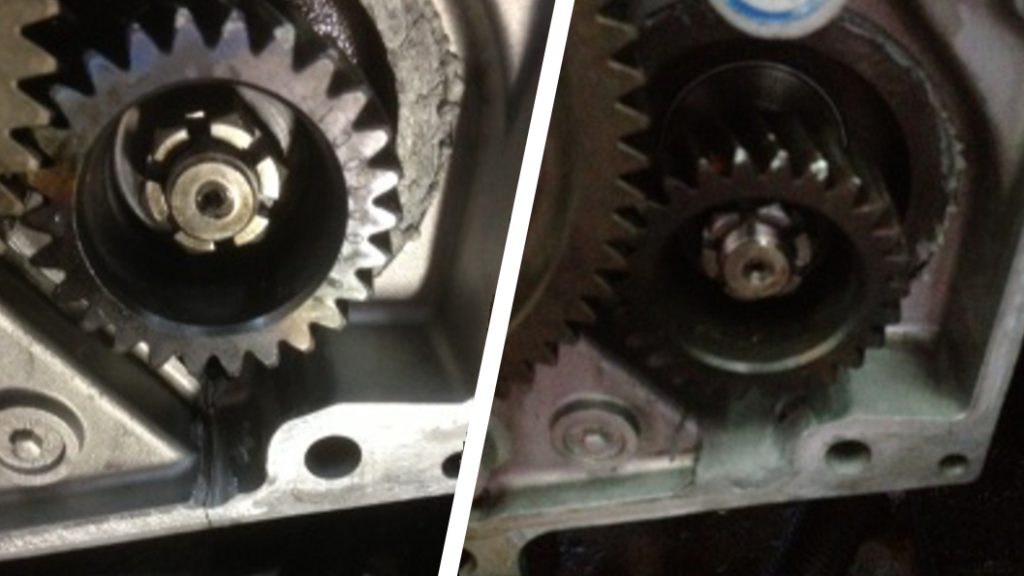

Case Study: Dairy Delivery Truck 466 International Engine Cracked Timing Cover Repair

Industrial Metal saves a Puerto Rico milk company spending $1000 on a new timing cover for one of their delivery trucks by repairing a crack through which oil was escaping

Case Study: Superfast Steel Epoxy Putty Used to Fix Rust Holes on a Classic Car

A classic car owner uses Superfast Steel Epoxy Putty to permanently fix rust holes which had developed on the metal frame of their vehicle in a quick, easy and cost-effective repair