The SylWrap range of leak repair products and the Sylmasta Pipe Refurbishment System provide permanent live leak repair, corrosion protection, pipeline strengthening and reinforcement, surface damage repair, and pipe profile restoration.

The following Case Studies highlight projects Sylmasta have been involved with, working with water companies, infrastructure operators, facilities management, multinational corporations and government departments as well as small businesses and individuals across a range of different sectors.

If you have any questions about any of the solutions supplied by Sylmasta or require help with an application of your own, then please contact us and a technician will be happy to assist you.

Case Study: Major Repair Programme for Critical Pipeline at Mexico Water Treatment Plant

A major repair programme at a wastewater treatment plant in Mexico seals multiple leaks and strengthens a critical 300mm diameter steel pipe running through the site

Case Study: 80mm Diameter Hole in Cast Iron Wastewater Drain Pipe Repair at Hospital

An 80mm hole in a cast iron wastewater drain pipe connected to a hospital bathroom is sealed in a repair which needed the facility to close for just 15 minutes

Case Study: Protection of Underwater Gas Pipe Network Laid Through River System

SGN protect a network of underwater gas pipes running through rivers in Scotland which became exposed when gravel washed away, leaving them vulnerable to damage

Case Study: Cast Iron Waste Pipe U-Bend Crack Repair Above Hospital Corridor

A cast iron waste pipe with a hairline crack in a U-bend is repaired within the confines of a cramped roof space above a hospital corridor by a maintenance worker on top of a ladder

Case Study: Complex in UAE Approves SylWrap for Chilled Water System ABS Pipe Repair

Following rigorous testing, Superfast Aqua PW and SylWrap HD are approved for repairing leaking ABS pipe joints in a chilled water system at a luxury complex in the UAE

Case Study: Leaking HVAC Cooling Tower Repair at Production Facility in USA

After several failed repair attempts, a leaking HVAC cooling tower at a production facility is sealed within a matter of hours to restore full efficiency to the temperature control system

Case Study: Repair of Underground Clay Drainage Pipe Cracked During Building Work

Two cracks in an underground clay drainage pipe – one of which was severe enough to almost split the pipe into two – are sealed by a UK homeowner making a DIY repair

Case Study: SylWrap Leak Repair Passes ASME PCC-2 402-III Qualification Standard

A leak repair using Superfast Aqua PW Epoxy Putty and SylWrap HD passes testing for ASME PCC-2 402-III Qualification – Validation for Repair of Leaking Component

Case Study: SylWrap Pipe Repair Passes ASME PCC-2 401-III Qualification Standard

A pipe repair using SylWrap HD and Industrial Metal is independently tested to exceed 309.6 bar, passing ASME PCC-2 401-III qualification

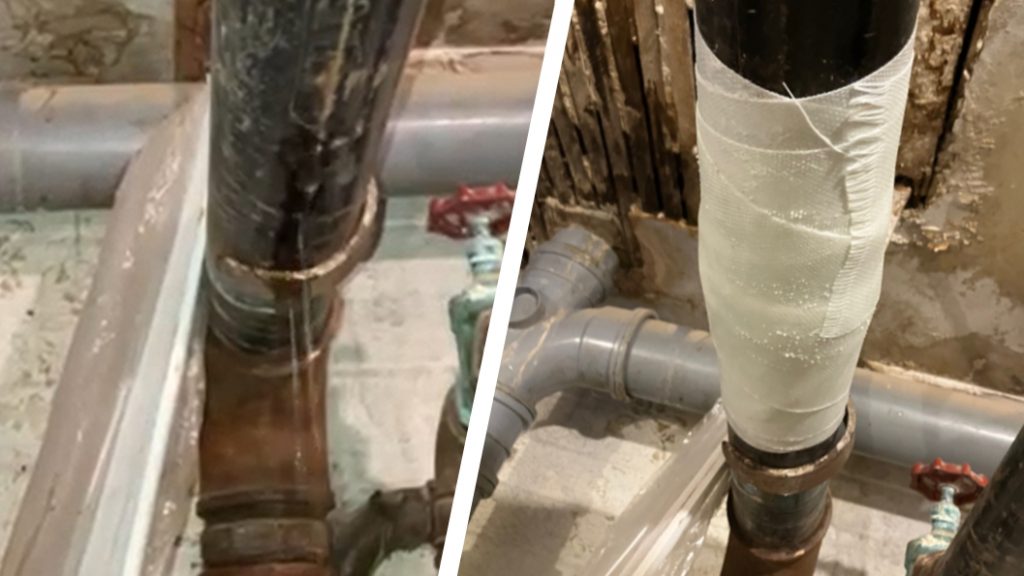

Case Study: 150mm Cast Iron Soil Pipe Repair Leaking in Hospital Roof Space

A cast iron soil pipe leaking through a two-metre horizontal crack is sealed in a confined roof space, preventing wastewater escaping into the hospital ward below

Case Study: Aluminium Conduit Pipe Carrying Cables Underneath Train Repair

Aluminium conduit pipes carrying cables underneath a train are repaired and reinforced after being damaged by ballast flying up from the railway track bed

Case Study: Repair of Domestic Water Main Pipe Leaking Due to Stone Damage and Corrosion

Corrosion and stone damage left a domestic water main pipe leaking underneath a driveway until the homeowner repaired and refurbished a 2-metre section of the line

Case Study: Leaking Dishwasher 50mm Plastic Pipe Repair in Golf Clubhouse Kitchen

A dishwasher pipe in a golf clubhouse discovered to be leaking on Sunday morning is repaired in under 30 minutes, ensuring no disruption to the busy luchtime service

Case Study: Repair of Leaking Expansion Joint Fitted to Water Main Pipe on UK Road Bridge

An expansion joint on a 225mm steel water main carried over a river by a major road suspension bridge is repaired after it began leaking from a split between two bellows

Case Study: Bilge Pipe Leaking Through Corroded Welded Joint Repair On Board Superyacht

A leaking bilge pipe on board a multimillion dollar superyacht is repaired after corrosion caused a hole to appear in a welded joint where it was impossible to fit a clamp

Case Study: Corroded 30-Metre Section of Sewer Force Main In Underground Vault Repair

An engineering company in Hawaii refurbish a 30-metre section of corroded 450mm ductile iron sewer main after a previous repair attempt left a 30mm hole in the pipe

Case Study: Emergency Live Leak Pipe Repair Keeps Heating on at Nursing Home

A nursing home avoids having to shut down its heating system in winter by making a live leak repair to a 150mm metal pipe which otherwise would have flooded a loft space

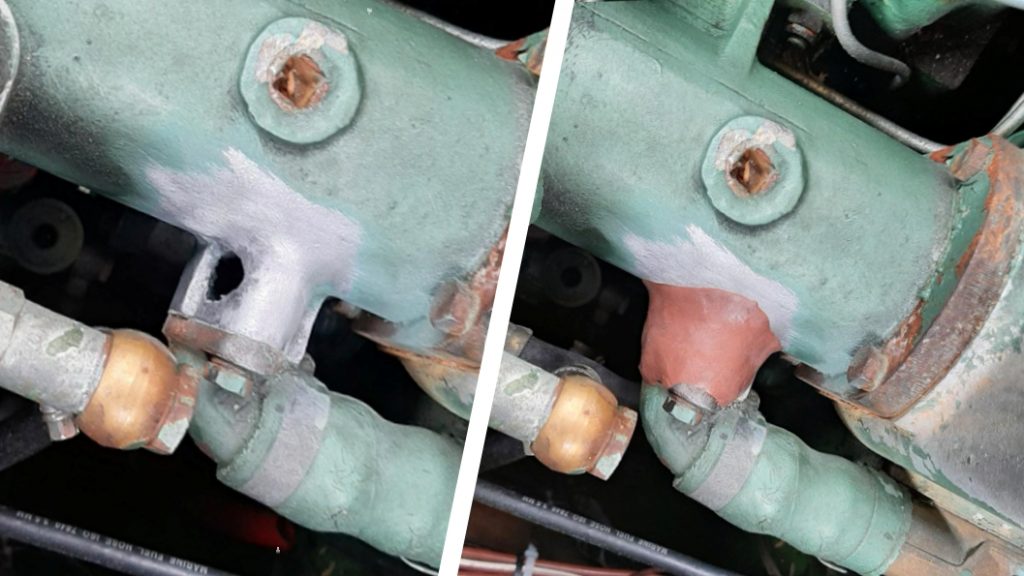

Case Study: Narrowboat Engine Heat Exchanger Manifold Hole Repair With Superfast Titanium

A narrowboat owner repairs a 15mm x 15mm hole in the engine heat exchanger manifold of their vessel using Superfast Titanium Epoxy Putty Stick

Case Study: Oil Refinery Repair Cooling Pipe System Attacked by Microbially Induced Corrosion

An oil refinery carry out a significant pipe repair programme after microbially induced corrosion caused welded joints in the stainless steel water cooling system to fail

Case Study: 6 Bar Live Leak Repair to 300mm Steel Pipe at Malaysia Water Treatment Plant

One week after a series of demonstrations and site visits from Sylmasta in Malaysia, a water company repair a 6 bar live leak on a 300mm steel pipe at a treatment plant

Case Study: Underground 600mm Concrete Water Pipe Break Repair in Canada

A city authority in Canada repair a break in an underground 600mm diameter concrete pipe at the point it passed through a wall, significantly reducing levels of water loss